- Packing - Handling - Logistics >

- Conveying >

- Pneumatic conveying systems

Pneumatic conveying systems

The dense phase conveying technology, using compressed air as the power, through the transmission tank and pipeline, the materials to a certain height or distance outside the container, involving pressure vessel, fluid mechanics, material ...

Shanghai Tandy Machinery Manufacturing Co.,Ltd.

Among DENA wide range of pneumatic conveyors there are solutions from 2,0 to 45 kW efficiency, with conveying distances up to 200 mt and rate flow beyond 10t/h. They are the ideal technology to transfer big quantity of bulk materials, ...

dena aspirazioni industriali

DUST FREE VACUUM CONVEYING Dust-free powder conveying automatic design pneumatic vacuum conveyor system environmental friendly design. Jubao Intelligent BVC series dust free powder vacuum conveying system is one kind of new design ...

For the conveying of filtered-out materials to silos or containers. Pneumatic low-pressure conveyor systems For the conveying of filtered-out materials to silos or containers and for conveying distances of up to 200 m. The conveying ...

Rippert GmbH & Co. KG

For different needs such as material packaging, handling, dosing, product mixing, distribution on different production lines, Mastervac offers compressed air or electrically powered pneumatic transport systems that can move various types ...

AIRPULS dense phase pneumatic conveyors, at high and very high concentration, are manufactured in several standard versions to guarantee granules pneumatic conveying according to the requirements. They are proposed in two different categories ...

Storch Magnetics serves all types of industries including Manufacturing, Robotics, System integrators and processing companies since 1952. We are a certified ISO 9001:2015 & WBENC company that continues assisting industries with their ...

Suction and vacuum transport of swarf with an aeraulic network SFH designs and manufactures chips processing lines dedicated to increasing their value in recycling channels and to re-using cutting fluids. Our assets Vacuum suction ...

PRODUCT FEATURES Rated power range of 3.1 – 3.7 kW Thrust range of 430 - 460 N Solids removal Mixing and flushing Non-clogging test content Dual, superior performance Flygt hydro ejectors perform two different operations depending ...

Jabsco

PROPULSIVE MACHINE SUITABLE FOR THE PNEUMATIC TRANSPORT (IN SHORT AND MEDIUM ROUTE) OF MATERIAL IN A SOLID PHASE, AND FOR THE MATERIAL TRANSPORT WHERE IT IS NECESSARY TO KEEP SAFE THE PRODUCT ENTIRETY. TECHNICAL FEATURES » loading ...

Product Introduction of Pneumatic Conveying Equipment: Pneumatic Conveying Equipment, which takes Roots blower as the air source, is designed specifical for close distance and continuous transporting. Transporting distances is generally ...

PIP-type feed conveyor for pneumatic dense-phase conveying by pushing. Thanks to their high load capacity and low operating speed damage to the transported goods is minimised. They are particularly suitable for sensitive or abrasive bulk ...

HOSOKAWA SOLIDS, S.L.

The pneumatic conveying systems are designed exclusively to meet the customer’s needs, depending on space requirements, distances and desired production capacity. The air-conveying system consists mainly of inox pipelines F50 & F63.5. The ...

Pneumatic suction conveyor systems are an important component in the production of high-quality products in modern plastic processing. The automated material supply with granulates, masterbatches and grinding media ensures high plant ...

Tschritter GmbH

Pneumatic conveyors ideal for conveying powders and granules Pneumatic conveyor systems are perfectly operating in locations classified ATEX Seals and filters certified FDA Designed and produced in three sizes so as to carry up to 14,000 ...

THE KNOW-HOW OF STAWIMPIANTI, PRESENT ON THE MARKET FOR 25 YEARS, HAS BEEN LEADING IN THE CONSTRUCTION AND DESIGN OF PNEUMATIC TRANSPORT SYSTEMS IN DENE AND IN DILUTED PHASE, EXPLOITING THE PRESSURE OF THE TECHNICAL GASES (AIR OR NITROGEN) ...

Knowing and understanding pneumatic conveying systems helps in making decisions when choosing one technology or another. Equipos y Procesos Levante has the experience to design and offer the ideal pneumatic conveying systems for each ...

The transport of materials from point A to point B represents a significant phase for the production processes of all product sectors. The types of material can be the most varied: from powders, to granules, up to small objects such as ...

The pneumatic express courier... whips your precious objects from A to B. A piece of pipe is coming to life when such a “pipe vacuum ejector“ is put in between. Through angular drills the vacuum is created in the DF by ...

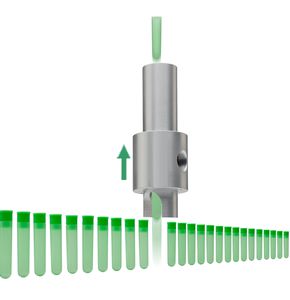

- In-line venturi specialized for pneumatic conveying - Ø of passage : from 4 to 100 mm Features: - In-line venturi with straight duct specialized for pneumatic conveying - Fully static, instant start and stop - To be installed ...

- Specialized in-line venturi for pneumatic conveying, without seal, made of 316L stainless steel - Ø of passage: from 4 to 75 mm Features: - In-line venturi with straight duct specialized for pneumatic conveying of material and ...

It is used for large capacity and long distance conveying of PP, PE, PS, PVC, PC, POM and other granular or powder products. The conveying capacity range can be up to 120t/h and the distance can be further than 500m. We can provide systems ...

ONGOAL TECHNOLOGY CO., LTD.

The MAI®4SILO-BOX pneumatic dry mortar conveying system The right conveying machinery is important for the optimisation of results on construction sites and MAI pneumatic dry mortar conveying systems offer easy and maintenance-free operation. When ...

Mai International

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining