- Machine-tools >

- Machine Tool Accessory >

- Machine feed

Machine feed

Euro ColorMix is a distribution system for concrete of different colours with two, three or four hoppers for colors assembled in the same frame. After receiving the colored concrete, Euro ColorMix distributes it on a conveyor belt and ...

Euromecc’s new eco-hopper for clinker unloading using grab cranes is based on the company’s other designs for the cement and coal industries developed over the last two decades. These bespoke concepts have increased Euromecc’s bulk materials ...

We realize hoppers for the conveying of loose materials with several sizes, according to the customer needs.

Trailing cable - Cable trolley inside profile or on steel beam - For contaminated or humid environment - Cost effective solution for monorail - Suitable for outdoor use - Option: equipped with compressed-air supply C-rail with ...

SAFE, EFFECTIVE SYSTEM The Meier automatic feeder guarantees a continuous level of adhesive inside the tanks of melters, saving the user from having to carry out manual filling.

Twin Screw Feeder NXT26 The NXT26 feeder is ideal for poorly flowing, sticky powders as well as fibers and granules. The feeder has the following main components: a screw trough with negative wall angle structure, a gearbox, an inclined ...

Kubota Brabender Technologie GmbH

Twin Screw Feeder NXT45M The NXT45M feeder is ideal for difficult, sticky powders as well as fibers and granules. The feeder has the following main components: a screw trough with negative wall angle structure, a gearbox, an inclined ...

Kubota Brabender Technologie GmbH

FlexWall® 20 - Universal loss-in-weight feeder for virtually all flowable ingredients (powders, pellets, flakes, fibers, etc.) - Flexible polyurethane hopper agitated by amplitude adjustable paddles for consistent screw filling and ...

Kubota Brabender Technologie GmbH

The ADS 112 wire pull machine is ideal for the optimum feeding of wires from reels, Conipacks or drums. Wire is transported by two synchronous toothed belts. For wound or unbending wires, a perfect supplement to the wire force machine ...

Komax AG

The Komax Wire ads 115 is a wire feeding system that can deliver rapid processing speed due to its storage design. It can exhibit simultaneous control of the de-reeling speed and is available in wide array of feedable round / ribbon cables. ...

Komax AG

The Ads 119 Model is a wire feeding system developed by Komax Wire. It comes with a gentle active wire feed and short conversion time. This products operates quietly and smoothly. It also integrates a passive wire return safety device. ...

Komax AG

KMT Waterjet Systems ADS Series Abrasive Hoppers - 500 lb. and 2,000 lb. Containers • KMT Waterjet Abrasive Delivery System (ADS) is used for waterjet cutting machines to ensure production reliability with constant abrasive flow rates. • ...

•Abrasive Flow Monitoring Saves Time and Costs Our 500 V HOPPER precisely monitors the availability of sufficient abrasive closely during the entire cutting process and pneumatically transfers it to the onboard metering device. This ...

ABRALINE feeding system is a reliable product. Production reliability requires constant monitoring of the entire cutting process. The economical and successful cutting process depends greatly on a constant abrasive flow rate. This is ...

VAC-U-MAX provides over 65 years of application expertise in handling over 10,000 powders and bulk materials, providing pneumatic conveying solutions for even the hardest-to-handle dry bulk solids including materials with high fat, high ...

Loading a Loss in weight feeder that is operating in a continuous mode requires the right kind of equipment. The objective is to refill the feeder as quickly as possible. VAC-U-MAX offers the fastest way to reload a feeder in the material ...

VAC-U-MAX dump hoppers allow for extended vacuuming times and large-volume recovery of dry materials only. The heavy-duty reinforced containers are constructed of carbon steel with a grey epoxy finish, and are rated for 16” Hg (220” / ...

Principles of the Discharging System NTE Process Circle Feeder is to be attached to the bottom of a hopper or silo. On the bottom panel of the CF, thin, flat vanes rotate. The vanes spread out and move the powder materials to the periphery ...

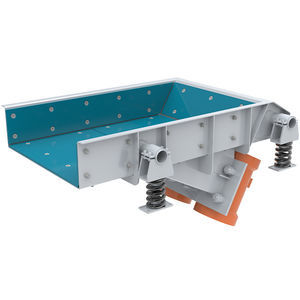

Vibrating Rock Feeders, which feed the raw mines and materials to the crushers, are produced to serve for years in the harsh conditions of the mine sites. They are suitable for material loading with a bucket, truck, or excavator. Made ...

GENERAL MAKINA

Capacity: 20 m³ - 500 m³

The aggregate bunkers used in the first stage of production in concrete plants; for sand and gravel, and aggregate storage in addition to special size crushed stones or mineral materials to feed concrete mixing mixers, regardless of external ...

GENERAL MAKINA

They are bunkers whose volumes can vary between 25 and 100 m³, they are used for sand, crushed stone, aggregate bunkering, which allows this material to be loaded or stocked without any contact with the ground. The feeder bunker truck ...

GENERAL MAKINA

Type 612D - Compact conveyor with rotary paddle cleaning for a material throughput of up to 60 kg/h. The suction vacuum is generated by a powerful collector blower in the conveyor hood. The hood with blower can be opened for maintenance ...

Koch-Technik, Werner Koch Maschinentechnik GmbH

Type TM6D - compact conveyor for two materials and a throughput of up to 60 kg/h. The TM6D compact conveyor is identical in design to the type 612D, but has two material inlets. This allows you to feed your processing machine with ...

Koch-Technik, Werner Koch Maschinentechnik GmbH

Compact conveyor unit for a throughput of up to 50 kg/h This inexpensive conveying device is suitable for island solutions without a compressed air connection and for transporting less dusty granulates. The aspirated material/air mixture ...

Koch-Technik, Werner Koch Maschinentechnik GmbH

The front coal feeding is mainly composed of six parts: rotary equalizer, storage bin, planetary spiral feeding system, pneumatic plug valve, metering chain conveyor and star discharging valve. This system can quantitatively and evenly ...

Walking Floor System is used for temporary storage and uniform discharge of all kinds of waste. The hydraulic-driven walking floor at the bottom of the feed bin enables the material in the bin to move uniformly in one direction. A co-rotating ...

Convenient automatic screw presenter for a wide range of screw types and sizes; both robot-mounted and handheld screwdriver compatible models available.

Janome Industrial Equipment

Convenient automatic screw presenter for a wide range of screw types and sizes; both robot-mounted and handheld screwdriver compatible models available.

Janome Industrial Equipment

Convenient automatic screw presenter for a wide range of screw types and sizes; both robot-mounted and handheld screwdriver compatible models available.

Janome Industrial Equipment

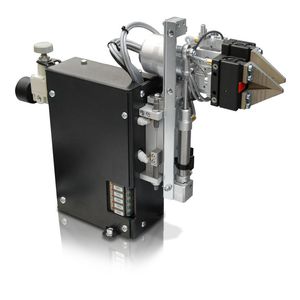

The DRFF-520 Precision Screw Feeder incorporates an adjustable rail which accommodates screw thread diameters from 1.0-5.2mm (#0-#10). A rail adjustment kit is included with the screw presenter to facilitate quick and easy setup. Three ...

Delta Regis Tools

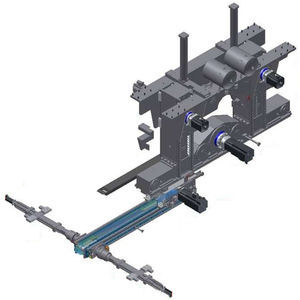

High-speed linear feeder for press interlinking (HSF) • Reliable and proven as well as low maintenance kinematics • The total static load is not taken up via gears, but via linear guides. • The fastest feed rate on the ...

NSM MAGNETTECHNIK GmbH

High-speed hot forming linear feeder (HFF) • Reliable and proven as well as low maintenance kinematics • The fastest feed rate and the highest acceleration values on the market • Drive system Siemens SIMOTION • ...

NSM MAGNETTECHNIK GmbH

• Pushing or pulling operation • Feed angle, pilot release angle and feed length variable • Upper and lower feed rolls hardened, ground, and backlash-free driven: no increased clearance for roll lifting or thicker materials ...

NSM MAGNETTECHNIK GmbH

Apron feeders are used to extract or feed large, lumpy, abrasive and heavy ores under severe impact conditions - including wet, sticky or frozen operations. A robust, heavy duty design provides minimal downtime and many years of service life.

Metso Automation

The smallest feeder in the line, this economical model will give precise feeding of the most minute amounts of materials. It is ideal for feeding a regulated amount of granular to small lump material from a hopper to a second process, ...

Eriez Magnetics Europe Limited

Larger than Model A Feeders, these units use the same patented drive that provides the best linearity in the industry. Special construction is also available for Class II, Group F and G installation.

Eriez Magnetics Europe Limited

Eriez AC operated Hi-Speed Feeders have been designed for exceptionally high speed feeding of light, bulky materials. They provide greater economy and efficiency in feeding, filling, etc., and are ideal for use in conjunction with many ...

Eriez Magnetics Europe Limited

The machine adopts ZG type inertial vibrator as the excitation source, no rotating parts and few wearing parts. When installing, the tank body is properly inclined and installed (generally inclined downward by 10-15 degrees), which can ...

In the crushing production line, this product can continuously and uniformly feed the crushing machinery, and initially screen the materials. A closed structure body can be used to prevent dust pollution. The vibrating feeder is composed ...

Minimum pulling capacity 3 kg Machine made from stove-enamelled sheet steel. Two wheels and two self-locking castors. Accommodates cable diameter min. Ø5mm, max. Ø14mm. Drum-locking system with toothed shaft. Six-way accumulator ...

Capacity: 1 m³ - 2 m³

Back filling with confidence The best tool to fill trenches with gravel and/or sand. The Sand Unit even fills trenches from 40mm width with well consolidated sand, even when moist. Suitable for tractors from 40hp. The most effective ...

Back filling with confidence The best tool to fill trenches with gravel and/or sand. The Sand Unit even fills trenches from 40mm width with well consolidated sand, even when moist. Suitable for tractors from 40hp. The most effective ...

Low Noise Emissions The ZEL feeder gently processes screws, nuts, and pins while being easy on the material. The system supports cycle rates as low as 0.8 seconds. A low-vibration outlet rail minimizes vibrations, making it suitable ...

Abrasion-Resistant Surfaces The bowl feeder ZEB is designed for sorting, buffering, and transporting various small parts and fasteners. Screws, nuts, pins, washers, caps, and special elements are fed smoothly from the hopper to the ...

The SLD 4100 double gripper module gathers two single wires with outer diameters from 1 - 4 mm (0.039 - 0.157”) in the proper orientation allowing the swivel arm gripper to collect them. The wires are then moved to a separate station ...

Schleuniger

The PreFeeder 1100 is a solid and reliable benchtop, electric prefeeding machine for cable reels up to 20 kg (44.4 lbs.) and 457 mm (18") in diameter. This low-cost unit is ideal for feeding wires and cables off small to medium sized spools.

Schleuniger

The PreFeeder 2200 is a free-standing, electrical prefeeding machine designed to pull wire and cable from reels weighing up to 70 kg (154 lbs.).

Schleuniger

Specifications: Part size: max. 50 x 50 x 50 mm Part weight: max. 80g / part Bunker volume: 10 – 50 litres (depending on parts) Feeding speed: max. 30 m/min. (depending on part geometries)

Specifications: Stroke rate: max. 1,200 strokes/min (20 mm feed pitch) Feeding speed: max. 3.2 m/s Feeding force: 1,000 N Feeding accuracy: ± 0.02 mm Hydraulic clamping pressure: 3,000 N – 7,000 N Transport temperature: ...

The bulk product in the truck is discharged into the bunker and the process line is fed regularly. Length: 6 meters (at an angle to the ground) * Belt Width: 245cm. * Side Sheet panels open mouth Width: 320cm. Made of steel, painted. A ...

TABANLI MAKINA SAN VE TIC LTD STI

It is intended for receiving of raw materials to discharge from trucks and uniform feeding of the processing line. It is usable for many types of vegetables such as corn, green bean, green peas, spinach, broccoli, pepper etc. Uniform ...

TABANLI MAKINA SAN VE TIC LTD STI

RECEPTION HOPPER / FEEDING BUNKER for root vegetables such as carrot and potato. Body Length: 3,8meter x Width: approx. 2,3meter. horizontal or inclined up to 6° angle PVC Belt Conveyor Width: approx. 60cm. * Length: 3,5meter The height ...

TABANLI MAKINA SAN VE TIC LTD STI

G.P.A. pneumatic feeders, as all G.P.A. pneumatic equipments, completely match all the technical requirements of the EEC standards to day in force, particularly the "machinery" directive and the EMC directive, in some versions also for ...

G.P.A. ITALIANA

In bulk material handling, vibratory feeders are used to convey material from one piece of equipment to the next for feeding, sorting and sifting materials evenly and continuously into belt conveyor, bucket elevator, screening and crushing ...

Your suggestions for improvement:

Subscribe to our newsletter

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining