- Machine-tools >

- Machine Tool Accessory >

- Machine feed

Machine feed

In bulk material handling, vibratory feeders are used to convey material from one piece of equipment to the next for feeding, sorting and sifting materials evenly and continuously into belt conveyor, bucket elevator, screening and crushing ...

Two motors for feeding and vibrating separately; Fast installation, convenient maintenance; Easy cleaning, long time in use.

Air-Tec System: Customised solutions for your needs. We manufacture hoppers designed to specific requirements, ensuring that every detail is thought out and executed with care. Our hoppers are equipped with a wide range of customised ...

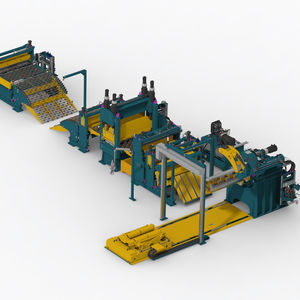

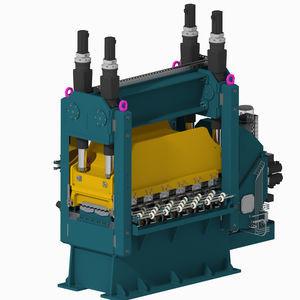

high-strength steel press feeding line

PRESS FEEDING LINE WITH TRANSFER BARS Key Features: Modular Design: Adaptable to presses of various sizes and capacities. Transfer Bars: Ensure smooth and secure movement of parts between stations. Precision and Reliability: Synchronized ...

Uncoiler: No foundations required, rails secured with chemical anchors. Capacity: Coils up to 16 tons (expandable upon request), width ranging from 250 to 1600 mm. SIEMENS motorization with brake energy recovery for operational cost ...

The leveler ensures consistent and reliable flattening quality, meeting industrial requirements. It is designed to process metal sheets efficiently while minimizing maintenance needs. Equipped with a semi-automatic cleaning system, it ...

New or existing presses or press lines can be expanded by blank feeding systems to achieve flexible forming processes. Depending on the requirement, feeding of contoured blanks can be guaranteed in the transfer mode. This system can be ...

For existing blank feed systems with conveyors, blank shuttles produced by H&T ProduktionsTechnologie make it possible not only to achieve higher feeding rates but also to enable transport in the correct order and optimal lubrication ...

Capacity: 100 m³

Preparation processes always have a beginning. After delivery, many facilities initiate the material input for processing. If errors occur at this initial stage, the subsequent process can never run optimally. Therefore, good metering ...

Suitable Screw Size:M2-M24 Step Feeder Mechanism Manufacturers Danikor is designed for feeding long bolts and screws.The Step Feeder Mechanism has four available models that meet various feeding needs, including screw air blowing type ...

Wuxi Danikor Automation Technology Co.,Ltd

Suitable Screw Size:M0.5-M2 The Danikor Disc Screw Feeder is an exceptionally reliable machine. It uses a rotating disk to position one fastener at a time in a precise location for easy retrieval. Fasteners can be picked up using either ...

Wuxi Danikor Automation Technology Co.,Ltd

Capacity: 5, 10, 20 l

● High cost performance - Large capacity and good quality stability. ● More stable - Independent R&D of straight vibration system, more stable vibration, more stable feeding. ● Safe and energy-saving - 24V/36V electronic control ...

Wuxi Danikor Automation Technology Co.,Ltd

E-FEED PM1 Manual Powder Management Center PM1 series equipment is suitable for semi-automatic applications. Fast cleaning. The lean design lets you utilise the production floor space. Smooth and effective powder distribution. Brilliant ...

ELECTRON

MANUAL POWDER MANAGEMENT CENTER Lean Solution for Basic Powder Coating Management PM1 Series paint centers are designed for applications where manual color changing is sufficient. Thanks to its simple design, it is user-friendly and ...

ELECTRON

SEMI-AUTOMATIC POWDER MANAGEMENT CENTER Fast Color Change Meets Lean Use PM2 Series paint centers are designed for applications where semi-automatic color change is needed. They provide fast cleaning as well as effective and homogeneous ...

ELECTRON

Capacity: 6 m³

An infeed hopper is placed in front of a processing line, to assure a uniform and continuous flow of products. The products can be brought into the hopper through a crate turner or wheel loader.

Herbort

Capacity: 8 m³

An infeed hopper is placed in front of a processing line, to assure a uniform and continuous flow of products. The products can be brought into the hopper through a crate turner or wheel loader.

Herbort

Capacity: 12 m³

An infeed hopper is placed in front of a processing line, to assure a uniform and continuous flow of products. The products can be brought into the hopper through a crate turner or wheel loader.

Herbort

• We build our feeders in robust stainless steel • We use a grinding mill • We offer hopper volumes between 20 to 300 cbm • We can batch according to time or weight • Our controller is interactive and self-monitoring • The feeder ...

Easy linen feeding Easy of use The “IFE” series feeder facilitates and speeds up the manual operation of inserting the linen. It can be used both for small items (pillowcases and napkins) and for medium items (table overlays and ...

PUSHER AUTOPOS motorized feeder to for aluminum saws for heavy loads. Available in dimensions of 3.4, 6, 8 and 10 meters Available in other dimensions on request roller length 350mm Useful cutting size ...

The hoppers of depositors are automatically fed by means of suitable Lifter and tiltersof Planetary mixer or Twin twist mixer bowl. On the limited volume hoppers of Depositor is recommended to fit a roller over-hopper to increase the ...

The CentriFeeder line of feeders provides accurate, real-time flow measurement, as well as near perfect control of flow rate and total. For blending applications, control the flow rate of an individual ingredient, or combine several CentriFeeders ...

The CentriFeeder with Integrated Control Valve, or ICV, accurately measures and controls the flow of any dry, free‐flowing solid. Using a highly customizable touch screen HMI integrated with a low rpm, AC, Brushless Servo, a PID control ...

The CentriFeeder line of feeders provides accurate, real-time flow measurement, as well as near perfect control of flow rate and total. For blending applications, control the flow rate of an individual ingredient, or combine several CentriFeeders ...

Capacity: 575 l

BULK HOPPER - BH Bulk Hopper for standard dough divider SD180/300/600. Creates an even level in the divider/sheeter hopper which gives better weight accuracy.. Features Photocell controlled closing/portioning system. Gives automatic ...

Glimek

Hopper elevators Food grade hopper elevators enables easy and hygienic product conveying to the demanded process. Hopper elevator is widely used for various processing solutions to lift the product to specific height and use gravity ...

PERUZA limited liability company

① The connecting rod mechanism and guide wheel are used to realize the reciprocating motion of the fixed action track and the lifting and overturning action of the turnover box. When the upper guide turns to the top, it automatically ...

COLUMN SELF-POWERED DRIVING STATION - tilting drawer screws positioning Max stroke - mm - 40 Length - mm - 595 Width - mm - 320 Height - mm - 1130 Base support - mm - 280 X 215 Weight - Kg - 35

SCREW FEEDERS - from bench with vibrating screws positioning

SCREW FEEDERS - from bench with tilting drawer screws positioning

The OMPSA electronic feeders, developed since the half of the Eighties with specific experience on this field, are particularly suggested for that kind of workings that use dies of progressive working kind requiring high speed production, ...

Our mechanical feed units of the M series, which are produced in the M100 and M200 models, are especially suitable for the feeding procedure of bands for high-speed mechanical presses, as long as they are equipped with a passing eccentric ...

chemical product feeding unitZRU

1.Compact structure, small size, good sealing capability, low leakage. 2.High Rotary Speed(Max 60rpm) . 3.Specific technology of avoid blocking for conveying material at high rotary speed can guarantee steady operation. Specification: Operation ...

Weight range: 7,500 lb - 400,000 lb

The Cardinal HBC hydraulic tank/hopper scale systems are designed to keep weighing accurately even in the harshest conditions and are the most reliable tank and hopper scales on the market. No power is required within the scale itself, ...

Simplify your stock control by labelling and coding your cases off-line! The TR-1000 Casefeeder is designed to feed flat, unerected corrugated cases for coding with inkjet, labelling, or print & apply. The case is presented to the inkjet ...

ERGA infeed hoppers are used as part of complexes for sorting, conveying or dosing lumpy, powdery, granular materials, as well as part of ERGA process lines. Bespoke design The volume and configuration of the hopper are selected considering ...

ERGA vibrating feeders are used for bulk and lumpy material discharge from hoppers or uniform and dosed feeding to components of processing plants and lines. - Wide range of designs and applications: ERGA vibrating feeders can have ...

Your suggestions for improvement:

Subscribe to our newsletter

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining