- Production Machines >

- Plastics Processing >

- Other plastic and rubber transformation machines

Other plastic and rubber transformation machines

The structural shell of Xaloy bimetallic barrels consists of a microalloy steel that maintains high strength and straightness after casting of the wear-resistant alloy lining. Unlike some barrel manufacturers, Xaloy can produce long barrels ...

Nordson Xaloy

common steel Conventional materials: 38CrMoAIA SKD61 Cr12MoV SACM645 Ni - GHII3 Nitriding hardness: HV900-1000 Nitriding depth: 0.5 0.8mm Quenching hardness: HRC55° - 62° Nitriding embrittlement: 950HV Thickness of chromium plating ...

Increasing the variety of raw materials used in plastic injection products, meeting the requirements for high pressure and higher speed printing, preserving the advantages of injection technology and eliminating the disadvantages that ...

This vulcanizer distinguishes itself for its strong structure in steel, mounted on columns also in steel of adeguate diameter; additionally, the generous sizes of the heating plates (Ø mm. 200) and the large diameter of the pressing screw, ...

Novagum S.r.l.

Pfactor deals with engineering and construction of injection moulds for thermoplastic materials, die-casting of aluminum alloys, Zama-alloy and structural polyurethane. We build equipments and moulds for various merchandising sectors, ...

fully automatic refrigerated cabinet foaming fixture. Some features of the mask: 1. - Mouth up technology. 2. - Automatic cabinet loading in the fixture. 3. - Side wall movement system with servomotor. 4. - Fixture walls and foaming ...

SAIP Advanced Polyurethane Equipment

AMZ stands for automated material loading. AMZ enables automated loading of metal bars into our punching machines. Different materials types (thickness/width) can be processed successively. This only requires a short manual intervention ...

low pressure foaming machine is my company tracking international high-end technology products, with the phenolic heat preservation industry application independent innovation and development of a high technology products. The Lord shut ...

For the production of flat-foil we offer a calander and polishing unit with following standard features: Vertical and inclined 3-roller-polishing system Single drive for each roller “swimming smoothing” for reduction ...

Product Description Details: - The cryogenic deflashing machine is a compact time-saving and quality enhancing cryogenic deflashing machine specifically designed to meet the most exacting demands of the rubber, plastics and metal ...

From the beginning, LED was involved in solving production and maintenance problems for polyurethane converters. To best reduce and eliminate these limits to productivity, and in response to our customers’ express requests, we developed ...

Ground rail circulating box foaming line

The new evolution of G-30H hydraulic proportioning unit fulfills even the most demanding requirements of industrial foam in place applications of two component systems. These component systems require high dosing precision to assure the ...

GAMA

The HPE serie, model can mount either a 150 or 250 liter tank and can be configured in different ways: depending on the capacity and type of pumps, you can choose amongst the HPE G (with gear pumps) or HPE P models (with piston pumps); ...

Europoliuretani Srl

The ViscoTreat-Inline represents a material processing system for a consistent and reliable product supply of low to high viscous fluid types. The system provides a sophisticated inline degassing process which allows the simultaneous process ...

Whether working with polyurethanes, epoxy resins, silicones, greases or other fluids, it is often necessary to prepare the materials before processing. This is due to issues such as sedimentation, air bubbles or dissolved air in the material. ...

1.One-Touch Operation 2.Work in Safety 3.Hydraulic Plus Electric Hybrid Control 4.Quick Die Clamping System 5.Size can be Customized Why Die Spiltter In the process of mold making, the separation of the mold is indispensable. ...

SXKH GLOBAL

This is a multifunctional Mold& die splitter and inspection equipment. Mold can be open and close by using this machine, and two mold can be tilted by 90 degrees as well and do mold maintenance on the machine. SXKH Mold Inspection Machine ...

SXKH GLOBAL

1.One-Touch Operation 2.Work in Safety 3.Hydraulic Plus Electric Hybrid Control 4.Quick Die Clamping System 5.Size can be Customized Why Die Spiltter In the process of mold making, the separation of the mold is indispensable. ...

SXKH GLOBAL

Rubber flat vulcanizer Rotorless vulcanizer is mainly used to measure the characteristics of unvulcanized rubber, find out the suitable vulcanization time of the rubber, and provide reliable data for the production process. The industry ...

Dryers and vulcanizers for latex foam Vulcanization and drying processes in latex foam production factories have always been an expensive and challenging task. RF Systems has developed the first RF equipment that overcomes all the issues ...

Strip Feeding Foaming Machine Introduction of foam-injection in barrier strip profiles Step1: Extruded indoor and outdoor profiles respectively. Step2: Feeding the heat insulating strip into aluminum profile notch to make barrier ...

Stalam has developed specific Radio Frequency equipment to vulcanise natural latex and SBR foam either inside moulds (mattress cores and pillows) or as a continuous sheet (LPC). The traditional Dunlop vulcanisation process uses steam ...

Tubing、Sucker rod Reparation Line Reasonable structure Stable performance Easy maintenance Energy-efficiency Product details Our company is specialized in design、production、installation、debugging and service of tubing and sucker ...

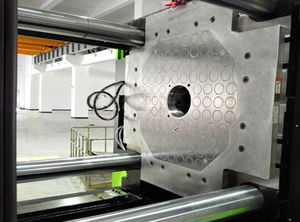

Easy to install on any injection molding machine without modifications of the Machine. Full metal clamping surface. Interface with the machine guarantees 100% safety. Reduces Mould setup time with -95% Generates extra production ...

With Laarmann Riffle Splitters you can divide products fast and easily. The Riffle Splitter comes with three buckets which can be used to drop and catch the sample from both sides. Sample Splitter Type RT 6.3 mm Sample Splitter Type ...

Mechanical screw type vulcanising equipment is conventional type and will be supplied on request.

Thejo Engineering Ltd

Your suggestions for improvement:

Subscribe to our newsletter

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining