- Industrial machines and equipment >

- Surface Treatment >

- Other surface treatment processes

Other surface treatment processes

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

CLIN treatments offer high wear resistance (abrasive and adhesive), which can be combined with excellent corrosion resistance. These advantages open up numerous outlets in the automotive, construction equipment, household appliance, ...

HEF GROUPE

CLIN treatments offer high wear resistance (abrasive and adhesive), which can be combined with excellent corrosion resistance. These advantages open up numerous outlets in the automotive, construction equipment, household appliance, ...

HEF GROUPE

Zinc/tin alloy and metal deposits by mechanical means to protect ferrous alloy parts against corrosion. Characteristics: • Good regularity of the deposited thicknesses • No hydrogen embrittlement • Ductile deposits susceptible to ...

HEF GROUPE

Smoke Detectors parts-custom metal stamping parts •Material: Stainless Steel •Process: Stamping corrosion •Requirements: No Burrs, Scratches, Dents, Pits •Application: Smoke Detectors •Packing: Bulk Packing, Tray, Tape& ...

This product is a customized high-quality black zinc-plated metal bolt with excellent corrosion resistance and strong mechanical strength, ensuring stable performance in various complex environments.

CCMS produces lost wax cast steel and alloy steel and ductile iron and various forged parts, all of which are tested for the chemical composition of the material, tensile, yield and elongation tests. Our products include hydraulic cylinders, ...

Ningbo CCMS Industrial Co., Ltd.

CCMS produces lost wax cast steel and alloy steel and ductile iron and various forged parts, all of which are tested for the chemical composition of the material, tensile, yield and elongation tests. Our products include hydraulic cylinders, ...

Ningbo CCMS Industrial Co., Ltd.

CCMS produces lost wax cast steel and alloy steel and ductile iron and various forged parts, all of which are tested for the chemical composition of the material, tensile, yield and elongation tests. Our products include hydraulic cylinders, ...

Ningbo CCMS Industrial Co., Ltd.

The Datanit probe is used to accurately determine a nitriding and nitrocarburizing atmosphere. This economical and ecological probe considerably reduces gas consumption in kN regulation mode (nitriding potential control). Ensures ...

Boriding is a thermochemical surface hardening method which can be applied to a wide range of ferrous, non-ferrous and cermet materials. The process entails diffusion of boron atoms into the lattice of the parent metal and a hard interstitial ...

Bodycote

Surface treatment: an essential step in the production of mechanical parts On the strength of its expertise in machining , Figeac Aero has also branched out into the field of "surface treatment" for the finishing of metal parts. In ...

Figeac Aero

Cars, door and cabinet hinges, fittings for computers and cell phones, water valves and shower nozzles, and so much more. Zinc die casting is an important reason zinc plays such a key role in many areas of our lives. Sometimes you can ...

Compression springs operate generally via pushing motion. Compression spring bodies are generally cylindrical, conical or bi-conical in shape. Available in all sizes and grades of 0.1 to 8 mm wire thickness, Filame manufactures according ...

Filame

KERBIRIO

Consistently high, uniform quality standards are required in many areas of industry. Electroplated surfaces are in use nearly everywhere and represent a reliable corrosion protection system. However: worldwide there are many companies ...

Your concerns drive our daily work. HACER is at your service and available to work together and develop your projects. A sustained rate of investment in our equipment and a constant technological watch enable us to monitor technical ...

HACER TRAITEMENTS DES METAUX

ETCHING PROCESS Chemical Etching is a technique used to engrave metals in an extremely accurate manner. It consists of a chemical engraving in which the corrosive action of an acid is used to etch the desired area. The metal sheet ...

FOTOMECCANICA SRL

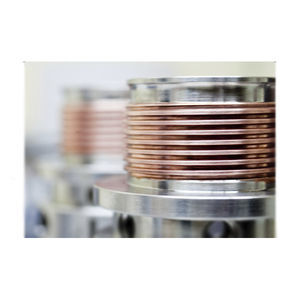

Copper Plating is electrolytic plating that deposits a layer of copper onto the substrate. This process is typically used to provide an anti-seize surface, as a mask to prevent carburizing on surfaces during heat treating, and to enhance ...

Pioneer Metal Finishing

THERMI-LYON GROUPE

Ion nitriding Ion nitriding takes place thanks to the diffusion of nitrogen and carbon on the material. In this way, layers are created that improve wear resistance, surface hardness and resistance to fatigue.

GSI Ingranaggi Srl

In close collaboration with our customers, over the years we have developed innovative solutions for photo chemical etching of sheets and thus have pushed the limits of what is technologically possible. The photo chemical etching process ...

Mekoprint A/S

Ramtech has developed a RAM cathode for use in four face target sputtering method, which enables the deposition of high-quality thin film. The RAM cathode features low damage, low temperature deposition, and a smooth surface with few ...

Keihin Ramtech Co.,Ltd.

1.Material:different kinds of stainless steel, iron,brass or aluminum etc. 2. Machining outside diameter:φ2.5mm ~ 240mm 3. Tolerance: +/-0.004mm 4. Machining length:1200mm 5. All kinds of surface treatments available: Polishing, ...

NANKAI

Experienced companies that are closely associated with Glüpker Blechtechnologie and share our philosophy carry out industrial coating using different processes. Thanks to the great flexibility and quality of the individual procedures, ...

Glüpker Blechtechnologie GmbH

Zinc protects more precious metals from corrosion and as such is indispensable in many industries. Galvanic zinc is deposited using acidic or alkaline electrolytes. The gloss level of the surface can be adjusted from matt to glossy by ...

Collini Holding AG

We also specialise in washing and degreasing. We offer them as a separate activity, but of course they can also be part of a larger order. We use special PERO equipment to wash the mouldings. We use several SUMMA washers for washing ...

Heat treatment We can perform a variety of heat treatments on products. This includes: • Solution treatment • QT(Quenching and tempering) • Quenching • Normalizing • Annealing • Precipitation Harding • Carburization • Nitriding • ...

Widely used in Electricity facilities Finishing: Tin plating

When it comes to professional industrial cleaning on location, Multinal Group is the right place. Industrial cleaning includes chemical technical cleaning of pipelines, tanks, heat exchangers, process installations, production units, ...

Copper plating is one of our basic plating processes that has been the core of our business for many years. As a result, we have accumulated a wealth of knowledge in producing high-quality Copper-plated goods of various process classifications. ...

Applied Total Control Treatment Pte Ltd

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining