- Production Machines >

- Other Manufacturing Equipment >

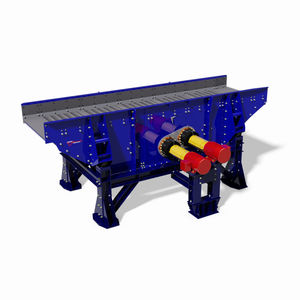

- 2-motor screener

2-motor screeners

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Weight: 75 kg - 510 kg

Opening of the mesh: min 0.5 mm

Screening surface: 0.2 m² - 2.6 m²

... the Vibration Screening Machine Vibrall is particularly suitable for use in vertical conveyor systems with high conveying capacities. Functionality: The drive of the Vibration Screening Machine ...

Capacity: 6 t/h

Engine power: 4 kW

... product remains and the fines are screened off. All three fractions are discharged via separate outlets. Two unbalance motors generate the necessary vibration, while the mechanically adjustable screen inclination ...

Weight: 19,000, 17,500, 15,000 kg

Screening surface: 14.4, 12, 10 m²

Engine power: 30 kW

... eccentric weights are connected to each other via the propeller shaft. There is 2 special screen roller in each bearing group. There are 2 bearings group smaller than 14 m2 and 4 bearings ...

Weight: 30,000, 34,000 kg

Screening surface: 16.3, 20 m²

Engine power: 30, 44 kW

General Machine top driven stage screens are made in 3 stages. The slope of the rear stages of material flow rate is too high. Though this high-speed all material would have the opportunity to contact with mesh screen. ...

Weight: 1,500 kg - 11,000 kg

Screening surface: 3.6, 3, 2.4, 4.9, 6.4 m²

Engine power: 10.2, 11.5, 7.5, 15 kW

... of the secondary crusher. G type grill screens are driven with 2 vibrators and made linear vibration. M Type grill screens are driven as in conventional screenswith a separate electric ...

Weight: 132 kg

Opening of the mesh: 20 mm

Screening surface: 0.3 m²

The KTS-VP2 control screener is suitable for inline use in all types of pneumatic conveying, one in particular being the truck unloading into silos. Adding this to the system guarantees optimum product ...

dry screening screenerMSizer

... consisting of 2 to 6 stacked screen decks with varying inclinations and decreasing mesh sizes downwards. The easily maintainable screen panels are cleverly placed in a compact housing and are set into precise vibrations ...

Screening surface: 0.5 m² - 1.2 m²

Industrial safety sieves protects industrial facilities from contamination and damage. For example; the unit transferred from a sack to the sieve to prevent food contamination. Large particles are trapped by the safety sieve and are not ...

... High G force operation. Pretensioned shale shaker screen for fast screen replacement Famous Brand Vibration Motors : IEC Ex, ATEX and UL Certified Electrical components: SIEMENS, Schneider ...

General Kinematics V2™ Variable Angle Shakeouts allow you to adjust casting retention time with the push of a button. Long lasting components and extra heavy-duty construction offer extended uptime and low maintenance ...

General Kinematics

Weight: 15,000 kg - 18,500 kg

Engine power: 60 kW - 90 kW

... difficult maintenance equipment such as the gear system. DRIVE SYSTEM In order to create a high energy elliptical movement, the two drive systems rotate in the opposite direction. Each drive ...

DESCRIPTION The direct discharge vibrating screens with two side motors are used to carry out “in line” control sieving, thanks to the central feeding system aligned with the discharge hopper, below the screened product. ...

... sieve pore is large than required for sieving granularity in accordance with the using of probability theory, and it is 1.2-2.2 times than required granularity usually, greatly improving ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining