- Machine-tools >

- Machining Center >

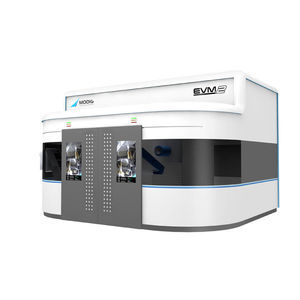

- 50 tools machining center

50 tools machining centers

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

X travel: 1,626 mm

Y travel: 1,270 mm

Z travel: 1,016 mm

... HMCs offer large work cubes and a maximum part capacity of 10,000 lb, making them perfect solutions for your large-part machining requirements. The EC-1600ZT-5AX has a 4th-axis rotary platter integrated into the ...

Haas Automation

X travel: 1,626 mm

Y travel: 1,016 mm

Z travel: 1,067 mm

... angle on the part for complex shapes, undercuts, and 5-side machining. Dual-axis spindle head provides ±245 degrees of C-axis rotation and ±120 degrees of B-axis tilt Includes Tool Center ...

Haas Automation

X travel: 2,134 mm

Y travel: 1,016 mm

Z travel: 1,067 mm

... angle on the part for complex shapes, undercuts, and 5-side machining. Dual-axis spindle head provides ±245 degrees of C-axis rotation and ±120 degrees of B-axis tilt Includes Tool Center ...

Haas Automation

X travel: 350 mm

Y travel: 500 mm

Z travel: 320 mm

... FEHLMANN VERSA 645 linear allows for machining workpieces highly dynamically in five axes and with maximum precision. Thanks to the intelligently designed drive concept compromises between precision and dynamic machining ...

X travel: 350 mm

Y travel: 500 mm

Z travel: 320 mm

... visibility into the machining area. Manual part loading is done from the front. The door extends right into the machine roof, allowing for comfortable crane loading from the top. The tool changer with ...

X travel: 600 mm

Y travel: 400 mm

Z travel: 610 mm

The PICOMAX 75 impresses with high precision, best rigidity and optimum energy efficiency. Tool magazine with loading from front during machining, a compact, space-saving design, as well as Fehlmann-typical, ...

X travel: 1,200 mm

Y travel: 1,300 mm

Z travel: 900 mm

Machining Centre C 62 The C 62 is a highly dynamic machining centre designed for 5-axis/5-side machining. Numerous features ensure high-precision and cost-effective working on workpieces ...

X travel: 4,250 mm

Y travel: 3,200 mm

Z travel: 800 mm

90°angle attachment tool for four face machining - standard equipment 5°indexing machining performed by EIA / ISO program) Column height 1650mm (64.96") by utilizing cross rail with ...

X travel: 1,020 mm

Y travel: 700 mm

Z travel: 500 mm

... 1.050 x 700 T-Slots (DIN 650) - 6 x 18 H8 x 125 SPINDLE Spindle Torque max. (Nm) - 119 AUTOMATIC TOOL CHANGER Tool diameter max. (mm) - 76 Tool length max. (mm) - 300 FURTHER ...

Hurco GmbH Werkzeugmaschinen

Rotational speed: 18,000, 20,000 rpm

Power: 20 kW

... airfoil, in 1 setup as well as probing and adaptive machining of welded blisks. Uncompromising for airfoils High-dynamic machining around the entire airfoil for better quality results and longer tool ...

X travel: 1,250, 2,100, 1,600 mm

Y travel: 800 mm

Z travel: 950 mm

... The tool magazines on a Sigma Flexi vertical machining center are structurally independent of machine movements. This enables tools on the chain to be easily and safely ...

X travel: 3,050 mm - 12,050 mm

Y travel: 2,600, 3,100, 3,600, 4,100 mm

Z travel: 800 mm

Our MCR-A5CII is a high-speed double column machining center with compact auto-loading/unloading attachments for true 5-sided machining in a compact footprint. The solid double column ...

OKUMA

X travel: 4,200, 12,200 mm

Y travel: 3,200, 4,200 mm

Z travel: 1,050, 1,250 mm

... provides efficient and accurate machining of large components. The MCR-C double column machining center’s auto tool changer (ATC) and full array of available spindle ...

OKUMA EUROPE GMBH

Table load capacity: 20, 100 kg

... build an automation system with up to 338 tools (matrix magazine) and up to 91 pallets (linear pallet system), while easily achieving high-variation/low-volume production and prolonged unmanned operation. The tool/pallet ...

MATSUURA

X travel: 1,400 mm

Y travel: 1,050 mm

Z travel: 600 mm

With QUADROGUIDE® for high roughing capacity, dynamics and precision All axes with direct drives Milling spindle may be chosen depending on the application, up to 101 Nm (S1) available Ideal for forging dies, mould ...

Roeders

X travel: 660 mm

Y travel: 1,020 mm

Z travel: 500 mm

... Standard Features -- 21-GB SSDR for program storage - 3-light indicator lamp - 33-rpm +30/-110° A-axis trunnion - 40-tool, swing-arm ATC - Coolant washdown system - Hand-scraped contact areas - Heidenhain ...

X travel: 2,500 mm

Y travel: 1,600 mm

Z travel: 800 mm

... profile parts. MODIG provide solutions to make your production more efficient. Your machining cycle time at the process design stage: up to 50% faster machining time over conventional ...

X travel: 16,000 mm

Y travel: 4,600 mm

Z travel: 1,400 mm

... built for heavy-duty machining. •In addition to the machine itself, JOHNFORD also designs and makes all types of milling heads, ranging from a simple 90° milling head to an electro 2-axis ...

X travel: 120 mm

Y travel: 130 mm

Z travel: 150 mm

The ROTOPAL 200 is a high precision machining and micromachining machine with 4 axis. It’s mainly dedicated to the machining of high-value, complex or high precision parts. With ROTOPAL 200, you are guaranteed ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining