Air coolers

... cooling chambers and/or quenching tanks are available. A forced air cooling station with exhaust hood can be integrated in the line and fed by an automatic loading machine. Internal air recirculation ...

Power: 5 kW - 180 kW

Maximum temperature: 7 °C - 35 °C

Flow rate: 3.6 m³/h - 33 m³/h

CE Certificated Description Benefits & Features •Controlled by PID micro computer, accurate temperature control. •Pump overload protection to ensure service life effectively. • Alarm device for low liquid level to guarantee ...

... Answering to the many industrial needs, SIMACO - leader in the fluid moving technology - designed a dedicated range of close loop air-water cooling units, where the SIMACO pump, actual beating heart, is naturally assembled. This ...

- Inlet Air Cooling System for GT system - Semi Dry-Fog®, a fine fog with a mean droplet size of 10-30 μm, cools gas turbine intake air and improves power generation output during hot ...

The powerful DC fan can forcibly remove heat accumulated in the mixer system. · Reduces mixer system temperature by approximately 10 degrees. · Suppresses mixer system temperature increase due to heat generated by material. · Realizes ...

Power: 93.2 W

Motor - 1/8HP (The motor of cooling system could be upgrade.) Size - 440x220x460mm

... production line management flexibility. • AISI 304 stainless steel machine • Plastic conveyor belt • Forced ventilation system for internal hot-air circulation • Insulated and enclosed holding cabinet ...

Power: 700 W

The new Air Cooler replaces the traditional expensive water cooler used with the CAL3K range of calorimeters. It uses less resources, including no water and less electricity, to operate. ...

Coolant chillers are essential to your machining operation. Metalworking fluids must be maintained at a constant and correct temperature for your application to ensure you produce consistent high-quality parts. Quality ...

Cooling systems are precisely matched to the system configuration. Each cooling system consists of internal and external cooling. Cooling ring (external cooling) Base body fully thermally insulated ...

Maximum temperature: -40 °C - 350 °C

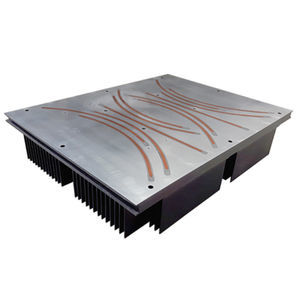

The Fabfin heat sink stands out from ordinary extruded heat sinks because of its increased surface area, giving it excellent performance. Using a swaging process means a variety of its higher fins and increased height-to-space ratio types ...

Power: 0 kW - 303 kW

Maximum temperature: 121 °C

Flow rate: 0 l/min - 999.2 l/min

... industrial air oil coolers offer a compact and durable design that will provide efficient performance and long life. They provide up to 400hp of cooling and are suitable for most applications and environments. Parker's ...

Parker Electronic Controls Division

Pressure: 6 bar

... patented liquid cooler for cool down of shrink-fit chucks. Fast, contour-independent cooling, cleaning and rust protection. The housing of the FKS 04 S is filled with cooling water. The water is lifted into the tower ...

Maximum temperature: 0 °C - 40 °C

Pressure: 2 bar - 7 bar

Cold air generator at most 60°C lower than the intake air only by blowing compressed air (Vortex principle). Used for cooling in many applications.

AUTOMAX

... using ambient air, but tempered air or conditioned process air can also be used for special applications. Depending on the application, coolers can be divided into different ...

1.The Industrial Chiller is mainly used to provide cooling water for high-end industrial equipment, at the same time, also widely used in mechanical processing and manufacturing,plastics and rubber,electrical and electronic, ...

Flow rate: 180 m³/h - 12,600 m³/h

Pressure: 12 bar - 16 bar

... cooling of compressed air: Water-cooled compressed air aftercoolers of the HWO-A series from FST are an extremely efficient way to cool compressed air. This enables ...

Power: 26.7 kW - 104.7 kW

Flow rate: 7,500 m³/h - 26,000 m³/h

The MatrixAir™ precision cooling system has been developed to meet the increasing demand for ultra-efficient and large capacity. It is a room-based cooling system that can deliver efficient, precise, ...

Shenzhen KSTAR Science and Technology Development Co. Ltd

Pressure: 70 psi - 115 psi

... tool-work interface. Expanded compressed air cools tooling and helps remove chips from the cutting interface. The mist coolant lubricates flutes, holes and chips to improve hole quality. The system ...

The machine tools used in production processes require a reliable and precise temperature control. The cooling of the mechanical components and the cutting and hydraulic fluids allow the machine tools to work at high speeds, in an accurate ...

Power: 800 W

... cooled by water, allowing you to host up to 45 kW of equipment without heating the air on output, and without disrupting the ventilation of the servers. The heated air coming from ...

Power: 14,500 W - 144,000 W

Maximum temperature: 5 °C - 35 °C

Flow rate: 40 l/min - 360 l/min

Air Chillers adopt fin condensers (without need for cooling water) with the features of rapid heat transmission and excellent heat dispersion. This series can be afforded cooling ranges from 5~35℃, even ...

... distortion or "checking." • The cooling conveyor is constructed in a modular fashion to allow for installation in various widths and sizes. • Fresh air intakes on the top of the cooling chamber provide ...

Automatic pouring and cooling lines with the possibility of tracking software to control the cooling time.

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining