- Industrial machines and equipment >

- Furnace and Heat Treatments >

- Air dryer

Air dryers

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

... expenditure (for both air circulation and water evaporation) which means economic drying, protects the environment and saves money. The air circulation technique Economic central fans at the end ...

... Application: ALM-CCDA dryers provide clean air directly at the point of use. Sensitive measuring instruments Dental air Medical air Food packaging ...

ALMIG Kompressoren GmbH

... and oil-free air directly at the point of use. Sensitive instruments Dental air Medical air Food packaging Prefiltration for gas separation membranes Breathing ...

ALMIG Kompressoren GmbH

... adsorption dryers are used where compressed air has to be dried to a pressure dew point of -20°C, -40°C or optionally -70°C. The series offer compact design and simple operation. ALMiG ...

ALMIG Kompressoren GmbH

... parameters, such as temperature, Dew point and flow rate of the process air, according to the production detected. A flow meter, located in the air supply line, controls the air flow ...

Piovan

... desiccant dryers available. Design Features Low Profile Design Low Mounted Filtration for Ease of Service NEMA 4-Standard 7” Color Touchscreen Controller Tower Pressure Gauges Packaged Filtration — Standard Benefits ...

GD Compressors

... with preventative air treatment. Our SD membrane dryers ensure the highest compressed air quality Optimal safety and efficiency Atlas Copco’s SD membrane dryers ...

ATLAS Copco Compressors USA

... These compact inline desiccant dryers are a convenient and cost effective means of ensuring your sensitive intermittent pneumatic applications are not exposed to damaging moisture. As wet air ...

... improved to make these dryers smarter, more intuitive, and easier to learn and use. This makes the Carousel Plus dryer perfect for existing or new operators. Designed to work seamlessly with Conair’s ...

... perforated filter belt, through which the air passes as the belt is conveyed through the drying and cooling zones. This method helps to minimize the risk of lumping, smearing or deposit formation in the dryer, ...

GEA Wiegand

... solution for optimal results Features Straight tube air distributor (STAD) with integrated high-pressure nozzle assembly • Single or multi venturi air distributor evenly distributes drying air ...

... kiln +burners. ◆ Saving investment, easy operation and maintenance. ◆ The dryer is composed of several modules, each module is an independent drying unit with 1 recycling air fan, 1 or several humidity ...

... shelves with holes, access door with two doors with grip gaskets. Filter ventilator for the input air and centrifuge aspirator. Electric heating with air heating. Temperature range from +5°C over room ...

... synthetic granulates. The dryers are mounted on the funnel of an injection moulding machine, it is to take care that the collar of the air exit tube is covering the material entering fitting. The warm ...

... today's economic conditions, STENTEX reaches higly satisfactory production capacities by means of new developed nozzles and air circulation system, The newly developed STENTEX is a high performance drying and heat-treament ...

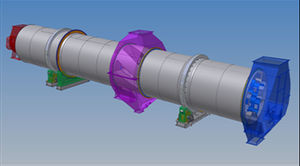

... Fletcher monotube dryer-cooler dries and cools the sugar. Simple and efficient technology Cail & Fletcher monotube dryer-cooler comprises a rotary cylinder mounted on path rings and trunnions. Vacuum ...

... m. long chambers with crossed arrangement Heating by gas, thermal oil, steam and electricity DUAL FLOW air circulation system PATENTED FPE air flow equalizing system Airflow bypass at any machine ...

UNITECH TEXTILE MACHINERY

... fluid bed The air distribution systems send constant air flow at controlled temperature and volume into the spray dryer, integrated fluid bed, and optional external fluid bed. The ...

Anhydro

... Desiccant Air Dryers • Reduces air loss. Conventional desiccant dryers use dried air during regeneration and compressed air causes ...

... therefore allowing significant energy saving over time. Ventilation system: The main function of the ventilation system is based on the continuous circulation of air. During ...

... molecules from compressed air and nitrogen. Only water molecules permeate through the hollow fiber membrane and they are exhausted outside. Oxygen and nitrogen pass through the hollow fiber and come out as dry air. it ...

... precise temperature control, and high degree of intelligence. The double-drum dryer is developed to completely replace the drying bed and partially replace the mesh belt dryer. Due to the realization ...

YOKISTAR waterborne paint drying system is designed to speed up the drying time of the water base paint. You are expected to use this system in both spraying and baking status.While in spraying, it can accelerate the ...

Volume: 4.5, 10.2, 6.8, 20.4, 13.6 m³

... The STN-C-SK dryer can, upon request, be equipped with a double alternating air flow system (model STN-DF): this exclusive system increases drying uniformity, improving product quality and optimizing ...

... technology for R&D, pilot, or production applications, Fluid Air is the answer for more viable end products that perform. Fluid Air fluid beds are recognized in the industry as a leader in air-moving ...

We’ve built a reputation on being the best rotary dryer manufacturer in the industry. All of our dryers are custom designed to suit the unique processing needs of your material. Whether you require low- ...

Compressed air is always 100% saturated. When it cools, the moisture will condense, causing damage to the air system. Untreated air with excessive moisture can cause corrosion in pipes ...

Your suggestions for improvement:

An air dryer reduces the humidity in compressed air. This helps fight corrosion due to condensate in compressed air systems.

ApplicationsThese devices are found in a wide range of industrial domains including painting, tool and die making, chemicals, draining systems, automation, ozone generator feeds, medicine and respirators.

TechnologiesThe refrigeration dryer chills the compressed air to below its dew point (down to -20° C), causing the condensation of the water vapor in the air. The liquid water is removed by a separator.

The adsorption dryer has two columns operating in two cycles, drying and regeneration. The regeneration characteristics affect the dew point, which can be as low as -70° C.

The membrane dryer operates via permeation. The compressed air passes through hollow, porous fibers which allow only the water molecules to pas through. The dried air enters the distribution network. Dew point can be as low as -70 ° C. These models are suitable for low-volume air flow.

Choice will depend primarily on specific use. Other factors include ease of installation and maintenance, output and noise level. The dryer can sit on the floor or be mounted on a bench, wall or ceiling.

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining