- Production Machines >

- Other Manufacturing Equipment >

- Aluminum forging

Aluminum forging

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Our high-quality custom copper busbars are designed to meet your electrical conduction needs. Made from premium copper materials, they ensure excellent electrical conductivity and long-term durability. Each busbar is precision-machined ...

HLC METAL PARTS LTD

This Aluminum Plate is crafted from high-quality aluminum and finished with a clear anodized surface that enhances durability, corrosion resistance, and a sleek appearance. Designed with precision, it ...

HLC METAL PARTS LTD

Our bespoke metal sheets are made with cutting-edge stamping techniques and are intended to satisfy a broad spectrum of industry requirements. The product has great performance, high accuracy, and is ...

HLC METAL PARTS LTD

... Forged Parts - Solid and semi-solid parts - Sleeves / Hollow parts - Threaded parts - Knurled parts - Step pins - Ball pins - Metal plastic parts - Special parts

Matson Metal is a supplier of OEM valve castings with machining service in China. With 20 years' experiences in this industry, we focus on and have advantages in the following aspects: engineering - Review and evaluate ...

For the manufacture of metal parts, screws and rivets, ETMA has the capacity to work wires with a diameter between 1.5mm and 12mm in double blow and multi slide horizontal presses and in a variety of materials. We can ...

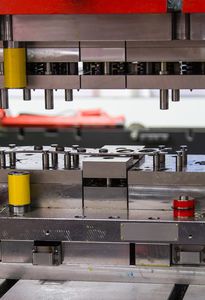

... only some of them. Stamping consists on compressing a specific metal between two moulds. There are two types of stamping: the progressive stamping and printing by percussion. In progressive ...

GESTION DE COMPRAS

Nous produisons des composants à partir de feuillard de largeur jusqu'à 600mm et d'épaisseur 0.5 - 4 mm. Presse mécaniques de 30 à 500 t

We manufacture parts by cold metal stamping and drawing, up to 160 tons, with all types of metals, steel, aluminum, stainless steel...

... scrap metal Increased repeatability Varied geometries for the parts Lower part costs With a pressing force of up to 50 tonnes and 950 bpm, the machine types for micro stamping / progressive die ...

... Stamping, Laser Cutting, Casting, Forging, Surface Treatment, and Assembly services. With excellent production capabilities, we meet diverse order requirements with flexibility. Choose from a wide range of materials like ...

... steel: S355JR, 1020, 1030, C45 • Alloy steel: 18CrNiMo7, 40Cr, 42CrMo • Stainless steel: SS316, SS304 • Aluminum alloy Process: • Open die forging + machining + • heat treatment Size: • Medium: ...

High Precision Aluminum Stainless Steel Bending Parts Assembling Metal Stamping Parts The stamping parts have high precision sizes and are consistent ...

Qingdao Yonglihao Machinery Co.,Ltd.

... operations – shearing, bending, drawing, threading, roll bending and pressing on eccentric and hydraulic presses with feeders or wire straightening. We have our own tool room for tool maintenance. MACHINE EQUIPMENT ...

OEM & ODM:Custom according to drawing or sample Available Materials:Steel,stainless steel,Brass,Aluminum Types: Custom,various type Surface Treatment: zinc/nickel/tin/chrome/brass/copper plated,black oxide coated,sandblast,powder ...

WE ARE FORMING METAL The challenges of our customers rise on a daily base. Therefore it's vitally important to coordinate ail aspects of the manufacturing technologies. Stamping, bending, clinching and threading are ...

... and fast, and we deliver by the deadline. Advantages of sheet metal stamping -from the economic aspect it is most advantageous method for mass production -progressive stamping ...

Stamping tools: Progressive Stamping Single Hit Stamping Transfer Stamping The thickness of the molded material is in the range of 0.5 – 2.0 mm. The material ...

Your suggestions for improvement:

the best suppliers

Subscribe to our newsletter

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining