- Production Machines >

- Machine for the electronics industry >

- Automatic rework station

Automatic rework stations

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

The Ersa Rework System HR 600/3P enables automatic repair of SMT components such as BGA and MLF up to edge lengths of 1 x 1 mm with precision and reliability. HRSoft 2´s graphical user interface enables ...

Ersa GmbH

We provide ""skill-less"" rework operations for a wide variety of rework processes. Three ""skill-less"" We use the latest technology to solve the issues we have faced in the past. 1. Automated ...

The Ersa Rework System HR 600/3P enables automatic repair of SMT components such as BGA and MLF up to edge lengths of 1 x 1 mm with precision and reliability. HRSoft 2´s graphical user interface enables ...

Kurtz GmbH & Co. KG

Description The Rework Station is mostly placed after an Automatic Optical Inspection System (AOI). It is equipped with three singlelane segments with a length of 530 mm each. The segments ...

1. Fine solder, bright and beautiful solder joints. 2. High soldering speed, small thermal deformation, only heating the surface of the reworked component, small impact on the periphery, preferred choice for the dense soldering. 3. ...

Quick Intelligent Equipment Company

... - Contactless and automatic removal of residual solder. • All axes are motorized with closed loop motion control. • Manual movement via integrated handwheels for fast and precise positioning of the hot gas head. ...

... this rework system is simple and intuitive. Efficient convection heating provides high thermal throughput, uniformity, and repeatable rework processes. Motorized X, Y, Z, and theta axis and Component ...

... world, which exert better effective heating than existent rework devices such as ceramic type heating machine. Hot Air for both Up and Lower heater is fast in instruction response with automatic temperature ...

REGEN-I Company

R7850A PCB smart optical BGA soldering station machine is an optical alignment automatic rework equipment. This BGA Soldering Machine has multi-functional control features, convenient ...

Shenzhen Zhuomao Technology Co., Ltd.

・All-IN-ONE Advanced Technology SMT Rework Station ・Compatible for all kind of rework for different type of SMT components ・Multi-functional profiles can be handled at will ・Wide support ...

DEN-ON INSTRUMENTS Co., Ltd.

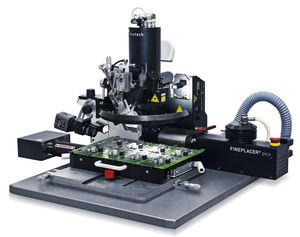

High Density Rework Station FINEPLACER® pico rs is an enhanced hot air rework station for assembly and rework of all types of SMD components. The ...

- Protection for plastic parts or PCB boards. Components like buzzers and IC sockets will not be easily burnt; PCBs will not bubble; - Air volume linearly adjustable. It remains stable even when supply voltage varies. ...

Madell Technology

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining