- Production Machines >

- Other Manufacturing Equipment >

- Ball mill

Ball mills

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Rotational speed: 3,000 rpm - 3,600 rpm

... Micro Mill PULVERISETTE 0 is the ideal laboratory mill for fine comminution of medium-hard, brittle, moist or temperature-sensitive samples – dry or in suspension – as well as for homogenising of emulsions ...

Rotational speed: 900 rpm - 3,000 rpm

... , fast, effective. WORKING PRINCIPLE Impact and friction The FRITSCH Mini-Mill PULVERISETTE 23 grinds the sample through impact and friction between grinding balls and the inside wall of the grinding ...

Final grain size: 5 µm

Motor power: 260 W

Machine length: 577 mm

... LN2 feeding systems, jar and ball sizes, adapter racks, materials low LN2-consumption clearly structured user interface, memory for 9 SOPs programmable cooling and grinding cycles (10 ...

Retsch GmbH

Rotational speed: 1,000 rpm - 1,500 rpm

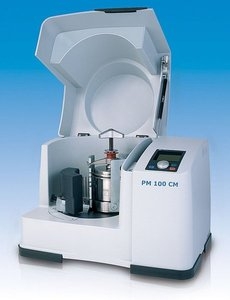

The XRD-Mill McCrone was specially developed for the preparation of samples for subsequent X-ray diffraction (XRD). The mill is used for applications in geology, chemistry, mineralogy and materials science, ...

Retsch GmbH

Rotational speed: 300 rpm - 2,000 rpm

... and impact which results in ultrafine particles after very short grinding times. The speed of 2,000 rpm is unmatched in a ball mill. The high energy input is effectively used for the grinding process ...

Retsch GmbH

... several available configurations depending on the application and mill size. NETZSCH Ecutec also carries an extensive selection of special grinding media to optimize the performance of the ball mill ...

The ZR/R bead mill series is designed for products with low to medium viscosity. In the process zone with rotating rotor and drum, differential peripheral speeds up to 21 m/s are possible. Variable overdrives ...

Output: 0 t/h - 11 t/h

... The ball mill adopts special design and suitable proportion of grinding medium to achieve ideal grinding fineness; The slab-type grinding tail discharges, the discharging is smooth, and the cylinder ...

... designed, manufactured, and installed more than 8,000 ball/pebble mills, all over the world. Both the ball and pebble mills utilize a tumbling media, ball ...

Rotational speed: 42 rpm - 69 rpm

... Rod / Ball Mills are Rubber coated and manufactured in Double and Triple Roll models. The Rolls are 120 mm diameter x 1200 mm long and powered by a 0.37 KW 220 Volt Motor with a variable speed controller. Ball/Rod ...

Final grain size: 74 µm - 400 µm

Rotational speed: 21 rpm

Output: 16 t/h - 50 t/h

Ball mill is suitable to grind various mineral and other materials, which is widely used in various industries such as benefication, construction materials, chemical industry, etc, it has two ore grinding ...

Final grain size: 74 µm - 400 µm

Rotational speed: 21 rpm

Output: 16 t/h - 50 t/h

Ball mill is common used grinding plant in the industry, and it is key equipment used for milling after materials are crushed. This machine can be can grind all kinds of ores and other materials, which ...

Final grain size: 74 µm - 400 µm

Rotational speed: 21 rpm

Output: 10 t/h - 20 t/h

Ball mill is common used grinding plant in the industry, and it is key equipment used for milling after materials are crushed. This machine can be can grind all kinds of ores and other materials, which ...

Final grain size: 20 µm - 22 µm

... Weight 400 kg The MILL25 Ball Mill Refiner is used to produce/refine nut paste (hazelnut, almond, pistachio, macadamia nut, etc.) for spreads, chocolate, chocolate substitutes and ...

Final grain size: 20 µm - 22 µm

... Weight 600 kg The MILL50 Ball Mill Refiner is used to produce/refine nut paste (hazelnut, almond, pistachio, macadamia nut, etc.) for spreads, chocolate, chocolate substitute and pastes ...

Output: 1 t/h - 200 t/h

... classifier. This type of separator is usually installed on Pendulum Roller mills but can be used in a pneumatic circuit, alone or combined with a Pulverizer or Ball mill ...

... frame for the drive unit. The drum and balls can be sterilized in water. For using the ball mill, a drive support is needed, which is optionally available in a lengthened version for ...

Final grain size: 200 µm

Rotational speed: 50 rpm - 3,000 rpm

Machine width: 270 mm

A compact benchtop grinding mill with powerful and shear crushing capabilities IQ MILL-2070 makes the sample grinding process into a simple pre-treatment operation. By using a special high elastic belt ...

Rotational speed: 23 rpm

Output: 0 t/h - 1 t/h

... fine milling results and larger ones for coarser milling tasks. The drive sets the milling drum into slow rotation and the bed of milling media is thus activated, ...

... AG milling extends itself to many applications due to the range of mill sizes available. AG mills can accomplish the same size reduction work as two or three stages of crushing and ...

Output: 8, 32, 50 t/h

... control and separation. The FAM product range includes impact mills, roller mills, hammer mills, ball mills and rod mills, as well ...

Rotational speed: 1,425, 1,725 rpm

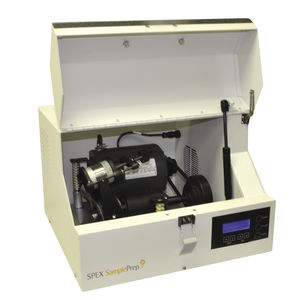

The High Energy Ball Mill (model: 8000M), manufactured by Horiba Scientific, is capable of accommodating samples sizes ranging from 0.2 up to 10g. In addition, this type of mill is best ...

... you get with our FT Series Grinding Mills. FT Series Mills can be used as ball mills, rod mills or pebble mills, in trunnion overflow, ...

... installation layout Customer benefits The lowest energy consumption: from 30% to 65% compared to ball mill, from 10% to 20% compared to vertical mill The best product quality ...

Fives

Output: 190, 800 t/h

Machine weight: 12 t

... Pneumatic extraction from the surface of the agitated media bed Wet grinding: Separation of suspension from the agitated media by ball retaining device Flexibility Through careful selection of the size and quantity ...

Maschinenfabrik Gustav Eirich GmbH & Co. KG

Output: 1 t/h - 90 t/h

Motor power: 19 kW

Machine weight: 4 t - 65 t

... The dry type and wet grate type mill can be selected according to the nature of materials and discharging mode. The ball mill manufactured by our company has three (3) types: wet grate, ...

• HIGH-PERFORMANCE VERY FINE GRINDING • Capacities up to 1.000 kg/hour* (Inline setup) • From lab to industrial scale Functions: • ultra fine grinding Main applications: • paints and varnishes • softgel fillings • lipstick ...

... extensive range of Bead Mill ( 1.4-150 litres ), which is fabricated using high grade raw material to ensure optimum quality in the end product. Our ZR splash mill assists in sending ...

WAHAL ENGINEERS

... ultra fine grinding beads below .1 mm in size Process times up to 6X faster than conventional mills Less media needed means reduced operating cost Requires minimal operator interface Patented auger optimizes ...

Rotational speed: 70 rpm - 80 rpm

● High operational reliability, stable performance, simple structure and easy maintenance. ● Model with speed controller available.(Model : J-BM1-S) ● Displays realtime operation speed utilizing rpm meter.(Model : J-BM1-S)

JISICO Co., Ltd.

Balls are placed in a rotating drum with the product. Products are ground thanks to the friction and the impact resulting from dropping the balls against the product and the collision between particles ...

Your suggestions for improvement:

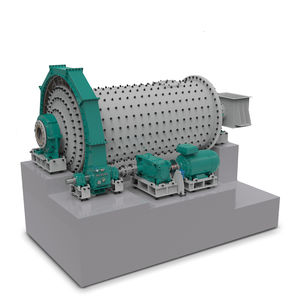

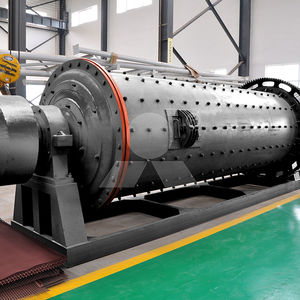

A ball mill crushes solids into a fine powder within a rotating drum, using balls as the grinding medium.

ApplicationsBall mills are found in settings as diverse as laboratories and mines, among others.

TechnologiesBall mills can grind in either a wet or a dry environment. In addition to the traditional rotating-drum type, some models use planetary, vibrational or centrifugal motion.

How to chooseChoice of ball mill will depend on the type and quantity of product to be ground.

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining