- Metrology - Laboratory >

- Inspection and Monitoring >

- Bar inspection system

Bar inspection systems

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

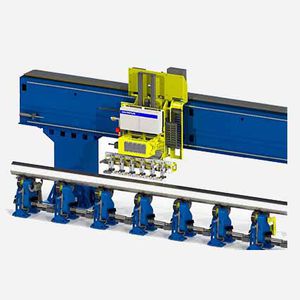

The bar inspection system (BIS) is a turnkey solution that uses phased array probes integrated into a fully automated testing system to meet stringent quality control ...

... rotating billet inspection system (RBIS) is a turnkey solution that uses phased array (PA) and eddy current array (ECA) technology integrated into a fully automated testing system to ...

... BIS-ECA is a fully automated turnkey inspection system that is integrated into the metal production line to monitor safety and quality requirements of raw materials in both round and square forms. ECA ...

Solutions for the ultrasonic inspection of long steel products Waygate Technologies' line of Krautkrämer ROWA™ Ux industrial automated UT systems are the most compact and simplistic solution for the ...

... automatically moves inside the machine. Features: • Final product test • Vision inspection system option • Product trigger option • 1U size lower rack structure • Barcode ...

... later on. Reduced Surface Defects The Surface Inspector provides the operator with up-to-the-second digital image feedback of the current jacket, bar or water soluble tape quality on any production ...

Taymer

... surface defects. The SI series has different camera configurations in order to adapt to your specific requirements. Reduced Surface Defects The Surface Inspector provides the operator with up-to-the-second digital ...

Taymer

... of the bar to be tested is completely immersed in water. The system uses a sealed water chamber and probe cassettes where the ultrasonic probes encircle the bar. In contrast to inspection ...

KARL DEUTSCH

... straightness tolerances of the bars (typically 1 mm/m – 2 mm/m) are compensated by the spring-loaded suspension of the probe holders. Therefore, this type of system is optimally suited for testing black ...

KARL DEUTSCH

... mechanical straightness tolerances of the bars (typically 1 mm/m – 2 mm/m) and optimizes this type of system for testing of black bars. Key Facts • Rapid bar testing ...

KARL DEUTSCH

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining