- Production Machines >

- Plastics Processing >

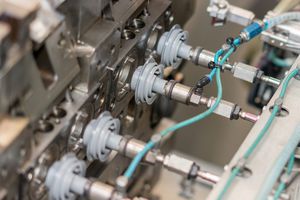

- Bi-material injection molding

Bi-material injection molding

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Injection Moulding The classic manufacturing process for thermoplastic products. By designing the injection tools based on the specific product requirements and by defining the correct production processes ...

Helvoet Rubber & Plastic Technologies B.V.

Injection Moulding The classic manufacturing process for thermoplastic products. By designing the injection tools based on the specific product requirements and by defining the correct production processes ...

Helvoet Rubber & Plastic Technologies B.V.

Injection Moulding The classic manufacturing process for thermoplastic products. By designing the injection tools based on the specific product requirements and by defining the correct production processes ...

Helvoet Rubber & Plastic Technologies B.V.

... finish and functionality for the luxury, perfume, cosmetics and spirits markets. Specialised in the injection and decoration of aesthetic plastic parts, our ambition is to accompany our customers in ...

... TECHNOLOGIES Mono-material injection Component overmoulding Bi- and Tri-injection Co-injection Heat and cool (Roctool) Gas injection Injection ...

Injection is a mastered technical field, mature, subject to strong international competition. Dedienne MULTIPLASTURGY® Group mobilizes its Research and Development teams to offer its customers differentiating technologies, ...

DEDIENNE MULTIPLASTURGY® GROUP

... sets and parts based on technical plastic material The production benfeitfs from a pool of 17 modern, high performing électric & hydraulic machines from 25 to 400 T clamping force. The assistance ...

... cosmetic characteristics. Beyond materials, injection moulded parts can have custom finishing, polishes, or surface textures. Xometry offers both high-precision tool manufacturing and injection ...

Subcontracting plastic injection parts rather invariably leads to high investment in tooling which may impact your project viability from the start. That is why we offer very low tooling costs to our ...

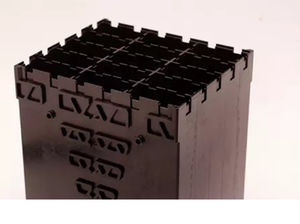

2-component plastic parts meet high requirements of optical and mechanical specifications. Material combinations are produced in the 2-component injection moulding procedure up to a parts ...

RAUSCHERT

Mould-Precision Stamping Mould Mould Material: <300℃ Zinc AlloyCr12, Cr12MoV, S-136, SLD, NAK80, GCr15, T8, T10 300~500℃ Aluminum Alloy, Copper Alloy 5CrMnMo, 3Cr2W8, 9CrSi, W18Cr4V, 5CrNiMo, W6Mo5Cr4V2, M2, 500~800℃ ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining