- Production Machines >

- Plastics Processing >

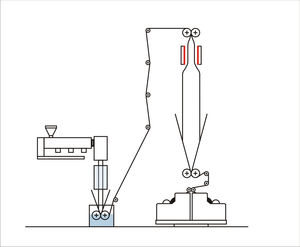

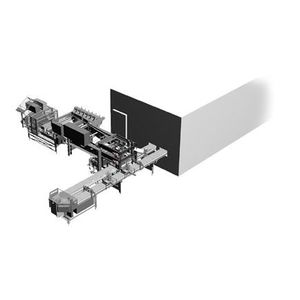

- Blown film extrusion line

Blown film extrusion lines

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

YVROUD blown film lines are generally intended for the development of the continuous manufacturing process for the product. They are mainly installed in research centres, ...

YVROUD blown film lines are generally intended for the development of the continuous manufacturing process for the product. This equipment is designed to produce ducts: •with ...

... sticky and very wide film TYPICAL FILM APPLICATIONS INCLUDE Consumer Packaging: with food-contact Consumer Packaging: non-food Industrial Packaging Specialties, like barrier, stretched film ...

W&H Group

... without energy and cost intensive pelletizing. Make films with a recycled content a profitable business and make yourself a pioneer in the plastics industry. Fluff to Film Making new film ...

Reifenhäuser Extrusion Technology GmbH & Co. KG

The Customized High-Output Blown Film Line for Demanding Applications • Produce a wide product portfolio with one machine • Use the largest process window of all machines on the market • ...

WINDMÖLLER & HÖLSCHER

... quenched film systems, film winding and many other film production solutions, particularly for food packaging. In addition, to complete lines for co-extruded film ...

Film to Film 2 in 1 Blown Film Line This new style film-to film tubular blown film ...

7 Layer Co-Ex blown film lines meets a majority of the industry’s critical packaging development needs. 7 layer co-extruded blown film line ...

Rajoo Engineers Ltd.

Windsor Machines creates the state-of-the-art MAGNATE series – 7 & 9 layer co-extrusion Blown Film lines in collaboration with the Kuhne Group, Germany. The line ...

... water cooled blown film line that is well-suited for those seeking a high output co-extrusion line. With Alpha Glacier, customers are able to see and ...

... opt.) embossing // winding Combiwind® unwinding // Production features PE film shrink film stretch hood stretch film agri stretch film Format Mother roll with ...

COLINES® S.p.A.

... . Automatic film thickness adjusting die head, double stage cooling water ring, vacuum sizing water ring, reversing haul- off unit and so on, can be chosen to meet different film formula and requirement. ...

Mini Blown Film Line Tubular lay flat width:From 40mm to 7 meter. -MONO LAYER, TWO LAYER, THREE LAYER & FIVE LAYER -SINGLE COLOR, DOUBLE COLOR, UP TO 4 COLOR. Resin HDPE Film ...

Fong Kee Iron Works Co., Ltd.

Compact Blown Film Line JC-HM Sériés Blown Film Extrusion Line is the most cost-effective solution for high speed ...

A complete monolayer line available in two package configurations with extruder 55 or 65 mm that thanks to a strong economy of scale is available at a very competitive price. A simple and versatile machine ...

MACCHI

LDPE/LLDPE HIGH SPEED FILM BLOWING MACHINE Main Features: SUITABLE MATERIAL LDPE Specification: HP-25LD SUITABLE MATERIAL LDPE MAX. FILM WIDTH ...

... quality of films; Reduction up to 20% in the expenses with electrical energy. Aiming technological innovation, maximum output improvement and simple operation, Carnevalli presents its new E-40 extrusion ...

... and we are able to develope any laboratory equipment in the field of extrusion. 1 layer blown film extrusion. 5 layers blown film extrusion. Pipe ...

... of die to produce smooth film, more output and less waste Purcahsing fully automatic cut & change reel winder makes machine more automatically & saves time of operators Purchasing a LDPE/LLDPE die can produce LDPE/LLDPE ...

Chyi Yang Industrial Company

... application film that you want to manufacture? 2. What kinds of raw materials, HDPE, LDPE, Recycled or other materials that you use to manufacture your film? 3. The application film ...

HAN KING PLASTIC MACHINERY CO.LTD

... layer film that it produces is 30% stronger than film produced by a mono layer extruder. The ABA machine is also much more economic comparing to an ABC three layer machine as it has one extruder ...

Macro's polyolefin (PE) biax series of double-bubble film lines produces high performance multilayer shrink films for a variety of applications. each model is designed for efficiency ...

The compact extrusion & hardening solution BT-C extrusion lines are a very compact and flexible solution for producing a wide range of extruded products on one production ...

The Blown Film Unit is a compact unit for blowing, cooling, take off and wind up of extruded hoses. It is suitable for production of small films used by the food industry ...

Extruder unit: Main motor Screw, L/D ratio of screw: 28:1 Barrel cooling Gear Box Heaters: aluminum heaters Die: HD¢120,LD:¢250 With rotary die Equipped with adjustable stabilizing balloon basket Take up unit There ...

Zhejiang Deguang Machinery Co. , Ltd.

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining