- Production Machines >

- Other Manufacturing Equipment >

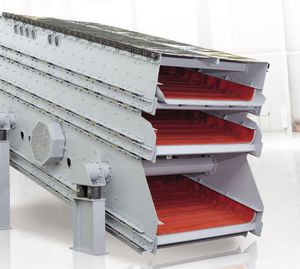

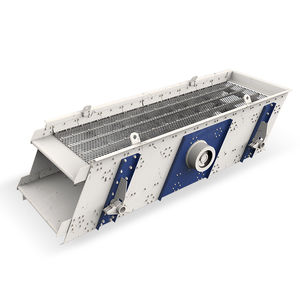

- Bulk material screener

Bulk material screeners

Engine power: 7.5 kW

... processing plant. They are used to classify materials both in different stages of the crushing process and in final product separation. Designed as a non-welded frame with adjustable vibration features for different material ...

MEKA Crushing Screening and Concrete Batching Technologies

... necessary, a washing system with spray sprinklers may be installed. Suited for fine or coarse classification of any type of material and for a wide range of productions. The vibrating screens consist of a screen deck ...

Weight: 22,000 kg

Engine power: 93 kW

Supported by a strong chain chassis, the 2F star screen on crawler tracks masters even tasks in difficult terrain safely and efficiently. Its different areas of use in waste management include biomass and soil preparation according to ...

Weight: 27 kg

Capacity: 350 t/h

Engine power: 55 kW - 88 kW

Unrivaled Performance Standard heavy duty plate apron feeder and hydraulic folding hopper walls Double deck screen box 4.200 x 1.500 mm (14’ x 5’) 6,3 m² screening surface upper deck, 5,4 m² lower deck Available in full hybrid version Contractor’s ...

keestrack

Weight: 29,484 kg

Engine power: 93.2 kW

With a 6 ft/1.83 m drum and a hopper that holds 6 cubic yards/4.6 cubic meters, the TR626 makes short work of processing material. Access the drum through removable side panels, drum end or top of the ...

The POWERSCREEN® CHIEFTAIN 1400 is one of the most in demand screening models by Powerscreen. One of the advantages in using this product includes a faster assemble time using its hydraulic folding conveyors. It also has the capacity ...

Powerscreen

Weight: 16,500 kg

... designed to handle heavy duty jobs. Whether it is blasted rock or bulky demolition material, thanks to their enormous throughput the RM HS series screens minimise material handling and ...

RUBBLE MASTER HMH

... with manual or pneumatic tensioning devices for the screen linings. • Twin vibrating motor drive. Executions: Our screening machines can be supplied with tailored ancillary equipment to meet the specific requirements ...

Vibra Schultheis

AViTEQ-Vibrating screen are robust, durable, bulk material adapted heavy workers, which are used as discharge units with integrated screening function below a silo, hopper or bunker or to provide a feed ...

AViTEQ Vibrationstechnik GmbH

... mechanism provides two vibratory movements in which flexible polyurethane mats are expanded and compressed in turns. The material is separated at high acceleration. The dynamically excited screen mats thus remain free ...

Dieffenbacher

Weight: 982 kg - 13,400 kg

Screening surface: 4.2 m² - 14.4 m²

Engine power: 5.5 kW - 30 kW

... Widely used for materials classification in industries of mine, building materials, communication, energy and chemical industry etc. Suitable materials: shale, coal, mica, baritic rock, ...

Luoyang Luoyang Yu, Science & Technology Co., Ltd

... shavings (for production of animal bedding) or mineral fractions from old wood and for making other quality improvements to materials for recycling or thermal treatment. They essentially consist of circular oscillating ...

Vecoplan

... . It is mainly used for the grading operation of cold materials with temperatures below 150°C . The series screens can be installed on the left or right side according to the conditions of the work site. ...

Xinxiang Gaoke Mechanical Equipment Co., Ltd.

industry screenerKonti

The JEL Konti vibro sifter is suitable for various bulk solids and screening tasks. Thanks to its ergonomic construction and tool-free operation, the vibro sifter will win you over with its simplified ...

J. Engelsmann AG

... produce a certain amplitude of circular motion, and the material on the inclined screen surface is subjected to the impulse of the screening box and is done a continuous throwing motion. When the material ...

GEP ECOTECH CO., LTD.

... fine screening equipment that achieves high-precision materials and large processing requirements. Its screening accuracy and efficiency meets all fine and ultra-fine powder and particulate materials, ...

Henan Pingyuan Mining Machinery

... drives screen surface to make periodic shaking, which makes the materials on the screen surface to make directional jumping movement with the screen box. During the period, the material less than the ...

Xinxiang Weiliang Sieving Machinery

... results and ideal for highly demanding products such as pharmaceuticals, plastic granules, chemicals and powders as well as all kinds of (animal) food. Quick-cleaning screening machines and conveyors Why ...

Spaleck GmbH & Co. KG

The EDGE TRM622 Mobile Trommel screen combines high production rates with ease of use in a robust, portable and versatile screening plant that is ideal for applications such as top soil, recycling, composting and is proven in construction ...

EDGE Innovate

... this way it is possible to process many different materials, such as sugar, coffee and other similar products. The rotary sifter is typically used as a security device before stowing or loading in bulk, ...

G&AS

... circular screeners for ‘safety screening’ powders at critical check points. The units feature a central inlet and a central outlet with twin motors, one motor mounted on each side of the machine. The design allows for ...

Virto Group

... inclination angles. Its unique structure makes it more suitable for working conditions with a large number of fine particles in the material, and the classification effect of medium and fine coal is more significant. ...

Shijiazhuang Huatao Import And Export Trade Co.,Ltd

Engine power: 200 W

... ultrasonic powder screening machine is composed of ultrasonic vibration system and sieving machine with unique technology. RTUL’s Ultrasonic Powder screening machine is used for screening ...

Roop Ultrasonix Ltd

Weight: 5 kg - 16 kg

Screening surface: 3 m² - 14 m²

... plastic, grinding material, chemical engineering, medicine, building materials, grain, carbon, chemical fertilizer, fire-resistant materials, mine, coal, metallurgy, etc. and for screening ...

Zhengzhou Dingsheng Engineering Technology Co., Ltd.

The Oscillating Sieve is a highly efficient equipment in the process of cleaning and separating bulk products, it can work in pre-cleaning and in the classification by size of elements. It was designed ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining