- Production Machines >

- Other Manufacturing Equipment >

- Bulk material screener

Bulk material screeners

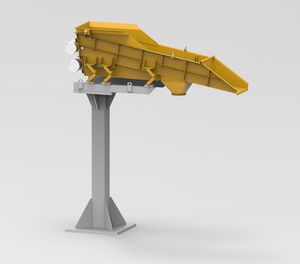

... gravitational assistance. Common Applications Include: Screening bulk materials, such as powders, plastic pellets, aggregate, or scrap metals Benefits of the EMS Electromechanical Screener ...

Cleveland Vibrator

... single-deck version has two outlets (one for pellets, the other for fines). The double-deck version has three outlets (coarse material, pellets and fines). The cover is secured with quick-release fasteners for simple ...

ottevanger

The FSM Trash Rack Screen has been developed in reference to the increasing demands of users. These resulted in an optimum product for- coarse cleaning of waste water - providing high performance coupled with low operating costs. The ...

FSM-Frankenberger GmbH & Co. KG

IFE linear motion vibrating screens are used for screening of granulous bulk material. The robust screen frame is manufactured, depending on the application, either in welded or in bolted and glued design. ...

IFE Aufbereitungstechnik GmbH

... values with the conical opening finger screen system in cascade shaped arrangement – there is firstly a breaking up of the material and secondly a screening with comparatively few blockages. For best separation results, ...

JÖST

... manufactured parts or broken tools cannot be avoided? No problem – using a screener from Lanner will reliably separate the tramp metals and the further processing will work out fine. The screeners ...

Weight: 18,000, 12,000, 8,000, 26,000 kg

... The Polygonmach Vibrating Inclined and Horizontal Screens provide an unmatched screening solution for various types of materials. Whether you're dealing with heavy-duty rock or fine aggregates, these screens offer robust ...

Polygonmach

... screening separates and removes non-dissolved solid materials that could cause mechanical damage and blockages to the next treatment steps in the wastewater treatment plant. HOW DOES PRIMARY SCREENING WORK Influent ...

Weight: 19 t

Engine power: 40 kW

... Powerful screening ability Wide usage scenario Convenient transition Accessories completeComplete spare parts and screener support TECHNICAL PARAMETERS Hopper - Feeding capacity (t/h) - 200 - Max Feed ...

Guangxi Mesda Engineering Machinery Co., Ltd

Weight: 9,500 kg

... machine. By preventing the entrance of coarse materials that are subjected to pre-separation into the screen with the slope adjustable bunker grid, it adds an additional sieving property to its separation of materials ...

Evortle Mobile Crusher and Recycling Plants

... KOMPATTO SC 221 tracked screening machine is the smallest self-propelled screening plant on the market today. Lightweight, compact-sized and featuring a robust chassis, it was designed for rubble and debris screening ...

Komplet Italia srl

Weight: 6,500 kg

... and a 10ft x 4ft double vibrating deck, allowing for high screening rates and handling of a full range of materials, including waste, soils, glass/metals and wood chips. • VARIABLE SPEED FEED HOPPER • ...

... tensioning 90 degrees, thereby positioning the crown of the screen parallel to the material flow. This change in crown orientation assures an even distribution of material across the entire width of the ...

Derrick

Weight: 250, 72 kg

Sand Sieving machines are manufactured with the highest quality raw material. These Sand Sieving Machines are used to sieve sand on construction sites.These machines can be used for residential ...

Safari Construction Equipments Private Limited

... failures through dust, humidity and vibrations. The powerful 2-deck, 2½-deck, and 3-deck screening machines ensure a high level of throughput and precise material separation. The screen box is supplemented ...

GIPO AG

... used in this machine. It is especially suited for smaller companies and recycling centers, where work is dictated by processing many different types of materials within tight schedules, while reliably ...

Doppstadt

Tumbler screening machines are used for a wide range of separation tasks in the bulk materials industry, from protective screening to dedusting. They are particularly suitable for fine ...

Screening surface: 20 m²

Engine power: 40 kW

... regarded as one of the most effective separation methods for organic waste. Precise separation selectivity regardless of material moisture, and particle size change at the press of a button are particular features of ...

Weight: 80 kg

... system that exploits undulatory and shaking motion to separate the material from the dust/chips, thanks to the presence of a perforated surface over the entire length of the screen. The material is also ...

Capacity: 2,500 kg/h

It is a machine used for cleaning wheat, barley, oats, rye, lentils and vetch. It consists of four units: Feeding - Cleaning - Classification - Disinfestation. It is a machine that cleans foreign seeds and substances in the product ...

SRD Machine Agriculture and Construction Industry Trade Limited Company

Vibrating screens designed for a first rough selection of materials. In particular, they expand and distribute the material before the optical sorter. Separation from the structure by means of springs. The ...

... presents the ability to separate fine particles (from 10mm to less than 10µm) of difficult, dry, wet, adhesive or sticky materials. Thanks to the acceleration generated, the capacity and the efficiency of screening ...

... spreads material across the deck for maximum utilization of the screen area. Tapered finger designs along with unique cam-out surfaces and staggered positions help to prevent material bypass. Separation ...

General Kinematics

Capacity: 15 t/h - 70 t/h

... separating of granulates and powders. Once the material enters the sieving compartment, the variable, rotational forces and sieve (deck) trays split the smaller fractions from the larger ones. Residue material ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining