- Production Machines >

- Other Manufacturing Equipment >

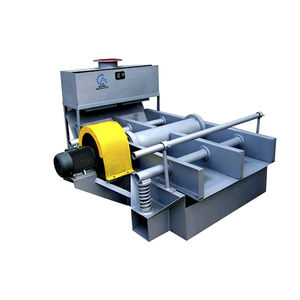

- Bulk material screener

Bulk material screeners

Engine power: 7.5 kW - 60 kW

Application: Mining, building materials, transportation, energy, chemical and other industries product classification. Materials: River pebbles, granite, basalt, iron ore, limestone, calcite, ...

Vibrating Screener can be supplied of different sizes depending upon capacity required. They can also handle slightly wet material. Inlets, outlets and legs can be custom fit to your installation requirements. ...

Jinan Taichang Transmission Machinery Co., Ltd.

Centrifugal dehydrating screens working statically they can work without special strengthening as bottoms and beds in tanks or storage and sewage reservoirs. They are used for desludging and dehydrating of small coal ...

Progress Eco

... tumbling screens are typically used to sieve extremely fine and/or lightweight products (food flour, micronised materials, mineral powders, plastic powders). Should we use a typical vibrating screen, ...

ERIMAKI

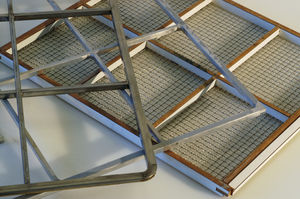

Under the brand name SEFAR NYTAL we offer a comprehensive range of fabrics specially made for plansifters. The open-mesh polyester, polyamide and wire mesh fabrics are available as ready-made products, as well as roll goods. With over ...

Sefar

... process Processing capacity: Depending on the process Applied material: river pebbles, rocks (limestone, granite, basalt, diabase, andesite, etc.), ore tailings. The Handling Materials ...

Henan Hongxing Mining Machinery CO.,LTD

The Single channel sifter mod. BM is used mainly in mills, feed mills, pasta factories, biscuit factories and in the food and chemical industries to calibrating floury products. Since above-mentioned data are approximated and could change, ...

Defino & Giancaspro

The Joyal Vibrating Feeder GZD-1300x4900 is a linear direction feeding machine. The feeder can send shaped and granule materials into the crusher evenly, timely and simultaneously. The machine vibrates smoothly. Its ...

Engine power: 5.5 kW - 30 kW

... and these parts are called under-screen materials, and the materials larger than the mesh opening go towards the front chute before they can pass through the screen panel. These materials ...

... screens are the ideal solution for controlling the particle size of wet and sticky materials. Each screening axes consists of many discs that set in motion the material to allow its screening, and its ...

Screening surface: 33 m²

... plant / trommel screen, for example, is regarded as a classic machine, and is effectively the flagship among the drum screening machines across all manufacturers. The T 60 mobile trommel screen achieves impressive ...

Eggersmann Recycling Technology

The SCALPEL screen is fed directly into the output of a pre-shredder. In the process, the SCALPEL roller screen removes long and bulky objects ("OVERS"), which can lead to the disruption of the subsequent separation line. The throughfall ...

... and does not need any maintenance. HUCK bolts are used to fasten the lining plate. Buyers can choose from a variety of materials for the lining plate, such as HARDOX, manganese steel, polyurethane and ceramic. Other ...

Henan winner vibrating equipment CO.,LTD

The AKA-SCREEN is a wet classification technology used to produce fractions with sharp eut sizes in fine grain Screening. PrincipLe of operation The AKA-SCREEN consists of up to 5 individual screen decks, screen layers made of polyuréthane, ...

... MEX VS-200 series Vibrating Screen separator is Monomex’s solution for separation of rubber or plastic pellets.It is also an important accessory for plastic and rubber strand pelletizer process and pellet ...

... can also be used to remove dust & fines from granular materials. Beccaria rotary powder sifters have been constructed to meet or exceed the requirements of ATEX Directive 94/9/EC. DESCRIPTION Material ...

... , wheat, maize (corn), rye, oats, etc. The oscillation of the double deck sieves efficiently removes both large or coarse material, and fine impurities from the grain being cleaned. The SFI is available as a Silo rice, ...

SATAKE

Features 1. Applicable for all kinds of reject handing at the last stage of screening and separating. 2. Adopting double-row self-aligning roller bearing, reliable and stable operation. 3. Perfect screening ability with self-washing, ...

Qinyang Aotian Machinery Manufacturing Co., Ltd.

... installations. Straight-line product supply and removal to facilitate post-sieving product distribution: bag packaging, Big bag, bulk and composition… Made from passivated stainless steel 316 L. Polished mirror ...

Sodeva

... CLEAN CANTILEVER DESIGN KEK SIFTERS KEK Centrifugal Sifters provide the ideal screening solution for dry powder and other bulk solid. The ‘Cantilever’ design offers users high standards in hygiene and ease of operation ...

Opening of the mesh: 100 µm - 200 µm

... types of contamination and significantly reduce your waste powder ratios. Depending on the amount and consistency of the material being sieved, the MS Ultrasonic controller automatically matches the oscillation frequency ...

... Vibrating Screen Adjustable, Flexible, Professional, Advanced Mobile Vibrating Screen is equipment providing screening work for coarse crushing and medium crushing. By changing the model of screening plant, we can ...

CST series industrial vibrating screener for classification and separation. Suitable for separating, classifying and sorting all kinds of materials into different sizes and fractions.

... force of excitation force and material self-weight force, the material is thrown and jumped forward to make a straight line motion on the screen surface, so as to achieve the purpose of screening and ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining