- Hydraulics - Pneumatics >

- Filter and Separator >

- Bulk material separator

Bulk material separators

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

... vibratory separator accurately grades particle size fractions The Finex Separator™ is the ultimate solution for quickly and accurately grading or sizing powders. It can also separate heavy or sticky ...

... magnetic separator is a permanent separator made by using high quality NdFeB magnetic elements. The surface intensity can reach up to 1.3T, this removes the ferrous minerals comingled with non-ferrous ...

Filtration size: 0.03 mm - 3 mm

... high intensity magnetic separator consists of driving rollers, magnetic rollers and a transfer belt. the ferrous particles are attracted by the magnetic roll while transferring to the magnetic field, then the non-ferrous ...

Width: 300, 400, 380 mm

Weight: 28, 45, 82 kg

... the product, the magnet separators comply with the international regulations of the EHEDG, BRC and IFS for hygienic design, and guarantee high food safety standards. Easy to clean, less wear and tear The design of ...

... applications, up to 100°C, high-energy neodymium magnets are often used and for even higher temperatures, a special samarium-cobalt material can be supplied. Function: The MAGBOX MXF FOOD/PHARMA is designed mainly ...

Sesotec GmbH

... Its outstanding ease of handling and cleaning are further positive features of this magnet separator. A low installation height (165 mm) and customer-specific connection dimensions facilitate retrofitting. ...

Sesotec GmbH

... the installation of material loaders, mixing and dosing units directly on the magnet separator. With its special design the SAFEMAG does not allow any depositing of plastic granulate ...

Sesotec GmbH

magnetic separatorWHIMS series

... concentration of feebly magnetic materials. Typical applications include hematitic iron, rare earth minerals, industrial minerals and more. Features: Excellent performance on even weakly magnetic materials: ...

... form. Material surface characteristics Material size Function Material separation with the cascade sifter function is as follows: The input material is ...

1

Weight: 910 kg - 8,500 kg

... centralized control The magnetic separator is made of Permanent magnetic plate, 8mm Belt , Motor, Iron frame. The permanent magnetic plate is belong to the magnetic system which can absorb the iron from the raw material. ...

Flow: 1 m³/h - 15 m³/h

... crushed materials, non-ferrous metal glass slag, electronic waste, multi-metal (copper,, aluminium, zinc) mixture, garbage burned metals slag, plastic and metal mixtures, etc. Eddy Current Separator ...

... Concentric Eddy Current separators For this type, the magnetic rotor is mounted in the middle of the revolving drum. This results in a large separation angle which is desirable for some product types. This type of ...

Eddy current separators are widely used to separate non-ferrous metals (aluminium, copper, brass, etc.) from all kinds of down stream bulk material. Many research institutions and ...

... minerals, removing iron from non-metallic materials, and improving the purity of materials. Including ceramics, granulated slag, iron ores, plastics, silicones, ilmenite, mica, crushed glass, refractory ...

The magnetic drum/separator is intended for automatic cleaning of mixtures containing larger amounts of iron and iron oxides, which we want to separate from the raw material/ore itself. Due to the ...

... . New solution for vertical air transport (up flow of the material). Very robust, for heavy working conditions, but adjusted to your line. With new automatic cascade magnetic separator, you can ...

MBS magnetic drum/separator - neodymium MBS contains magnetic drum in housing. Magnetic drum removes micron ferromagnetic particles and oxides from the product. Suitable for product flows that contain big amount of ...

... ERGA DrumMag magnetic drum separator is installed at points of material discharge from conveyor belt or vibrating feeder, providing continuous high quality removal of magnetic impurities from dry bulk ...

ERGA

... magnetic separator for continuous recovery of tramp metal of various sizes from dry bulk material. - Efficient recovery of magnetic inclusions with ...

ERGA

... magnetic separator for continuous recovery of metal inclusions from fine dusty material. - Minimum losses of fines during separation: The separator is specially designed ...

ERGA

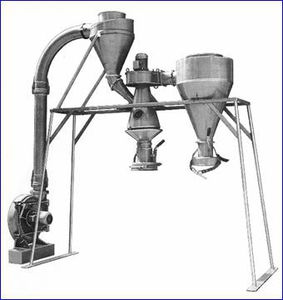

... of bulk materials, often considerable quantities of fine particles (dust) accumulate which must be reliably separated and which then represent an important economic recyclable material ...

... easy cleaning. 2.A wedge-shaped baffle at the top of the housing can prevent materials from bridging and choking and also can break up the caked material which makes the material flow ...

Ningbo Souwest Magnetech Development Co., Ltd

... drum is driven by a motor. Features: 1.Continuous self-cleaning design is suitable for automated production line. 2.Surface material is 304 or 316L stainless steel which is in good corrosion resistance. 3.No electric ...

Flow: 300 l/h - 1,000 l/h

... Turbidity meter Lower section of frame cladded in stainless steel Moveable work bench with crank gear for bowl assembly Spare bowl for quicker processing of the solids abstractions Available ...

GEA Westfalia Separator

... They continue to be the magnets most frequently used to improve the product purity of dry bulk materials. This separator provides “Final Magnetic Action” on bulk foods, ...

... with two or more cartridge trays arranged so that the cartridges are staggered to increase contact with the product stream. Material moves in a zig-zag pattern from one cartridge tray to the next for exceptionally thorough ...

BUNTING

... is used to de-cluster mechanically harvested green beans. The cluster cutter consists of a large drum which consists of plastic segments mounted in rings, between which eccentric steel plates are mounted in such way ...

... other properties associated with the particle size (eg. flour and bran). In order to make the granules contact with the separator as often as possible, the product to be separated is moved by vibration. The vibrating ...

Flow: 1,100 ft³/h - 40,000 ft³/h

... the flux of oriented high power permanently magnetic magnet material on the pulley’s peripheral surface. The radial pole field design is arranged for large and cylindrical shaped ferrous material, minimizing ...

... your product may contain. At Dragoelectrónica, we have designed and manufactured a drum magnetic separator that is easy to integrate into any bulk solids process, where the separation ...

Flow: 34 m³/h - 154 m³/h

Width: 250 mm - 1,112 mm

Weight: 130 kg - 370 kg

... series air-gravity separator is well suited for the continuous separation of all types of foreign bodies from free-flowing bulk materials. Dosing occurs in combination with a dosing screw, ...

The separator is designed for dry separation of mixed loose materials; specifically, the machine is used to separate polymers with different electrostatic charges. The separator is ...

CAMEC srl

Separator of simple use and regulation with very low maintenance. Separation of hollow bodies from flat bodies. Film, paper sheets, flat materials will exit from the above part, the materials ...

The DENSE-OUT® is a dry classification tool that uses vibration to stratify and air to separate bulk materials based primarily on differences in density. The DENSE-OUT® helps produce cleaner and more ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining