- Packing - Handling - Logistics >

- Packing and Packaging >

- Can seaming machine with vacuum technology

Can seaming machines with vacuum technology

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Throughput: 8 p/min

... lid onto the can. Passing the lid in position check, cans are transferred onto the seamer lifter plate. The can is raised to the gassing position where a silicone seal inflates around ...

Innovus Engineering

Throughput: 6 p/min

... is a pneumatically-actuated motor-driven can seaming system that is used in a variety of industries to double seam filled cans in a nitrogen-flushed vacuum environment. Applications ...

Innovus Engineering

Throughput: 6 p/min

... Innovus 10DVG is a pneumatically-actuated motor-driven can closing machine. It is widely used in many sectors of pharmaceutical and industrial production for double seaming filled cans ...

Innovus Engineering

Throughput: 20 p/min - 25 p/min

... automatically. High precision, adjustable vacuum and gas pressure microprocessors PLC controls are SIEMENS, all pneumatic equipment is FESTO, vacuum pump is German BUSCH Machine does ...

semi-automatic can seaming machineVGS SEMI-AUTO SEAMER 7 UPM

... final product. Before can is taken back to the line it is seamed, and it all happens in the same point. No need of extra equipment. The machine can be configured to work in 3 different ...

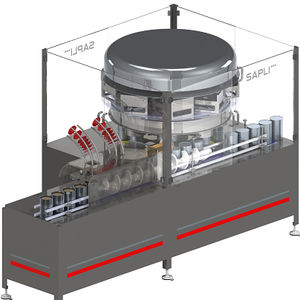

Sapli

automatic can seaming machineVGS1 AUTO SEAMER 7 UPM

... market highly-efficient cans seaming system, developed specially for maximum reduction of vacuum gassing and sealing cycle and achieving of the optimal level of Oxygen. Method (In-line ...

Sapli

... market highly-efficient cans seaming system, developed specially for maximum reduction of vacuum gassing and sealing cycle and achieving of the optimal level of Oxygen. Method (In-line ...

Sapli

... market highly-efficient cans seaming system, developed specially for maximum reduction of vacuum gassing and sealing cycle and achieving of the optimal level of Oxygen. Method (In-line ...

Sapli

... market highly-efficient cans seaming system, developed specially for maximum reduction of vacuum gassing and sealing cycle and achieving of the optimal level of Oxygen. Method (In-line ...

Sapli

MULTI STATION VACUUM GASSING AND SEAMING Sapli’s Vacuum Gassing and Seaming stations can be configured with or without vacuum-gassing ...

Sapli

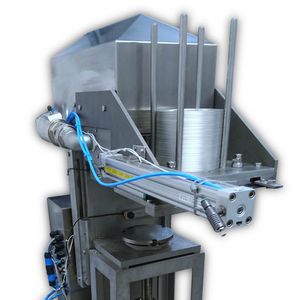

SINGLE STATION VACUUM GASSING AND SEAMING Sapli’s Vacuum Gassing and Seaming stations can be configured with or without vacuum-gassing ...

Sapli

Throughput: 1 p/min - 7 p/min

... feeds the cans to the Sapli machine, installs them in a special area on the lift mechanism platform, where the cans are gripped with special fasteners. 2 - The platform with the can ...

Sapli Cans Technology

Throughput: 1 p/min - 7 p/min

Automatic Vacuum-Gassing and Seaming Station 7 cans / minute Machine extricates the oxygen from the container with the product. This space is refilled with Azote ...

Sapli Cans Technology

Throughput: 1 p/min - 21 p/min

Automatic Vacuum-Gassing and Seaming Station 21 cans / minute Machine extricates the oxygen from the container with the product. This space is refilled with Azote ...

Sapli Cans Technology

Throughput: 1 p/min - 36 p/min

... after sealing a certain number of cans, the intelligent system automatically controls the quality of the seal. The seamed can with the product remains in the chamber for a little longer for control. ...

Sapli Cans Technology

Throughput: 1 p/min - 96 p/min

... market highly-efficient cans seaming system, developed specially for maximum reduction of vacuum gassing and sealing cycle and achieving of the optimal level of Oxygen. Production ...

Sapli Cans Technology

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining