- Production Machines >

- Other Manufacturing Equipment >

- Ceramic mill

Ceramic mills

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Rotational speed: 800, 1,600 rpm

FRITSCH Planetary Ball Mills – high-performance all-rounder in routine laboratory work The Planetary Mill PULVERISETTE 5 premium line with 2 grinding stations is the ideal mill for ...

Fritsch GmbH - Milling and Sizing

Rotational speed: 300 rpm - 3,000 rpm

Output: 60 kg/h

... fine tune the comminution process for each sample within a very wide range of applications. The high-speed Universal Cutting Mill PULVERISETTE 19 with a torque of up to 30 Nm comminutes dry, soft to medium-hard sample ...

Fritsch GmbH - Milling and Sizing

Rotational speed: 800 rpm

... GEOLOGY AND MINERALOGY • METALLURGY • CERAMICS • MATERIALS RESEARCH/ • MECHANICAL ALLOYING • NANOTECHNOLOGY • PHARMACEUTICALS • CHEMISTRY • BIOLOGY OVERVIEW FRITSCH Planetary Ball Mills ...

Fritsch GmbH - Milling and Sizing

... demanding customer requirements. We are the only company to offer basket, pin, circulation and passage mills. We have been building horizontal disc mills for more than 40 years, and over 4,200 machines ...

NETZSCH Grinding & Dispersing

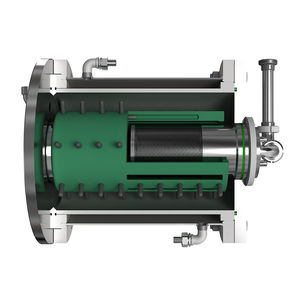

... closed horizontal agitator bead mill is designed for the highest product throughput rates and has a peg grinding system with extremely high grinding intensity. Easy and Reliable Operation The Zeta® ...

NETZSCH Grinding & Dispersing

The high-speed mill system Zeta® with improved peg grinding system optimizes your production capacity, energy demand and quality. Designed for circulation operation and multi-pass operation, you achieve ...

NETZSCH Grinding & Dispersing

Single Roller Mill EW-L Our Roller Mills have: A crushing ratio, usually 1:5 ... 1:15, whereby a maximum of 1:30 can be realized. An infinitely adjustable crushing gap, the crushing wall supported ...

Double Roller Mill WS-L The laboratory version of our two-roller mill is additionally equipped with a feed hopper, a base frame with collecting box and the control system, so that it is delivered ready ...

... can be chosen. For wet mills, replace sealing cover with sieve insert and stopcock, position drum with sieve at lowest point, then open tap to empty. Dry mills discharge crushed product through rotating ...

... manufactured, and installed more than 8,000 ball/pebble mills, all over the world. Both the ball and pebble mills utilize a tumbling media, ball mills with steel balls, and pebble mills ...

Output: 1 kg/h - 50,000 kg/h

... FNG is easy. The Universal mill is equipped with air insufflation at bearing level to eliminate all risk of cross-contamination in the case of multi-product use. The extensive FNG range starts with the FNG 00 laboratory ...

The BRF dual-rotor universal mill is an evolution of the FNG universal mill. The BRF’s design is based on FORPLEX impact crushers (such as the FNG or FPX models) but is engineered with two oppositely ...

Motor power: 1, 2, 11, 19, 37 kW

The PULVIS is THE energy-optimised grinding system for ultra-fine materials. The vertical, dry agitator bead mill features an integrated dynamic classifier. Its strength is the ultrafine and low contamination ...

... Stirred Media Detritor (SMD) is a fluidized media grinding mill. It utilizes the rotational energy of the impeller arms to impart a high-energy motion to the media and slurry mixture inside the mill. ...

Output: 1 t/h - 90 t/h

Motor power: 19 kW

Machine weight: 4 t - 65 t

... The dry type and wet grate type mill can be selected according to the nature of materials and discharging mode. The ball mill manufactured by our company has three (3) types: wet grate, dry grate and ...

Conical Mill, Co Mill, Comill Cone Mill is mainly used in processes such as de-agglomeration, wet milling and dry milling. In terms of de-agglomeration, it can effectively ...

Yenchen Machinery Co., Ltd.

... ® Grinding Mills are proven in dozens of milling applications. Grinding processors are achieving impressive energy savings (35-50%), thanks to a unique rotational material motion that is more efficient ...

Final grain size: 1 µm - 3,000 µm

Rotational speed: 800 rpm - 1,200 rpm

Output: 20 t/h - 70 t/h

... Grinding of ceramic bodies with moisture content less than 7% for bricks, roof tiles and other ceramic products, where a granulometry 0,6÷2 mm is required. Classification is obtained with vibrating screens. • ...

CIMMA

Final grain size: 75 µm - 890 µm

Output: 1 t/h - 90 t/h

Motor power: 19, 22, 37, 55, 75 kW

Ceramic ball mill is a kind of the best solution and specifically designed for high purity material. Inwall of ball mill using high alumina ceramic, zirconia, rubber ...

Output: 0 t/h - 25 t/h

Motor power: 19 kW - 160 kW

Machine length: 4,300 mm - 12,275 mm

... Introductions of High pressure suspension grinding mill: Dingbo High pressure suspension grinding mill is suitable for processing various non-flammable and non-explosive mineral materials with Moh’s ...

Motor power: 30 kW - 250 kW

Machine length: 1,650 mm - 3,900 mm

Machine width: 900 mm - 3,700 mm

... trouble, etc. Also this mill is fabricated with special hardened-steel of vessel, disc, shaft cover, separation rotor, etc. with hardened Cr alloy steel, SUS 420J2. This D.S Horizontal Mill is fully-developed ...

DAESUNG CHEMICAL MACHINERY IND.CO.

Output: 5 t/h - 210 t/h

... material. Raw material mill can be divided into ordinary raw material mill, air-swept mill, trail-discharging upgraded cycle mill and middle-discharging upgraded cycle ...

... roller will is the main component of the Migratech dry milling process for ceramic mixtures. It is a machine offering an exceptional efficiency. Its special construction allows for optimal milling ...

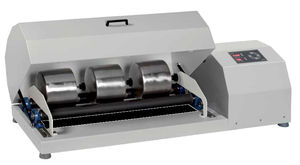

RAPID MILL WITH PLANETARY DRIVE, "MAGELLANO" SERIES, MOD. MAG3000/C WITH 4 ROTATING UNIT The requirement of some laboratories in the ceramic industry to be able to rapidly grind large frit quantities, ...

Ceramic Instruments Srl

Rotational speed: 50 rpm - 300 rpm

... makes it suitable for mill works in laboratories of public works, manufacture of paints, ceramic, milling of raw materials for the manufacture of pharmaceutical and food products.

Rotational speed: 35, 33 rpm

Motor power: 2 kW - 75 kW

Machine length: 700 mm - 3,600 mm

Clay Grinding Bail Mill Machine For Ceramics Bail mill is widely used in dry clay granding.

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining