- Food industry >

- Dairy processing >

- Cheese brining system

Cheese brining systems

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

... designed to provide a high level of cheese salting thanks to the FIFO system (First In, First Out). For these purposes there are different types of salting tubs built of concrete or stainless steel, depending ...

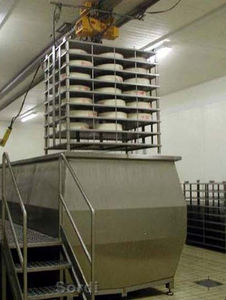

After pressing, the cheese forms need to be immersed in a brine for salting the cheese. Salt has roles in cheese besides adding a salty flavor. It preserves cheese from ...

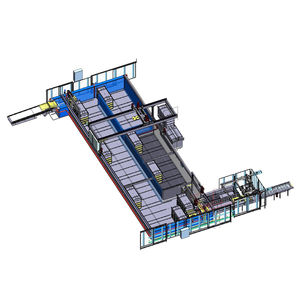

Brining systems Brining systems for salting in blockform or tray stacks as well as rack systems with manual or fully automatic loading and unloading

... brine time, and maximum use of floor space, the Tetra Pak® Brining system S has a proven record of reliability and superior performance. This system is designed to handle a variety of ...

It is suitable for salting by immersion pasta-filata cheeses like mozzarella, bocconcini and pizza cheese. Entirely built in stainless steel AISI316, equipped by: - a set of grids built with perforated ...

... ultraviolet light) system to disinfect your brine water and control the microbiological level. The system can be integrated into your brine water circulation system. ...

... and of the cooling. •Static Brining •Dynamic brining Salting / brining basin: Equipment for the salting of cheeses by immersion in a brine bath. Brining ...

... means of a brining flow; 4) With this type of plant, Grana Padano usually stays in brine from 16 to 18 days (pict.4); 5) After holding time in brine, the cheese is automatically extracted from the salting ...

... - Immersion baskets in stainless steel AISI 316 for cheese blocks containment; - Lifting system with sling bar with overhead crane for baskets. IMMERSION BASKETS FOR CHEESE ...

The dynamic cheese salting system is a whole set of equipment designed to complete the salting of forms of cheese by immersion in stainless steel vats containing a sodium chloride solution ...

... penetrates inside the cheese gradually. Salt concentration in the cheese is around 1% - 2%. Salting in brine is carried out by cheese plunging into vats with water and salt solutions. ...

... moves the floating forms. •As the tank empties of cheese, the pump resets and the level by recharging the brine. •The system is independent from the dimensions of the cheese forms.

... installations with automatic infeed. Besides its salting function, brining enables cheese temperature and bacterial cultures to be controlled, thus influencing the flavour of the cheese.

The cheese brine room is the room where salt is added to the product. The process of adding salt is accomplished submerging the product in a tank full of a solution of water and salt. This process prevent the formation ...

The automatic brine vat has the aim to assign to the cheeses the desired salting degree. The vats are dimensioned according to the cheese sizes to be salted and they are able to satisfy any Client’s need. Technical ...

... CONTINUOUS BRINING/BRUSHING MACHINE Designed for the treatment of: • salting on the sides and / or on product plans through the wet brushes with constant jets of water and / or the brushing treatment • the washing ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining