- Industrial machines and equipment >

- Surface Treatment Equipment >

- Clean-in-place unit

Clean-in-place units

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Cleaning-in-place (CIP) systems circulate cleaning liquids in a cleaning circuit through machines, processing lines and other equipment. CIP units for efficient cleaning of pipeline systems, tanks and processing plants with a choice ...

“Wetting/Washing in Place“ (WIP) and “Cleaning in Place“ (CIP) operations require very smooth surfaces with only few connections, free of gaps. Hygienic design is major to modularity. Typically, PPC (Pneumatic Pharma Conveyor) Vacuum ...

The Centec CIP units are very flexible systems for the fully automated cleaning of production facilities. Product leftovers and coats are removed to archive a clean biologically and physically surface. Therefor the Centec CIP systems ...

Exterbal cleaning system on wheels to be put in connection to the undervacuum homogenizer to feed the internal cleaning spray balls, thanks to water under pressure.

AXOMATIC

The CIP MONOBLOC is manufactured by E. Bachiller B. SA, and is a stage cleaning system specifically engineered for the cleaning of vessels which are utilized in the pharmaceutical as well as in cosmetic processes. The system primarily ...

CIP system working principle: Is to control the opening and closing of the steam valve by measuring the temperature sensor; to control the opening and closing of the water valve by measuring the level of the liquid through the pressure ...

Good to know You want a maximum hygiene system. With our Innopro CIP cleaning system we can give you just this. Specially developed for hot and cold cleaning this machine can sanitize your entire process and filling line. Microbiological ...

KHS GmbH

Our Mobile CIP: A stainless Steel Skid on wheels, compact and easy to connect with flexible hoses. Control by touchscreen, with Data History and remote control from your smartphone. Great Savings of Chemicals, Energy, Labour, and ...

Temperature of heated tanks is adjusted automaticaly. For full automatic system we have more options as follows: Dosing chemicals for empty / full tank, adjusting temperature, flow adjustment of chemicals, programming ability to choose ...

CIP : Closed-loop cleaning with recovery of washing solutions, for piping and closed-type equipment. Manual or automated system. Optimization of the hygiene and washing characteristics of equipment. Control of flow, temperature, ...

Regular, thorough cleaning maintains the quality of your products, increase the operational life of your machines and therefore protect your investments. You will find customised cleaning systems for every application and every requirement ...

The purpose of the CIP plant is to sanitize the production plant, by means of a particular sequence which provides initial rinsing, washing by means of alkaline and acid solutions, final rinsing with water. The wash program can be carried ...

INDIVIDUAL CIP SYSTEMS We design CIP systems according to your individual needs and specifications or work with you to design the CIP system during the project phase of other ultrapure media units, or we tailor your systems for pharmaceutical ...

We design and manufacture CIP and Mini CIP for tankers or food plants washing. These units are available in manual, semiautomatic and automatic versions. FEATURES: - Mounted on a stainless steel base; - Centrifugal pressure ...

Bailun Biotechnology is a leading supplier of intelligent data-driven bioreactor systems in China. Products cover all kinds of bioreactors in laboratory, pilot scale and industrial production, including fermenter, animal cell bioreactor, ...

BRS CIP systems are designed for effective cleaning of installation after processes or between batches. FEATURES •Affordable and reliable. •European-made components. •Easy maintenance and operation. •Swift and simple installation. APPLICATION •Fermentors, ...

CIP - Cleaning In Place -is a process to reliably and safely clean production lines. Bucher Unipektin has been manufacturing units of various types for years. The scope of supply comprises of simple manual units as well as fully automated ...

Bucher Unipektin AG

CIP (Clean-In-Place) systems are used for cleaning the equipment used in the production of beverages, beer, cider, fruit juices, foodstuffs, dairy products, pharmaceutical products, and generally in all those sectors that demand high ...

PRIAMO FOOD TECHNOLOGIES

•Automatic washing CIP. •CIP washing systems are designed and manufactured for the sterilization and washing of all types of milk tanks and machines. •The system provides a wash with water and soda and acid solutions. •Time and temperature ...

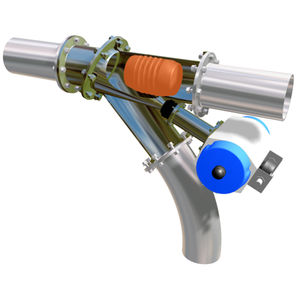

The entire pigging technology is controlled by a PLC that takes into account the detection and speed of the pig. The electro pneumatic valves are housed in a stainless-steel box. The method of pushing the pig through the transfer line ...

1, less cleaning fluid consumption. 2, reduce the cleaning time. 3, increase the utilization of equipment. 4, increase the operational safety. 5, the cleaning process to confirm the effect through the sensor.

CIP station is designed for sanitary cleaning of pipelines, buffer tanks, bottling lines, pasteurization plants to remove contaminants without the need of equipment disassembly. CIP station provides high performance and allows maintaining ...

CIP-stations are used for in-place cleaning of the technologic and packaging equipment in place of its usage. The stations perform preparation, warming and circulation of the cleaning solutions in product circuit of automatic machines, ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining