- Building - Construction >

- Construction and Mining Equipment >

- Concrete mill

Concrete mills

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Final grain size: 74 µm - 400 µm

Rotational speed: 21 rpm

Output: 16 t/h - 50 t/h

Ball mill is suitable to grind various mineral and other materials, which is widely used in various industries such as benefication, construction materials, chemical industry, etc, it has two ore grinding ways: dry way ...

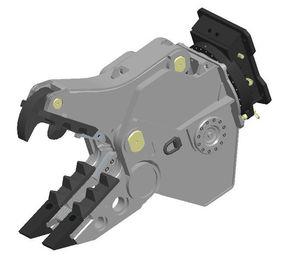

DLP rotating pulverizers available for excavators with 18 up to 50t / 39600 up to 110000 lbs operating weight featuring jaw depths of 800, 885 and 950 mm / 31.50, 34.84 and 37.40 in at closing forces of up to 1000, 1100 ...

... attachments for concrete crushing, scrap and demolition processing. Designed with small hydraulic machines in mind. Suitible for concrete crushing, scrap and demolition applications, cutting and lifting ...

Output: 150 kg/h - 200,000 kg/h

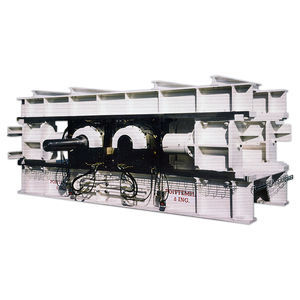

The POITTEMILL pendulum roller mill is a vertical mill that works by compressing the material bed. The pendulums mounted on a star wheel are driven by a vertical shaft. Each pendulum is fitted with a ...

Output: 5 t/h - 500 t/h

DESCRIPTION The Cylinder mill, commonly known as the Roller Press works by crushing the material between two cylinders kept under pressure by a hydraulic system (2 to 10 T/linear cm). This mill uses ...

Motor power: 1.5 kW - 45 kW

Machine weight: 1,200 kg - 11,000 kg

... Lime, Chalk, Cement, etc. Fuel processing : Coal, petroleum coke, etc. Coal, petroleum coke, etc. : Cullet, glass, concrete, bottom ash, etc. Chemical products : Fertilisers, Resins, Salts, etc. Options ...

Demolition pulverizer Rotar Demolition Pulverizer Incredible crushing power combined with tremendous cutting power makes the Rotar Demolition Pulverizer the perfect pulverizer ...

Rotar

Output: 60 t/h - 5,400 t/h

... industrial minerals. The smaller models of the are particularly productive in producing manufactured sand for asphalt and concrete production. How do you improve the industry standard for HPGRs? By taking proven grinding ...

... fragmentation of the demolished material making disposal and recycling easier by separating the reinforced iron from the reinforced concrete. Sturdy and compact structure The pulveriser is built with high wear resistant ...

Mantovanibenne

... which ensure outstanding penetration into the concrete during demolition. The front teeth go between the shrouds in the lower jaw, so the reinforcing steel is always separated optimally from the concrete. ...

Rotational speed: 85 rpm

... solids passing through without being macerated – typically an increase in capacity of 40% Can be installed in an existing concrete channel or in a fabricated frame, complete with guide rails, into existing submersible ...

Final grain size: 20 µm - 400 µm

Output: 300 kg/h - 10,600 kg/h

Motor power: 15, 37, 55, 75, 132 kW

... industrial minerals Features Centrifugal ball mill / Roller mill Plant layout and operation similar to conventional roller mills Advantages Simultaneous grinding and drying ...

Rotational speed: 940 rpm

Application: SDPP Pulverizer is designed to grind hard material to analytical size. It can be used in power industry, coal, fuel & chemical processing, metallurgical industry, building material, environmental industry ...

... solids passing through without being macerated – typically an increase in capacity of 40% Can be installed in an existing concrete channel or in a fabricated frame, complete with guide rails, into an existing submersible ...

Rotational speed: 150 rpm - 735 rpm

Output: 400 kg/h - 250,000 kg/h

Motor power: 22 kW - 1,600 kW

The main body of the rod mill is a low-speed rotating cylinder horizontally mounted on two large bearings. The rod mill is driven by the motor through the reducer and the surrounding large gears, or by ...

Output: 4 t/h - 300 t/h

... of advanced technologies of famous international corporations and 30 years’ experience in grinding mill production, SBM has launched the LM Vertical Grinding Mill which integrates five functions of crushing, ...

Shibang Industry & Technology Group Co., Ltd.

Motor power: 15 kW - 100 kW

Sound pressure: 100 dB

... thè appropriate toosl, can work almost any type of material introduced, wood, plastic, RSU, latin, fodder, soil, stone, concrete, bricks, glass, fiberglass, etc. giving thè desired size, thè power consumption is less ...

Final grain size: 10 µm - 20 µm

... soundproofed safety cabin. It is used in the grinding process of fragile materials and minerals such as basalt, bauxite, concrete, chrome, vanadium, dolomite, ferromanganese, ferrovanadium, granite, coal, quartz, silicate, ...

Rotational speed: 12 rpm - 45 rpm

... speed of the mill and on the size of the grinding pebbles. These mills are available in versions from 100 l up to 50,000 l and are ready for installation on bases made of concrete ...

Output: 20 t/h - 100 t/h

Motor power: 315, 132, 200, 55 kW

Machine weight: 4,400 kg - 12,500 kg

Rotor impact mill The rotor impact mill is a high-performance crusher with a vertical shaft. The rotor impact mill enables you to achieve a high reduction ratio and excellent particle ...

Final grain size: 1 µm

Output: max 200.0 t/h

The Soldo Cavitators wet mill can be used with any type of fluid, any viscosity and density, and to mix gases and solids as well. It can be installed in batch, batch-recirculation, semi-batch and continuous. It uses ...

Rotational speed: 85 rpm

... solids passing through without being macerated – typically an increase in capacity of 40% • Can be installed in an existing concrete channel or in a fabricated frame, complete with guide rails, into existing submersible ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining