- Industrial machines and equipment >

- Surface Treatment Equipment >

- Shot blasting machine

Shot blasting machines

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

The Blastrac 1-8DPS30 walk-behind shot blasting machine is optimal for small to medium-sized jobs. It is very easy to operate and handle. The machines self-propelled operation improves ...

Husqvarna

... walk-behind shot blasting machine optimal for small to medium-sized jobs. It is ideal for cleaning and preparing surfaces such as concrete and asphalt before the application of a new coating. It is also ...

Husqvarna

... walk-behind shot blasting machine offers a high level of versatility and can handle most small and medium-sized jobs. The machines self-propelled operation improves productivity and it ...

Husqvarna

... plates are added. ABRASIVE REMOVAL UNIT Rotating brushes remove the shot left on the workpiece after the blasting process. A rotating screw conveyor is integrated to bring the shot ...

FICEP

... Range automatic shot blasting machine is designed using the highest quality components for shot blasting plates and profiles for an optimal finished steel surface. Pre-installed ...

... , circlips etc. A stainless steel basket is available as an option if required; for instance, blasting medical components. This compact batch blast machine delivers: Fast cycle ...

GUYSON

... components such as aerospace fasteners, screws, bolts, nuts, washers, circlips, carabiners etc. Guyson's range of Tumbleblast machines all offers highly effective batch blast finishing of small components. Both systems ...

GUYSON

... create an automated post-processing system specifically for EBM (Electron Beam Melting) additive builds. The Powder Recovery System (PRS) blast system comprises the blast chamber, with build box integration and containing ...

GUYSON

... manufacturing process and high material output. Another field of application for the roller conveyor blast machine is the blasting of large machine constructions. In ...

AGTOS GmbH

Hanger-type blast machines are among the most flexible types of blasting equipment. They are used to remove rust, scale, sand and burrs from many kinds of work pieces. Hanger-type machines ...

AGTOS GmbH

... most effective blasting process for removing sand, scale and burrs from heavy or sharp-edged mass production parts that require the robust steel mill design found in our Model MR tumble blast machines. ...

AGTOS GmbH

1. It is suitable for different production scale. lt could be stand-alone use and many units can also be used together; 2. It could get good clean effect for complicated and small workpiece. 3. It can realize the automatic loading and ...

Shandong Kaitai Shot Blasting Machinery Share Co.,

... unloading, high flexibility, compact structure, simple maintenance. Production Application The product is mainly used for machining tool factory, automobile factory, textile machinery factory, heat treatment workshop, ...

Shandong Kaitai Shot Blasting Machinery Share Co.,

... casting; 5. Stable cleaning effect, low energy consumption, and small wear amount. Production Application Suitable for shot blasting processing of large and medium sized parts in casting and forging ...

Shandong Kaitai Shot Blasting Machinery Share Co.,

... parts): 200kg Productivity: 600~1200kg/h (gray castings) Shot blasting machine: Speed: 2930r/min Impeller diameter: φ360mm Shot blasting ...

Tongbao Surface Processing Equipment

Tongbao Surface Processing Equipment

... type stone shot blasting machine,Marble shot blasting equipment Marble shot blasting equipment is generally used ...

Tongbao Surface Processing Equipment

... unloaded or loaded and raised again for introduction into the blasting system via two parallel chains. It is driven by a 0,55 kW gearmotor, operated manually by using up/down buttons Existing blasting ...

RUMP STRAHLANLAGEN GmbH & Co. KG

Machines of this type are suitable for derusting and descaling rolled steel products, such as sheets and profiles, or constructions in continuous flow operation, for removing paint ash from paint skids after pyrolysis ...

RUMP STRAHLANLAGEN GmbH & Co. KG

For shotblasting of profile constructions and other components and also for sweeping galvanized workpieces in continuous operation by means of blast wheel technology. Attachment occurs on crossbars of a manual overhead rail system, ...

RUMP STRAHLANLAGEN GmbH & Co. KG

... or smaller profiles, whereas the 8 wheel version is mainly recommended for blasting profiles. Shot Blast Cabinet As with all Wheelabrator roller conveyors the shot ...

Wheelabrator

... BEHRINGER have allied their competencies in order to provide turnkey installations that combine machining, sawing and shot blasting equipment. The combination of Partners for Steel (P4S) know how ...

Continuous blasting – Excellent, highly automated processing The selected blasting medium is directed towards your workpieces at high speed using blast wheels. This ensures high blasting ...

... overhead conveyor blast machine has been designed to treat medium/large workpieces handled by an overhead conveyor consisting in a monorail, bi-rail or hoist system, or by means of bogies. The blast ...

TURBOTECNICA

Compact shot blasting system for cleaning profiles and tubes Workspace [mm]: 600 x 300 and Number of Turbines: 4 Suitable for a throughput up to 7,500 tons a year BENEFITS AT A GLANCE Suitable ...

KALTENBACH

... Upper Air Wash Optional Medium Size Air Wash Yes Automatic Shot Adder Yes Elevator Jam Shutdown Yes Parts Sensor Optional Shot Hopper with High/Low Shot ...

LS Industries

... with a wide range of blast media, including plastics, vegetable matter, glass bead and alumina. Chilled iron grit and steel shot may also be used in pressure-fed systems. At the end of each timed cycle, the drum continues ...

VIXEN

... remove rust/corrosion etc. as a part of surface preparation before subsequent treatment. Synco has designed an Automatic Blasting Machine for External Cleaning of Metallic Rods/Pipes featured with Roller ...

Automatic machining equipment that performs high-precision cleaning and surface treatment of cutting tools, and R-honing and such of cutting edges. This is a one-workpiece-at-a-time processing method in which workpieces ...

BCT Drum Blasts have become the most popular option for tumbling parts, in many cases replacing traditional flighted tumble blast equipment and offering substantially reduced maintenance costs, which equates to less downtime. The BCT ...

Blast Cleaning Technologies

ADVANTAGES OF THIS BLAST MACHINE * Electrically height adjustable range up to 300 mm * Optional available with a tumble basket for bulk material * Optional available with a second Reclaimsystem for ...

MHG Strahlanlagen GmbH

... amount of shot blasting, high ejection speed of the international advanced cantilever centrifugal blasting machine, can significantly improve the clean-up ...

Qingdao Ted Machinery

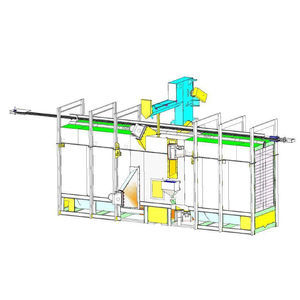

Automatic painting and shotblasting plant for silos composed of: automatic shotblasting machine, metallization booth, automatic painting booth, baking oven, chamber of control.

Steel tube wall shot-blasting machine applies to large and medium-sized steel tube outside wall surface treatment and strengthening. After cleaning, the wall surface appears steel silver ...

... through the shot blasting machine on a roller conveyor. Blasting wheels are made from wear-resistant materials with power from 7.5 to 15 kW, providing efficient shot ...

Gostol TST

Viking Chain Mesh Belt Blaster With an 18” by 18” opening this flow through unit can blast a variety of smaller parts as well as larger parts, including castings, forgings, and weldments.

Viking Blast Systems

... PLC control is fitted to make the machine operation as simple as possible. This machine is ideal for the general fabricator and can be used a section blasting machine, ...

Steelex International

Your suggestions for improvement:

A shot blasting machine is used in a closed circuit for the surface treatment of cast or forged metal products. It projects tiny abrasive particles of different shapes at high speed against a metal product to clean or confer particular characteristics to its surface.

ApplicationsThese machines are used primarily in metallurgy to strip and deburr fabricated metal products.

TechnologiesThe essential element of a the machine is its particle projection system. The most common type is a turbine using centrifugal force to project a stream of tiny abrasive particles entering at the center of the turbine. The blasting chamber is closed, with a particle recovery system. Machines differ in the method used to introduce products to be treated (hook, conveyor, rotary table, etc.)

How to chooseChoice of shot blasting machine will depend on the size and shape of the products to be treated, and whether operation will be continuous or batch. If only one side of an object is to be treated, a conveyor belt feed can be used. However, if multiple sides require treatment, a hook suspension system is more appropriate.

- Inexpensive

- Easy operation

- Allows batch treatment

- Unsuitable for fragile products

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining