- Industrial machines and equipment >

- Heat Exchanger and Refrigeration >

- Cooler for the food industry

Coolers for the food industry

Power: 1,125, 1,700 W

Maximum temperature: 2 °C - 3 °C

Flow rate: 40 l/h - 450 l/h

... optimal cooling capacity is reached. The ice water chillers are equipped with a digital Ice Mass Sensor (IMS) allowing optimum control over the accumulation of ice and maximum continuity. The water chillers ...

Baktec

COOLING SLABS Specifications Stainless steel frame and cladding Cooled by evaporators situated directly under the belt using freon as the cooling agent Independently regulated functions Available with covering ...

MORCOS Egyptian Engineering Company

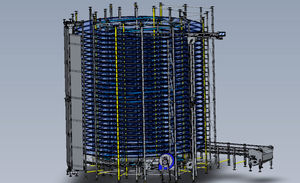

... come in different model types, such as tunnel coolers, rack coolers and spiral coolers air conditioning, to suit the product and plant. All types are equipped with an ambient and chilled ...

... flow over the entire surface, the grain is uniformly cooled and transported through the cooler. Various setting options ensure optimum adaptation of the cooling process to the input product. The interior ...

The countercurrent cooler is a highly efficient cooling system for your mixed feed pelleting process. The homogeneous cooling and gentle discharge deliver high-quality pellets, ready for safe transportation ...

industrial cooler

More than 1,000 belt units (coolers and driers) made by KAHL are in operation worldwide and work in different sectors. Before you decide on a cooler, you have the opportunity to perform a belt cooler ...

Maximum temperature: 16 °C

... ensures optimal and correct cooling of your products thanks to conditioned air. OVERVIEW • Ensures cooling process with the help of air conditioning • Direct transfer to the packaging conveyor • ...

With the vacuum technology, you can manufacture and deliver bread, rolls and pastry as part-baked products. Food retailers can also be supplied with part-baked products for sale to consumers in a quality that was not ...

Consistent quality throughout your production The quality of your products, cost-efficient heating and ease of use are factors that we focus on when it comes to recooling induction systems. With our cooling water recoolers you can ...

Power: 1,730 W - 6,260 W

The new type of evaporator allows the use of an environmental safe cooling mean. The weldded cooling body with a small volume needs a smaller quantity of cooling mean and it is easier to maintain. Automatic control of ...

Maximum temperature: 16 °C

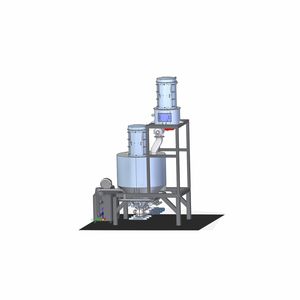

•Ranges from 30°C in the silo to 14°C in the mixer. •Guarantees even temperature of dough throughout the year. •Avoids adding ice. •Improves mixing. •Low operating costs without the need for CO2. APPLICATIONS Maintains a uniform ...

Power: 25.7, 9.45, 19, 5.81 kW

Maximum temperature: -15, -10 °C

Flow rate: 48 l/min - 181 l/min

Chiller can be used in the Complete Egg Processing Line. For the needs of the pasteurizers, every chiller must come with OPZL option (for cooling up to -15℃) How it works: In the cooling section, ...

Maximum temperature: -10 °C - 31 °C

Pressure: 100,000 Pa

First in the industry! Granule powder of food raw materials are cooled without using gas or liquid to act as a heat medium. Granule powders such as flour and starch are cooled rapidly to achieve more ...

... diameter can be equipped with an air boost system to keep the raw material in motion and provide improved chilling. B’Logic® Process Navigator flow – Tank is our dedicated software solution for performance monitoring ...

The Cabinplant water chiller is of the Baudelot (falling film) type. Water flows uniformly from a common overhead distribution trough over both sides of the vertical stainless steel plates. The water flows in a thin film ...

Power: 800 W - 5,500 W

Flow rate: 60 l/h - 500 l/h

FRIO instant water chillers exploit a system with solid storage eliminates any possibility to contaminate cooled water with Freon and lubricating oil leaking from breaking in the refrigerating circuit, and so conformed ...

Maximum temperature: 40 °F - 200 °F

Lyco has revolutionized cooling particulate food items with a new design called Easy-Flow™. Traditionally certain pasta product took 12 minutes to cook, but they could be cooled to 40F in 6 minutes,This machine is made ...

Lyco Manufacturing, Inc.

... Rotary Cooler from Hughes Equipment will stop the heating process in foods that have been blanched or cooked as part of a food processing flow. This unit works well for ...

The hydro-cooler consists of a stainless steel water tank, a cooling tank and a chain conveyor belt with specially perforated carriers. On the product infeed side, a water buffer with pump is mounted. On the product ...

Power: 0.75 W

Flow rate: 0.6 m³/h

Pressure: 3 bar

The machine is suitable for chilling/washing of red offal, using a rotating drum inside a tank tilting. It is 'made of stainless steel. Unless otherwise requested, comes complete with electrical panel wired with stainless steel cabinet, ...

An industrial chiller can be built into a production line to supply chilled water to processing machines that require it. Purchase from partner company. Installation by Constructie Bruynooghe. ...

Constructie Bruynooghe N.V.

Operation takes place continuously on conveyor belts of different designs, adapted to the container shapes and dimensions to be processed. To cool the containers, water (eg well water or ice water) is circulated countercurrently to ...

Power: 1.07 kW - 4.8 kW

Maximum temperature: 3 °C - 18 °C

Flow rate: 80 l/h - 500 l/h

... temperature from +18°C to +3°C, to be used in mixings. Flow indicator and quantity indicator have graduated scales. Water chiller with stainless steel AISI 304 structure. Internal tank thermally insulated by polyurethane ...

Cool down the produce before storage. For instant cooling of root crops Skals Machinery A/S has developed a new flatbed Hydrocooler. With an automatic swivelling feeder belt, the root crops are laid out in a 300 mm thick layer on a ...

Gentle and consistent product cooling The Thomas L. Green Forced Air Ambient Cooling Conveyor significantly reduces the internal heat of products immediately after they exit the baking chamber. Our cutting-edge equipment optimizes ...

... impacting leavening times and creating unevenness in the finished product. Cooling agents not only add unnecessary costs to your process but lead to instant decreases and unstable temperatures through time. The progressive ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining