- Food industry >

- Other Food Machinery >

- Deaerator

Deaerators

... products) are directly after cutting immersed into light solution of antioxidants, and from there transported by elevator to deaerator, it is lasting max 10-15 sec.

... quality and affordable deaerator, we will help you make the right choice, select and calculate the deaerator so that your company will get the best price / quality ratio. As a manufacturer, we offer the ...

The device described in the text is a package-type technological device that utilizes the principle of gas separation under vacuum to remove dissolved gases in water from heating, cooling, and industrial process installations. The presence ...

Tanpera

... reliability and durability with its Atmospheric Series of deaerators. Designed to increase the longevity of boiler piping systems by reducing O2 and CO2 content in boiler water, Seller’s pressurized deaerators ...

Designed to reduce the dissolved air in water used on the preparation of drinks, syrups, juices and other products. Double deaeration technology by using deaeration double chamber on vacuum atmosphere. No consumption of CO2. Low ...

Mud logging Ex proof Degasser Mud logging Ex proof Degasser for oil and gas exploration. CL-DT electric degasser has two types: CL-DT11 (220V motor) and CL-DT12 (380V motor). It is ...

Apparatus is including thermostatic circulator, necessary tubing and glass plunger. Analytical balance with special connection is included for plunger hanging. This test method measures the time for the entrained air content to fall ...

The Sentry W7950 sparger assembly is used to prepare a sample for taking a degassed cation conductivity measurement. After the sample has been cooled and the pressure controlled, it enters the sparger assembly. It passes through a ...

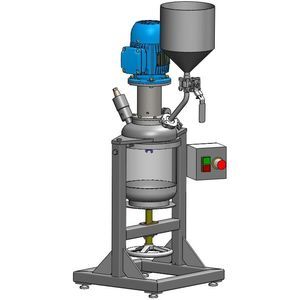

The De-aerator type VD-05 is designed for laboratory batch production. The VD-05 is a highly efficient de-aerator. The product is automatically sucked into the vacuum vessel and has to pass a special ...

... off and variable speed pumping The TrayMaster deaerator is a pressurized, low-maintenance system designed to remove dissolved oxygen in boiler feedwater and eliminate carbon dioxide. This deaerator ...

Cleaver-Brooks

benefits of Somex degasser Control over operating parameters Control over sample temperature Efficient typically 3 minute cycle time Ramp to control foaming Somex degassers have been validated and are ...

Some fluids contain air or other gaseous impurities that cause inaccuracies during dispensing. A degasser is designed to remove the air or gaseous impurities from the fluid to help improve your end results. This unit ...

WEDEG Fully Automatic Deaerators (Thermal Gas Separator) -WENTA fully automatic deaerators totally isolated with rockwool. Its outside is coated with galvanize or stainless steel on demand. Thus, the ...

... Deaeration During continuous deaerating process of liquid to high viscosity products, a dynamic process Mechstar® Vacuum Deaerator offers a highly efficient, cost-effective solution. This can be tailored to individual ...

Energest® Thermal Deaerator are desgined to operate in two complementary stages, one of mechanical spraying and the other of hydrostatic spraying, in counter current with steam, which allows to obtain a very high efficiency ...

Degasor tanks are used for the separation of O2 and CO2 gases which are in the water of the steam boiler and cause melting, puncture (corrosion). It is produced in compliance with the required standards, pressure vessel directives and ...

Packaged Deaerator systems, 5,000 to 200,000 PPH. Conditions feedwater to 0% CO2 and .005cc/liter of oxygen. The HURST OXY-MISER deaerating boiler feedwater system eliminates the need of expensive oxygen scavenger chemicals ...

The -4H- Debubbler removes unwanted bubbles from your process waters. There are different versions in terms of size, volume, and material of the ‑4H‑debubbler available. Of course we can customize our ‑4H‑debubbler to fit your demands. The ...

The Vacuum De-aeration Vessel or Vacuum Flash Vessel is used to receive the cooked product from the RotaTherm® Direct Steam Injection Cooker and 'flash' cool the product to the required filling temperature and remove entrained air from ...

The plant is made up of a vacuum operating tank in which the product to be deaerated is sent. Thanks to a partial auto-evaporation, automatically controlled, the air contained in the products goes out. The plant is completed with ...

Characteristics of Vacuum Degasser by Kosun: 1. Self-priming device enables it to pump drilling fluids without centrifugal pump. 2. Corrosion is eliminated and cost of repairing as well as maintenance reduced. 3. The ...

The cationic conductivity degasser DG-105 is a device designed to obtain the conductivity value of a sample, eliminating the contribution to the same of the possible gases that may be dissolved. After boiling the sample, ...

MANVIA

Sarralle VD-VOD units can be engineered to operate with steam injectors or dry mechanical vacuum pumps to achieve deep vacuum with lowest energy consumption in shortest pump down time. Whereas steam ejector vacuum pumps offers a simple, ...

The Degasser, developed by Eurowater, is specifically built suitable for pre-treatment of feed water for steam boilers. It can be insulated with mineral wool and covered with aluminium plates. The standard unit is specially constructed ...

... ensures equipment’s longevity, maintains steam quality and reduces operating costs. Pressurised Thermal Deaerator A pressurised thermal deaerator, operating at circa 0.3 barg allows the temperature ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining