- Machine-tools >

- Finishing Machine >

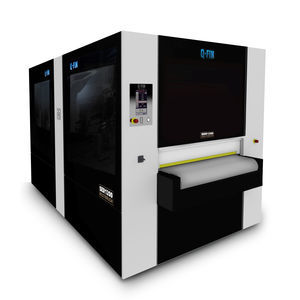

- Deburring finishing machine

Deburring finishing machines

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Power: 0.75, 2.2 kW

The ASM centrifugal machines are ideal for small parts. With higher processing intensity, they deburr 10-20 times faster than vibratory finishing machines. The centrifugal system can be ...

Machines for manual finishing Double working group with independent motors Main Features: - A single operator - Double working group, each driven by an independent motor with high power - Possibility ...

Machines for manual finishing with double working group and 2 independent motors Main features: - It can be used by a single operator or by two operators simultaneously - Double working group, each driven ...

Power: 1.2 kVA - 10 kVA

... disc finishing machines can be used for any application that requires a perfect surface finish to be achieved in a very short time for a variety of workpieces such as in cutting, turning, ...

OTEC Präzisionsfinish GmbH

Power: 11 kVA

... very high cost savings in terms of processing times make the DF series an extremely cost-effective solution. Drag finishing machine for workpieces. STANDARD EQUIPMENT Process container with a capacity ...

OTEC Präzisionsfinish GmbH

Power: 1.8, 0.4, 0.8, 0.9 kVA

... disc finishing machines can be used for any application that requires a perfect surface finish to be achieved in a very short time for a variety of workpieces such as in cutting, turning, ...

OTEC Präzisionsfinish GmbH

Power: 4 kW

Rotational speed: 3,000 rpm

Automatic rotary brush deburrer for finishing both ends of the tube. • Brush-holder groups adjustable orthogonally on two independent axes through flyers • Only internal, external or internal / external ...

Power: 0.75, 2.2, 5.5 kW

Rotational speed: 0 rpm - 1,500 rpm

KSM Series - Centrifugal Disc Finishing Machines The KSM Series Centrifugal Disc Finishing Machines are designed for precise deburring and polishing ...

... special maintenance. Each head is equipped with compensation wheels that adapt the position of the grinding head so that machining is always perfectly on the edge, managing the tolerances of the beam.

... the most advanced, powerful and versatile metal surface finishing equipment on the market specially designed for mass production. The new DLyte PRO500 provides high quality metal surface finishing better, ...

The 31 series deburring and finishing machine is available in a width of 450 mm and 900 mm. The machine is suitable for deburring and finishing ...

Timesavers

Power: 11, 4 kW

Rotational speed: 178, 213 rpm

TT...SM CENTRIFUGAL DISC FINISHING UNITCOMPACT AND PIVOTING Centrifugal disc finishing units from the TT...SM range have an attached screening machine and integrated hopper for abrasive ...

Walther Trowal GmbH&Co.KG

Power: 1.8 kW

... to each other and results in targeted material érosion Processing time is several times shorter comparing to Vibratory Machines reliability and durability - polyurethane lining of the working bowl is extremely wear-resistant ...

AVALON

Power: 32 kW

Rotational speed: 0.3 rpm - 8 rpm

... mm wide. Deburring, edge rounding, Radius 2, oxide layer removal, line finish or non-directional finish. It is all programmable for the automatically adjustable operating stations. • Fastest and most ...

Power: 2.5 kW - 5 kW

... high-speed turbo tank for quick processing, ball burnishing, hard deburring tridimensional effect that can be applied on the single and double version. It is quick, solid and as a practical machine, ...

LM srl

Power: 75 kW

... itself. With the M series, WEBER has developed a machine that produces such perfect sanding patterns that nothing is left to be desired. Even fully automatically if necessary. The WEBER M produces a surface finish ...

Power: 0.75, 1.5, 3 kW

Rotational speed: 0 rpm - 240 rpm

DESCRIPTION Centrifugal surface finishing machine is particulary effective when cleaning complex work pieces and small metal pieces which require long processing time, as well as tires, plastics, rubber, ...

High Energy Centrifugal Barrel Finishing Machines – Harperizing Systems High energy centrifugal finishing machines also known as harperizer systems are the fastest and ...

Power: 0.75, 2.3, 2.2 kW

Rotational speed: 380, 400, 450 rpm

Power: 3.7 kW

Rotational speed: 0 rpm - 335 rpm

Mighty-Mild® The high-gravitational barrel finishing machine - Only Tipton's finishers have 30G mass finishing capability ✓Features Mighty-Mild® has improved on the conventional ...

Tipton Corp.

Power: 7.5 ch - 20 ch

... brushes, singly, in groups or in combinations. They are used for a wide variety of operations such as stock removal, fine finishing, deburring, scale or oxide removal on a wide variety of both ferrous ...

CNC rotary transfer machine for deburring and micro-finishing gears, with robotized loading and unloading.

AUTOPULIT

Power: 4 kW

Rotational speed: 300 rpm - 2,000 rpm

... variety of processes can be realized with one machine such as grinding, polishing or deburring TECHNICAL DATA Robust steel construction designed for continuous operation to accommodate up to 6 machining ...

Power: 2.2, 1.2 kW

Rotational speed: 1,500 rpm

The grinding-/brushing station FINISHSTATION is being used to grind and polish edges and surfaces as well as for deburring operations. The wheels are mounted so that they are in one axis radially compliant. The brush ...

Vixen are a global leader in the design and manufacture of surface treatment solutions Wet blasting solutions Washing and degreasing solutions including tank lines Dry blasting cabinets We have applications for many industries ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining