- Packing - Handling - Logistics >

- Packing and Packaging >

- Electric shrink tunnel

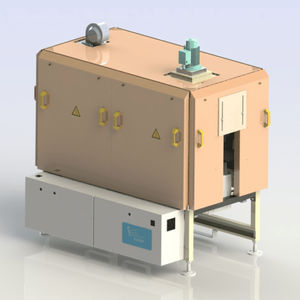

Electric shrink tunnels

Power: 10 kW

... shrinking suitable also for delicate products, and no mechanical stress on the sleeve. Suitable for lots of industries. Your tunnel come with an automatically set temperature. Stainless steel available in option.

Stainless steel structure, Six Leister Tunnel. Suitable for shrinkage of Sleeve labels made of different materials and thickness (from 35 to 60 micron at low speed). Suitable for cosmetic container with small dimensions ...

Power: 7, 8 kW

TUNNEL 50 e 70 are a master piece in Minipack-Torre shrink tunnel devices. Now on the market with up to dated solutions to pack with maximum efficacy the most different kind of shrinking ...

MINIPACK - TORRE

This Electric heat tunnel is used to shrink sleeve labels onto bottles and products using a very controlled and adjustable method. Adjustments to the heating pattern can be done while ...

Speed: 15, 20 m/min

Power: 12, 21 kW

Using our high-performance and energy-efficient shrink tunnels your products can be shrunk rapidly, effectively, and safely by means of hot air circulation. Our shrink tunnels ...

ALPHA-PACKEUROPE / SCELLINOX

Speed: 2 m/min - 14.5 m/min

Power: 8,000 W

... Polyethylene : up to 50 µ Technical data : • Single-chamber shrink tunnel • FLXMOD® control system equipped with: • Alphanumeric LCD control panel provided with electronic board • ...

Smipack S.p.A.

Speed: 0 m/s - 0.9 m/s

... Brand XT tunnels employ a unique chamber design and airflow system that allow the operator complete control of the shrink process, whether the product and film require a gentle air flow or greater circulation ...

Power: 3,000 W

... manufactures a Tamper-Evident Shrink Band Tunnel. This add-on is flexible and convenient, and works hand-in-hand with your hand applied sleeves, or machine applied sleeves for quality results. The ...

For certain shrink sleeve applications, the electric shrink sleeve tunnel is the perfect solution. This is a compact edition, equipped with individual hot air blowers. ...

Power: 16 kW

... 3 Ph, 50-60 Hz. Heating Power : 16 kw Average Power : 8 kw Total Power : 16 kw Motor Power of Carrier Band : 1/3 hp Sealing Tunnel ...

ÖZÇAĞDAŞ MAKİNA İNŞ. GIDA SAN. VE TİC. LTD. ŞTİ.

Power: 22 kW

... feet, the possibility of applying castor wheels with brakes. Power supply: 380 V 3P + N + E Max consumption: 22 kw Max temperature: 250 ° Thermal protection: it External dimensions tunnel: 1200 mm. ...

F.C.L. Engineering

Speed: 30 mm/min - 400 mm/min

Power: 30 kW - 100 kW

Packaging with shrink-wrapping film is a low-cost option for protecting products from moisture, soiling and damage during transport. The KUPER KST is a large capacity shrink tunnel in ...

... that could be set freely to distinctive steam rates, heights and angle, the Thermopoint makes the most astounding quality shrink finish. With a 7" wide x 15" tall maximum container size, a 80 PSI maximum steam input ...

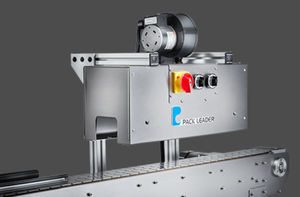

Electric sleeve tunnels are used for sealing the body sleeve labels on the bottles by heat produced by electric energy.The sleeve labels are applied manually or by a sleeve machine (applicator).

Speed: 300 mm/min - 2,100 mm/min

... tunnel intended for processing the heat shrink tubing to insulate or cover small cable bundles. The shrink tunnel has the capacity to be used in an individual workstation.

Power: 9 kW

... handling and the machine can be integrated into a small shrink line. Hygienic design and optimized technology. The first manual shrink tank in the WEBOMATIC CleanDesign® processes all types of shrink ...

WEBOMATIC

ST 170: stainless steel construction. The automatic transport of the product in and out of the shrink tunnel is controlled by a photocell. - Water temperature is adjusted with a thermostat. - ...

Power: 8,000 W

The infrared heating tunnel is widely applied for heating heat shrink tubing, PVC, POF, PET, and PP products. • The infrared heating machine works fully automatically, JWD-4020 is suitable for heating ...

Speed: 70 m/min

Power: 9, 18 kW

... particular. The article is moistened with an electronical high-pressure steam generator. Shrinkage follows in a downstream tunnel with hot air feeding from above and below. The main advantage of this process is low energy ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining