- Production Machines >

- Plastics Processing >

- Extrusion screen changer

Extrusion screen changers

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

... specifications, always have a suitable for your requirements Manual screen changer series: ●Extruder screw can draw from the screen changer directly, it is convenient ...

... cavity (25%) in backflush position Screen Change - 3 screen cavities (75%) in the process, 1 screen cavity (25%) in screen change position Reservoir Filling - 4 screen ...

Nordson Polymer Processing Systems

... process pressure with no line shutdowns bringing maximum efficiency to your extrusion operation. The BKG® NorCon™ K-SWE is our most versatile melt filter, suitable for plastics extrusion, compounding, ...

Nordson Polymer Processing Systems

... for extrusion, batch, masterbatch, and compounding processes. The BKG® NorCon™ D-SWE is a discontinuous melt filter to mostly process virgin material. It is also used for protection filtration purposes installed ...

Nordson Polymer Processing Systems

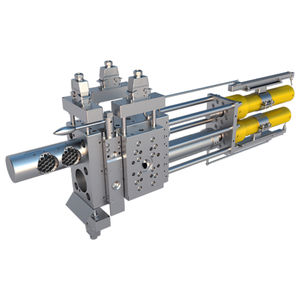

... The BKG® NorCon™ LK-SWE is based on a proven double-piston design with two oval-shaped screen cavities increasing the available filtration area. During screen change, only one of the pistons is moved ...

Nordson Polymer Processing Systems

... a short residence time of the melt Increase Convenience Compact extruder interface Easy exchange of the screw without the need to dismount the melt filter thanks to the extruder screw pull-through ...

Nordson Polymer Processing Systems

... also used for protection filtration purposes installed directly behind the extruder preventing damage to the downstream equipment. The BKG® NorCon™ LD-SWE has oval-shaped screen cavities providing ...

Nordson Polymer Processing Systems

... throughputs. The BKG® POLY is THE melt filter to go with whenever virgin polymer melt needs to be prepared for direct extrusion of films, fibers, straps, profiles, sheets, or tubes at large-scale volumes up to 45,000 ...

Nordson Polymer Processing Systems

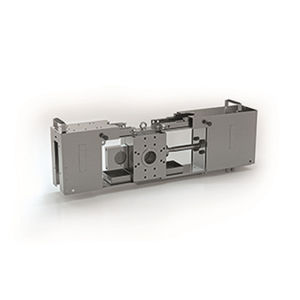

The flow optimized new version of MAAG´s FSC hydraulic and manual screen changers assist operators of plastic extrusion lines in achieving a reduced equipment footprint, reduced residence ...

Maag Germany GmbH

MAAG backflush screen changers are based on the proven double-piston design which operates without any mechanical seals and is equipped with four screen cavities. This design is used ...

Maag Germany GmbH

FSC screen changers from Maag are equipped with a pressure-adaptive sealing system as a standard. Thanks to this sealing system, the required sealing forces are adjusted to the actual melt pressure automatically. ...

Maag Germany GmbH

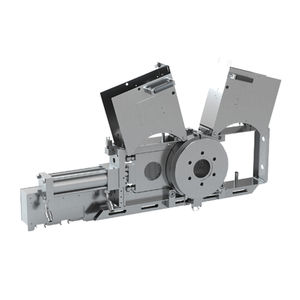

MAAG’s CSC-C large scale screen changer with candle filter elements is the right choice if short melt residence time, small footprint and a simplified candle change are required. Depending on the polymer ...

Maag Germany GmbH

Discontinuous DSC screen changers from MAAG with their robust and leak-free operation meet highest quality standards with respect to melt filtration. Due to their constantly improved functionality continuous ...

Maag Germany GmbH

Manual screen changers from Maag have been the first choice of cost-effective filtration systems in extrusion lines for many years. Starting at size 45, the manual screen ...

Maag Germany GmbH

... threshold, the screen change process starts. The two valves close the channel, the plate is moved of few millimeters to let the screen free to advance and replace the dirty section with a clean and fresh ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining