- Packing - Handling - Logistics >

- Conveying >

- Feeder

Feeders

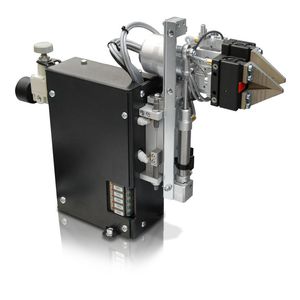

The SLD 4100 double gripper module gathers two single wires with outer diameters from 1 - 4 mm (0.039 - 0.157”) in the proper orientation allowing the swivel arm gripper to collect them. The wires are then moved to a separate station ...

Specifications: Stroke rate: max. 1,200 strokes/min (20 mm feed pitch) Feeding speed: max. 3.2 m/s Feeding force: 1,000 N Feeding accuracy: ± 0.02 mm Hydraulic ...

... customizable touch screen HMI integrated with a low rpm, AC, Brushless Servo, a PID control loop is established to control the ICV feeding our patented CentriFlow Meter. For precise measurement and control, an Integral ...

The CentriFeeder line of feeders provides accurate, real-time flow measurement, as well as near perfect control of flow rate and total. For blending applications, control the flow rate of an individual ingredient, or ...

... materials to discharge from trucks and uniform feeding of the processing line. It is usable for many types of vegetables such as corn, green bean, green peas, spinach, broccoli, pepper etc. Uniform feeding ...

... Replace 8-10 workers at your existing pocket-chain machines. The fish auto feeder is specifically designed for fish cutting machines with pocket conveyors. The auto feeder makes the HGT process faster ...

COLUMN SELF-POWERED DRIVING STATION - tilting drawer screws positioning Max stroke - mm - 40 Length - mm - 595 Width - mm - 320 Height - mm - 1130 Base support - mm - 280 X 215 Weight - Kg - 35

SCREW FEEDERS - from bench with vibrating screws positioning

SCREW FEEDERS - from bench with tilting drawer screws positioning

... possibility to change the arc feeding width for any kind of mould. Control panel, placed on the electric cabinet, consists of an operator interface and a cams positioner. The operator interface allows the setting of: ...

... movement is determined by the angle of the springs. Vibratory feeders have been extremely used for automatic feeding of small to large and differently shaped industrial parts.Vibratory feeders ...

... be formed. The following features characterize blank feed systems: Pick-up and transfer of one/ several blank(s) from robot or feed systems Linear axes with one/ several feeding ...

Simplify your stock control by labelling and coding your cases off-line! The TR-1000 Casefeeder is designed to feed flat, unerected corrugated cases for coding with inkjet, labelling, or print & apply. The case is presented ...

ERGA vibrating feeders are used for bulk and lumpy material discharge from hoppers or uniform and dosed feeding to components of processing plants and lines. - Wide range of designs and applications: ERGA ...

Easy linen feeding Easy of use The “IFE” series feeder facilitates and speeds up the manual operation of inserting the linen. It can be used both for small items (pillowcases and napkins) and for ...

... Pharmalift provides a large capacity bulk hopper at operator level that will feed on demand to the filling machine. Touch-screen / PLC control system allows the vibratory feed speed to be optimized ...

Application: Vegetables Machinery, Carrots, Potatoes, Onions Equipment category: Infeed and dosing, Feeding Suitable for: carrots, potatoes, green beans, flat onions, cucumbers, turnips, all vegetables, roots, shallot, ...

... control with the same PLC – Feeding with an angle to the feeder – The conveyor gives an opportunity loading the materials more – The operator can control multiple feeders due to the ...

Maripak Packaging Ltd.

... the crushing plant to receive the raw material. They are usually followed by a vibrating feeder to continuously feed the material to the crusher. Vibrating feeders are very sturdy shockproof, ...

Boratas Machinery

... They are usually followed by a vibrating feeder and in some cases by a grizzly screen. The hoppers are very important because they ensure the loading of ail the materials to be crushed. The vibrating feeder, ...

Boratas Machinery

... the crushing plant. They are usually followed by a vibrating feeder. The hoppers are very important because they ensure the loading of ail the materials to be crushed. The vibrating feeder, as its ...

Boratas Machinery

Features : 12NC2 with Infeed grinding automation one lamping with vibration hooper Dressing way: X axis for Grinding wheel dressing infeeding plus hydraulic cylinder moving. The Pneumatic Tools size tolerance is below 0.01mm. The whole ...

S-TYPE Ltd., Co.

The sized tolerance is below 0.01mm. The whole size precision is below 0.002mm. The reservation for grinding is 0.15mm. Under the 0.01 mm size control, it can have 100 pcs performance to achieve the standard After auto dressing and ...

S-TYPE Ltd., Co.

S-TYPE Ltd., Co.

Our linear vibratory feeders are designed to actuate a variety of products and used with a variety of processing lines and packaging machines. For example our V0.5 linear vibrator supports precision handling for products ...

The Electromagnetic Feeder, manufactured by Tarnos, is specifically designed for feeding a broad variety of bulk material, from storage hoppers or silos to belt conveyors, mills, dryers, mixers applications. ...

TARNOS

The RF series manufactured by Tarnos, is an electromechanical vibratory feeder that runs on a 90 - 650 t/h. It features a low power electric motor that is capable of a stable operation. This device also provides a smooth ...

TARNOS

TARNOS electromechanical feeders are designed in such a way that they achieve high altitude and has a very high flow capacity along with adherent, moist and sticky applications. This kind of vibrator is divided into two ...

TARNOS

The cost-effective Direct Drive Feeder™ (and conveyor) meets all the process requirements of bulk handling industries and can be configured horizontally or inclined to fit your exact floor space. Drive mechanism The ...

G.P.A. pneumatic feeders, as all G.P.A. pneumatic equipments, completely match all the technical requirements of the EEC standards to day in force, particularly the "machinery" directive and the EMC directive, in some ...

G.P.A. ITALIANA

... materials. (2) The axial stability of feeding is ensured by using the linkage of double cylinders on both sides. ③ Corrosion-resistant design. (4) meet the requirements of 90-120 liter turnover box. ⑤ The ...

... steps within a compact, space-saving unit. The universal feeder system is a combination of our progressive cavity pump (CC series) with the RotaCut RCX cutter. Optionally the solid matter feeder can be ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining