- Production Machines >

- Other Manufacturing Equipment >

- Forging

Forging

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

The Boën forge was founded at the end of the 19th century with the creation of Establishments Moizieux. Its know-how has developed over the course of technological developments in response to the industrial needs of each era. Our ...

S.B.S. GROUPE GENOYER

The Boën forge was founded at the end of the 19th century with the creation of Establishments Moizieux. Its know-how has developed over the course of technological developments in response to the industrial needs of each era. Our ...

S.B.S. GROUPE GENOYER

The Boën forge was founded at the end of the 19th century with the creation of Establishments Moizieux. Its know-how has developed over the course of technological developments in response to the industrial needs of each era. Our ...

S.B.S. GROUPE GENOYER

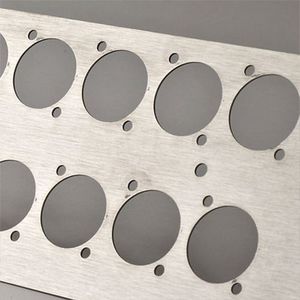

Our high-quality custom copper busbars are designed to meet your electrical conduction needs. Made from premium copper materials, they ensure excellent electrical conductivity and long-term durability. Each busbar is precision-machined ...

HLC METAL PARTS LTD

... we are qualified with IATF16949&ISO13485, which is the higher quality management system. • Material: Brass • Process: Stamping • Application: Electrical switches •Requirements: No Burrs, Scratches, Dents, Pits •Packing: ...

HLC METAL PARTS LTD

Custom Electrical Stamping Contact terminals. HLC METAL PARTS LTD is a professional manufacturer of metal parts. we are qualified with IATF16949&ISO13485, which is the higher quality management system. •Requirements: ...

HLC METAL PARTS LTD

In close collaboration with the customer, solution-oriented process stages are developed and optimally adapted to the customer's individual requirements. By this process, the HEICO group is able to replace castings and turned parts with ...

... moulds, which have the negative shape of the object to be obtained while the metal is heated by means of gas furnaces. Hot forging guarantees particular mechanical characteristics such as greater resistance to strain, ...

Hot stamping is an ancient technique for modeling metals by heating and plastic transformation of raw pieces into special toolings. Compared to any other casting technique, the choice of this technology is the high ...

Mecachrome's sheet metal working and boiler making activities offer a full range of production of aerostructure elements based on know-how in product industrialization, manufacture and assembly of sheet metal and boiler making parts and ...

Mecachrome

Hot die forging consists in shaping blanks, after prior heating, by pressing them between two blocks (the dies) with moulds of the preliminary or the near-net shape of the product to be manufactured. The hot forging ...

Groupe SIFCOR

... The availability of ring-rolling mills, hydraulic presses, manipulators, forging furnaces and a wide range of complementary equipment gives us the ability to obtain rough-forgings with a shape already ...

Ringmill S.p.A.

Nine production lines with presses between 500 and 2,500 tons, fed by four cold shearing lines: this system is active on two shifts, capable of punctually and flexibly meeting the most diverse range of needs. All lines are equipped with ...

FACEM

... process... Discover all our technologies! Our expertise: Stamping of consolidated thermoplastic composite blanks Thermo-compression of thermoplastic composite fabrics Hybrid Process Stamping or ...

DEDIENNE MULTIPLASTURGY® GROUP

Matson Metal is a supplier of OEM valve castings with machining service in China. With 20 years' experiences in this industry, we focus on and have advantages in the following aspects: engineering - Review and evaluate your drawings ...

Hebei Matson Metal Tech Co., Ltd.

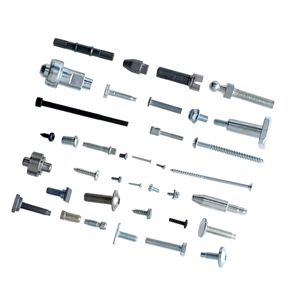

For the manufacture of metal parts, screws and rivets, ETMA has the capacity to work wires with a diameter between 1.5mm and 12mm in double blow and multi slide horizontal presses and in a variety of materials. We can finish the forged ...

ETMA METAL PARTS

CLOSE-DIE FORGING AND HOT EXTRUSION Manoir Industries is one of the european leaders in forging with heavy stamping and hot extrusion, specialising in the production of complex forged ...

... only some of them. Stamping consists on compressing a specific metal between two moulds. There are two types of stamping: the progressive stamping and printing by percussion. In progressive type, compression ...

GESTION DE COMPRAS

Nous produisons des composants à partir de feuillard de largeur jusqu'à 600mm et d'épaisseur 0.5 - 4 mm. Presse mécaniques de 30 à 500 t

The Integration of all our equipment at our Méréville site enables us to offer you carefully-made manufactured items within exceptional short lead-times. We produce rough forged, shot-blasted or rough-machined parts which match up ...

L'UNION DES FORGERONS

... production requests are then met on furnace and electro-upsetting lines, ranging from 1.5 up to 25 kg. Why hot press forging? Forging and CNC machining are consequent activities. In order to meet ...

We manufacture parts by cold metal stamping and drawing, up to 160 tons, with all types of metals, steel, aluminum, stainless steel...

YEGLES INNOVATION TECHNOLOGIES

Stamping is very similar to punching, except the material is not cut. The die is shaped to make a raised portion of material rather than penetrating.

... pressing force of up to 50 tonnes and 950 bpm, the machine types for micro stamping / progressive die stamping of customized progressive die stamping parts can perform precision stamping ...

Mekoprint A/S

The main facility is punching machine, which brand are Seyi from Taiwan and Yangli from China.The punching tonnage is 63 t to 125t.

Stamping of metal parts. We own presses ranging from 10 to 100 tons. Production of stamping tools, production of stamped parts according to a sample, drawing or sketch. Production of various parts - blades, ...

Metal sheets components are often used as support (electronics, lighting, equipments, machines) and are not part of our customers high value core competencies. – Parts in all available materials : Stainless steel, aluminium, CRS, aluzinc, ...

Laser cutting in combination with stamping combines the advantages of both techniques. This combination of laser cutting and stamping is ideal for producing particularly demanding sheet-metal products. COMPETENCY Our ...

LEMAN Industrie’s expertise in the field of metal processing is founded on forty years of know-how and its original core business: metal stamping. Its command of metalworking procedures related to cutting (stamping, bending, sheet metal ...

LEMAN INDUSTRIE

Your suggestions for improvement:

the best suppliers

Subscribe to our newsletter

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining