- Power Transmission - Mechanical components >

- Mechanical Transmission >

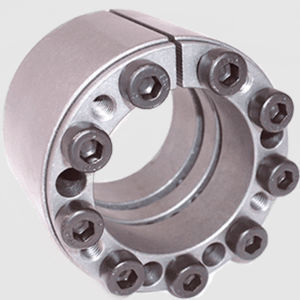

- Friction coupling

Friction couplings

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Torque: 196 Nm - 173,000 Nm

... below) are made of specially lubricated stainless steel (SUH660). These materials minimize dust and maintain a constant friction coefficient and high efficiency. ・Due to the above, no additional lubrication is necessary ...

Tsubakimoto Chain

Torque: 5 Nm - 9,900 Nm

With a lineup from small diameter shafts, it can be used for a wide range of shaft tolerances. (Other than KE-KP ) ・Designed to suit a wide range of shaft tolerances Standard models can accommodate plus shaft tolerances of servomotors, ...

Tsubakimoto Chain

Torque: 265 Nm - 27,000 Nm

Product photo Type with flange and self-centering function that has the same inner and outer diameters as the AS series. ・This Series has the same inner and outer diameters as AS Series, and is suitable when a centering guide part ...

Tsubakimoto Chain

Torque: 250 Nm - 2,270,000 Nm

These are the original type of shaft clamping elements, proven in a wide range of applications for more than 20 years. Suited to more general applications, this series provides medium torque transmission, which can be increased by mounting ...

Torque: 264 Nm - 136,500 Nm

... to locate hub and prevent axial movements, so combining good concentricity with positive axial location. The increase in friction between the cones due to axial restriction results in torque reduction of approx 20%, ...

Torque: 294 Nm - 48,200 Nm

... type RCK 70 with addition of a distance ring to prevent axial movement of the hub during clamping. Due to the additional friction between the element and hub during clamping maximum torques are reduced, but with reduction ...

... Hub materials: aluminium up to size 38/45, steel for larger sizes TYPE 6.0 • Zero backlash shaft connection under high friction torque • For Servo motor applications such as main spindle drives of tooling machines ...

Torque: 2,000 Nm

... sleeve had been heated and shrunk on. But no heat is required, and the coupling can be removed as easily as it was mounted. This powerful use of friction enables the OK coupling to ...

Torque: 0.5, 1.8, 5, 10 Nm

Rotational speed: 3,000 rpm

Double Loop Couplings with Steel Hubs The double loop coupling uses a moulded plastic element permanently swaged to steel or stainless steel hubs to give a compact design. It forms an effective two-stage ...

Torque: 0 Nm - 5,000 Nm

Rotational speed: 0 rpm - 800 rpm

Friction couplings protect motors, gearboxes or downstream machinery against overloads. The torque of the friction couplings can be adjusted as needed. Friction ...

Torque: 1,030 Nm - 2,500,000 Nm

The main function of the rigid flange coupling is the safe and backlash-free connection of two shafts by means of frictional engagement. For example between a drive shaft and a stirrer shaft. Flange couplings ...

TAS-Schäfer GmbH

Torque: 0 Nm - 800 Nm

... rotation and ultra-precise control. ■ Frictional Coupling for Large Diameters This model supports frictional coupling for larger-diameter shafts than the previous models. The Servoflex SFF coupling ...

... the drive train, these primarily include safety couplings, which are available in a wide range of designs today. With the HYGUARD® hydraulic safety coupling, the torque is transmitted exclusively via ...

Torque: 16 Nm

Rotary couplings without/with leakage recirculation Rotary couplings transfer hydraulic oil from a fixed to a rotating machine part. The assembly is done in the rotation axis of the subassembly. Depending ...

Your suggestions for improvement:

the best suppliers

Subscribe to our newsletter

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining