- Industrial machines and equipment >

- Surface Treatment >

- Galvanizing

Galvanizing

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

This Multifunctional Washer is made of high-quality iron and its surface is galvanized to enhance its corrosion resistance. The galvanized layer not only improves the durability of the washer, but also gives it a smooth appearance, suitable ...

Turning Parts, Metal Parts Manufacturer, Custom CNC machining parts. According to customer requirements, galvanized surface treatment of product raw materials •Material: Steel, Brass, Aluminum, Stainless Steel •Surface Treatment/Finishing: ...

Complementary processing techniques Thanks to the experience developed throughout the years, Fotomeccanica is able to provide additional processing techniques to complete the photo-etching process, such as high-quality galvanic plating ...

FOTOMECCANICA SRL

BIEBER Industrie has been able to grow a 21,000 m2 industrial site, in Drulingen, Alsace France. The reworking of the workshop, providing an adjustable workplace for soldering, assembly and finishing touches, allows the place to accomodate ...

Bieber Industrie

... recognizes the importance of the hot-dip galvanizing which is the most effective treatment for the protection of steel against atmospheric conditions. Thus, it has installed and operates a modern hot-dip galvanizing ...

Hot-dip galvanisation Permanent surface protection - Hot-dip galvanisation contributes to an extremely long service life. COMPETENCY Hot-dip galvanisation is still the best guarantee for permanent and effective corrosion protection. ...

... ensures additionally that the entire surface is uniformly wetted while galvanizing. Prior to that, the aqueous flux film on the steel part is dried in a drying oven. Now the actual galvanizing of the ...

Experienced companies that are closely associated with Glüpker Blechtechnologie and share our philosophy carry out industrial coating using different processes. Thanks to the great flexibility and quality of the individual procedures, ...

Glüpker Blechtechnologie GmbH

The highest corrosion protection for your steel. Hot-dip galvanising guarantees perfect all-round protection of your components. In hot-dip galvanising, the pretreated steel parts are immersed in a molten zinc liquid that is heated ...

Collini Holding AG

Hot-Dip Galvanizing or HDG is a process in which zinc bonds to steel at the molecular level to produce a four-layer corrosion-resistant finish. The first three layers are zinc-iron alloy layers that are actually harder ...

SUTOR TECHNOLOGY CO., LTD

Widely used in Electricity facilities, Elevator parts

Electrolytic galvanizing of steel parts and products: with a low layer thickness and attractive pricing Multinal Group is the right partner for electrolytic galvanizing of steel parts and products. ...

... demands of quality and service lives are crucial. Hot-dip galvanizing is a process where the item for galvanizing is cleaned of grease, oil, mill scale, rust and other impurities. Hot-dip galvanizing ...

We use zinc electroplating to add a zinc coat to materials (Zn and Zn/Ni), which serves as a base layer for further coating, or as a surface finish it gives products a more attractive appearance than in their unfinished state. In any ...

LAKUM

The zinc coating is an electroplating process with zinc metal, obtained by alkaline or acid aqueous solutions with specific additives, used for technical purposes in many applications. Features: absence of Cr +6, compliant with ...

With hot-dip galvanizing, the material to be galvanized is immersed in molten zinc. As a consequence of the mutual diffusion, a layer of differently composed zinc-iron alloy layers forms between the zinc and the steel ...

... video) and GALVA 45. THE ADVANTAGES OF CENTRIFUGATION BY GALVA UNION All the corrosion protection qualities of hot-dip galvanizing for small parts. A good quality of finish which very often makes it possible to avoid ...

GALVANISATION DE VALENCE

... . Advantages of mechanical galvanizing: Eliminate re-tapping of nuts: In hot-dip galvanizing, threads must be cut or chased after galvanizing, robbing them of protection and requiring ...

Industrial Metal Finishing

... production lines are: The first large galvanizing pot is 13.5 meters × 2.5 meters × 3.8 meters; The second medium-sized galvanizing pot is 7.5 meters × 1.8 meters × 2.2 meters; The third small ...

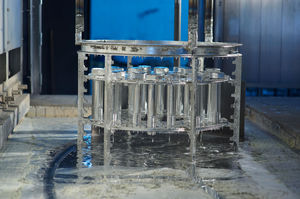

Process of electrolytic galvanizing – drum line ✔ Automatic stroke line ✔ Galvanizing of elements of diameter from 3 mm and length up to 300 mm ✔ The range of the thickness of the coating 5-15μm ✔ White ...

... machinery and so on. Surface Treatment Our surface treatment ability include : Powder coating Painting Anodizing Galvanizing Chrome Plating Electroplating Polishing Nickel Plating Passivation Enameling

Electrogalvanizing of rack objects For all kinds of machine components and technical items electrogalvanizing with varied chromating is still the most frequently-employed protection against corrosion. This process is particularly indispensable ...

... manufacture the industry’s most advanced systems for working with zinc and zinc alloys. We offer a full line of high performance galvanizing pots for coating applications, including specially-designed coating pots, pre-melting ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining