- Industrial machines and equipment >

- Furnace and Heat Treatments >

- Graphite oven

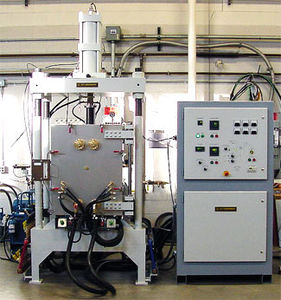

Graphite ovens

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Maximum temperature: 1,250 °C

... treatment implementations. MAIN FEATURES: / Fully automated processing / Vacuum, horizontal, double-, and triple-chamber / Graphite heating chamber / Low heat losses by increased thermal insulation / Low pressure ...

SECO/WARWICK S.A.

CVI (Chemical Vapor Infiltration) furnaces are special solutions used in the CVI process, which is a technique for producing carbon materials, such as graphite, by saturating them with carbon from the ...

SECO/WARWICK S.A.

CVD (Chemical Vapor Deposition) furnaces are special furnaces used in the CVD process, which is a technique for producing coatings through chemical reactions in the gas phase, e.g. from MTS (CH3SiCl3-Methyltrichlorosilane ...

SECO/WARWICK S.A.

Maximum temperature: 2,300 °C

Capacity: 75 l

Width: 40 cm

The Cristal range is made of furnaces dedicated to heat treating under vacuum at high temperatures. The enclosure is insulated with specific metals, with a possible choice of molybdenum or tungsten resistors. It is the ...

ECM Technologies

... door. These furnaces replace batch atmospheric installations, sealed quench and IQ furnaces, for carburizing, carbonitriding, brazing & hardening applications. PLUS AND BENEFITS Vacuum Oil Quenching Furnace ...

ECM Technologies

Width: 8,000 mm

The ICBP® Nano is the latest product from ECM Technologies in the range for Low Pressure Carburizing and Carbonitriding. ICBP® Nano can be easily integrated into production lines and will allow you to cut down the time of the cycle ...

ECM Technologies

Maximum temperature: 3,000, 2,400 °C

Capacity: 9.5, 2.5 l

Width: 1,300, 1,400, 1,500 mm

... with the VHT models (page 62 ff), the retort furnaces of the SVHT product line offer improved performance data with regard to achievable vacuum and maximum temperature. Due to the design as pit-type furnace ...

Nabertherm

Maximum temperature: 2,200 °C

Capacity: 8 l - 600 l

Width: 1,300, 2,500, 2,300, 2,100, 1,900 mm

The Graphite Furnace HTK GR operates with rough/fine vacuum, protective gases such as Nitrogen/Argon, and reactive gases like Hydrogen and Carbon Monoxide. The Graphite Furnace ...

Maximum temperature: 2,200 °C

Capacity: 50, 80, 200 l

Width: 2,400 mm

HTBL bottom loading graphite furnaces offer temperatures of 2200 °C or 3000 °C upon request. Graphite models of the HTBL are offered in volumes of 50, 80 and 200 litres. One clear ...

Maximum temperature: 2,200, 3,000 °C

Capacity: 1.5, 10 l

Width: 1,900 mm

... the LHT high temperature laboratory furnace series is a compact design, making it the perfect tool for laboratories in research and development environments. The cylindrical usable space of the laboratory furnace ...

Maximum temperature: 2,800, 1,800 °C

Capacity: 4 l - 45 l

Width: 140 mm - 360 mm

... designed and produced atmosphere controlled lift bottom furnace to make heat treatment under the protective atmospheric conditions such as argon, nitrogen, vacuum, hydrogen and the like. MSE Furnace ...

MSE TEKNOLOJİ LTD. ŞTİ.

Maximum temperature: 2,800, 1,700, 1,600, 1,100 °C

Capacity: 12, 8, 5, 4 l

... atmosphere controlled chamber furnace for heat treatment under the atmospheric conditions such as argon, nitrogen, vacuum, hydrogen and the like. The cabin of furnace is water-cooled. And cabin of the ...

MSE TEKNOLOJİ LTD. ŞTİ.

Maximum temperature: 1,800 °C

Capacity: 43 l

Width: 350 mm

... are integrated into the furnace as standard. Lift bottom enables heavy and large samples to be placed more easily on the bottom of the furnace. The heating cabin of the furnace consists of graphite ...

MSE TEKNOLOJİ LTD. ŞTİ.

Maximum temperature: 1,600, 1,100, 1,800, 1,700 °C

Capacity: 3.9 l - 15.8 l

Width: 89, 93 cm

ACF series furnaces are specially designed for research and processes for larger volume products under controlled atmospheric conditions. Standard ACF series furnaces cover a range from 1100°C to 1800°C, ...

Maximum temperature: 0 °C - 3,000 °C

Industrial vacuum furnace with a maximum temperature of 3000 °C (5432°F) with our tungsten hot zones and 2200 °C (3992°F) with our graphite hot zones with operation in vacuum. Available with different ...

Materials Research Furnaces

Maximum temperature: 1,650, 2,200, 2,300, 2,600 °C

Our 15 Ton (133 KN) Hot Pressing Furnace is available with larger chamber and hot zone sizes and is housed in a larger frame. The frame is able to handle the higher forces and larger samples compared to our 5 and 10 ton ...

Materials Research Furnaces

Maximum temperature: 2,600, 2,300, 2,200, 1,650 °C

... force is reached. Temperature control is established by use of a thermocouple and/or pyrometer. The furnace can easily be converted to a batch furnace for production.

Materials Research Furnaces

Maximum temperature: 1,400 °C - 1,820 °C

Capacity: 4 l - 52.5 l

... Resistance heated by MoSi2, molybdenum, tungsten or graphite heater Chamber furnace Gas tight Maximum operating temperature up to 2100 °C Insulation by a combination of high quality ceramic fiber, ...

Linn High Therm

... market and the thermal field of the furnace is up to 40 inches. Strong compatibility 1600 monocrystal growth furnace is compatible with different size of thermal fields (up to 40 inches) Flexible ...

Maximum temperature: 1,250, 1,350, 1,500 °C

The BMI vacuum furnaces of the B5_T family are designed for the main high-temperature heat treatments that do not require high cooling rates (high pressure of up to a maximum of 2 bars abs can be applied to the equipment). ...

B.M.I. Fours Industriels

... both metallic shielded or graphite insulated hot zones, depending on your specific processing requirements. Graphite Hot Zone Construction: AMS 2750 compliant Insulation: multiple layers of 0.5” ...

Solar Manufacturing

... of industrial kiln burning, such as the process of soft magnetic ferrite drainage, the process of Zinc Oxide valve cutting, the firing process of graphite negative electrode, the sintering process of ...

Maximum temperature: 1,200, 1,400 °C

An induction furnace adapted for melting bullion bars of a precisely defined mass. The precisely weighed material is poured into dies of the desired shape and melted by the electromagnetic field in the shortest possible ...

Maximum temperature: 1,600 °C - 1,700 °C

... Aluminous linings or casings cooled with water without lining. Below tuyeres \ Refractory products with silicon carbide and graphite.

INSERTEC INDUSTRIAL FURNACES INSERTEC, S.L.U.

HORIZONTAL CONTINUOUS CASTING MACHINES FOR PRECIOUS METALS CHARACTERISTICS OF THE SYSTEM Machined graphite crucible. Compact construction in minimum space. Adjustable cooling water. Digital counter for casting ...

HORMESA CONTICAST HORNOS Y METALES S.A.

... application, the systems which can be operated with DC or AC power are equipped either with water-cooled metal torches or special graphite electrodes. The plasma arcs are stabilised with argon. Where several torches are ...

Sintering furnaces Pressing in molds of iron metal powders performs the construction of complex mechanical elements: this is the Sinterizing heat treatment. Such powders are previously mixed with other components such ...

Maximum temperature: 0 °C - 1,050 °C

... Production In Principle the ESY–10 Graphite System consists of alternating fixed and movable graphite Plates with Hollows holding the Substrates. The System Capacity is determined by the Stack Height ...

... features of furnaces in terms of temperature uniformity and production velocity. The answer to these requirements is realized by this series of furnaces thanks to the use of sophisticated temperature ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining