- Machine-tools >

- Finishing Machine >

- Grinding machine

Grinding machines

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

... spherical processing: pre- and fine grinding, edge grinding, chamfering and diameter reduction Grinding in standard and swivel mode Integrated center thickness ...

Satisloh

... precision optics grinding machine covers a wide workpiece range from 5–200 Ø in mm. The unique dual-spindle technology and axis design enables superior speed and consistent processing of spheres, aspheres, ...

Satisloh

Spindle speed: 2,500 rpm - 40,000 rpm

Power: 3 kVA

Choose the SPM-50 CNC grinding machine for the production of small to midsized optics, from Ø 5 mm up to Ø 50 mm. Best fit for combining the production of small AND midsized optics SPM-50 features ...

Satisloh

Spindle speed: 1,640 rpm

Power: 3 kW

Distance between centers: 400, 650 mm

... connected to the machine. Can be expanded to include in-process gauging and Sensitron Automatic grinding cycles for plunge and traverse grinding Automatic grinding ...

STUDER

Spindle speed: 2,110 rpm

Power: 6 kW

Distance between centers: 650, 1,000 mm

... enclosure permanently connected to the machine. Can be expanded for measuring systems and Sensitron Granitan® S103 mineral casting machine base Automatic grinding cycles ...

STUDER

Spindle speed: 3,200 rpm

Power: 8 kW

Distance between centers: 400, 1,600, 1,000, 650 mm

... cylindrical grinding machine for the individual and batch production of short to long-sized workpieces. It has a distance between centres of 400mm (15.7") / 650mm (25.6") / 1,000mm (40") / 1,600mm (63") ...

STUDER

Spindle speed: 60,000 rpm

Power: 7.5 kW

Distance between centers: 1,000 mm

... the customer. The KELLENBERGER 10 universal CNC OD/ID grinding machine is a new, high-performance, and economical grinder for use across a wide array of medium- to large-scale universal grinding ...

Hardinge Bridgeport

Machine weight: 10,500, 9,700, 9,000, 14,000 kg

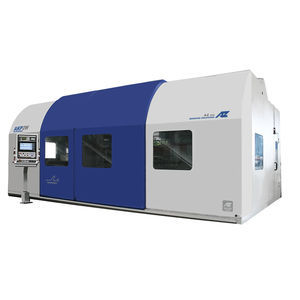

... continuous one-piece machine base Machine completely enclosed by durable cabinet Electrical cabinet built onto machine base extension Robust belt drive for common abrasive ...

IMM Maschinenbau GmbH

Machine weight: 4,500 kg

... continuous one-piece machine base Machine completely enclosed by durable cabinet Electrical cabinet built onto machine base extension Robust belt drive for common abrasive ...

IMM Maschinenbau GmbH

Machine for belt grinding, polishing and finishing of extrusion screws, large crank shafts and rotors. 11 interpolating CNC axes guarantee a perfect positioning of the endless abrasive ...

IMM Maschinenbau GmbH

BG-32 BELT SURFACE GRINDING SPECIMEN MACHINE 1. Application: Model BG-32 Belt surface grinding machine is of new generation design, made according to the international ...

Jinan Hensgrand Instrument Co.,Ltd

... efficient way. The machine can replace those grinding wheel machine and pre-grinder. It adopts manual abrasive paper grinding and each belt can finish ...

Jinan Hensgrand Instrument Co.,Ltd

BG-30 BELT SURFACE GRINDING SPECIMEN MACHINE 1. Application: Model BG-30 Belt surface grinding machine is of new generation design, made according to the international ...

Jinan Hensgrand Instrument Co.,Ltd

Spindle speed: 5,500, 4,500 rpm

Power: 0.45, 0.15 kW

... grinders are ideal for grinding HSS- and HM-spiral drills. Due to the adjustable point angles from 90° to 140°, this model can be universally used. Easy handling and their efficiency make these machines ...

... enables 3-fold utilization of the diamond disk - Short grinding time - only 0.3 mm consumption per grinding process due to grinding gauge - Speed control for optimum grinding ...

Distance between centers: 1 mm - 50 mm

Grinding wheel diameter : 305, 405, 455, 510 mm

Machine weight: 1,500, 2,400, 3,200, 3,700, 4,000 kg

The RC series centerless grinding machines can be used for infeed grinding and thrufeed grinding to ensure accuracy, high productivity in workpieces with diameters between ...

PARAGON MACHINERY CO., LTD.

Distance between centers: 1 mm - 50 mm

Grinding wheel diameter : 305, 455 mm

Machine weight: 1,700, 3,300 kg

The RC series centerless grinding machines can be used for infeed grinding and thrufeed grinding to ensure accuracy, high productivity in workpieces with diameters between ...

PARAGON MACHINERY CO., LTD.

Distance between centers: 1 mm - 50 mm

Grinding wheel diameter : 455, 510 mm

Machine weight: 3,500, 3,900 kg

The RC series centerless grinding machines can be used for infeed grinding and thrufeed grinding to ensure accuracy, high productivity in workpieces with diameters between ...

PARAGON MACHINERY CO., LTD.

... to grind multiple flat surfaces on a single piece, maintaining a high quality standard. • CNCS grinding unit flexibility. • Quick and certified machine set-up, thus immediate production change.

Spindle speed: 2,850 rpm

Power: 0.7 kW

X travel: 300 mm

This machine is equipped with a high-performance PC incl. touchscreen and digital jogwheel. This PC controls three linear- and a rotary axis simultaneously. The geometry of grinding is flexibly programmable ...

Spindle speed: 5,000 rpm

Power: 250 W

... reducing the diameter of end mills by grinding or grinding in of grooves as well as plain grinding of front faces. 3 jaw chuck Ø 3-30 mm push through: Ø 16 mm Spindle ...

Spindle speed: 1 rpm - 1,000 rpm

Distance between centers: 250 mm

X travel: 200 mm

... realize more complex contours for both internal and external grinding operations, this CNC machine allows linear and circular synchronization between longitudinal and transversal axes. A man-machine ...

LIPEMEC

Spindle speed: 4,000 rpm

Power: 0.37 kW

Distance between centers: 243 mm

This surface grinder is our smallest series. Especially adapted for precision machining, its reliability and ease of use make this production tooling essential for a daily use. CHARACTERISTICS - Vertical travel: - 180 mm Table: - ...

LIPEMEC

Spindle speed: 2,900 rpm

Power: 1.1 kW

Distance between centers: 315 mm

This machine, with three versions, is ideal for small batch machining with high quality requirements. Main pieces made from quality stabilized cast iron and rigid grinding wheel spindle ...

LIPEMEC

Grinding wheel diameter : 90 mm

... tool cassettes possible - Integrated loading system FLUTE GRINDING DIA. 1 – 12.7 MM HSS tap: M1, spiral fluted Cycle time: < 50 s Grinding task: Grinding the three ...

Erwin Junker Maschinenfabrik GmbH

Grinding wheel diameter : 350, 500, 700 mm

... balancing on two levels Grinding machines for grinding camshafts, cam pieces and individual cams combine non-cylindrical grinding for the cams and cylindrical grinding ...

Erwin Junker Maschinenfabrik GmbH

Power: 11 kW

Grinding wheel diameter : 120 mm - 200 mm

... descriptions FLUTE GRINDING DIA. 2 – 20 MM HSS tap: M12, straight fluted Cycle time: < 75 s Grinding task: Grinding the three chip and peel flutes Equipment and Options MACHINE ...

Erwin Junker Maschinenfabrik GmbH

... orbital grinding systems, to grant high volume production of polished tubes, bars and steel wire. This medley enabled us to develop a technological innovation where special pressure rollers in combination with high power ...

Power: 3 kW

... by Garboli, is suitable for use in grinding, buffing, and satin finishing of straight parts. This straight component is designed from stainless steel, iron, aluminium, and brass materials. This belt grinding ...

X travel: 150 mm

Y travel: 120 mm

CNC GRINDING MACHINE FOR TURBINE BLADES model "SPT/cnc" The grinding machine is engineered by Sibo, and is specifically designed for grinding the top ...

Spindle speed: 8,500 rpm

Power: 11, 23 kW

X travel: 350 mm

... strengths of an innovative grinding machine with a powerful erosion machine – and makes it possible to switch between both functions in next to no time. The VHybrid delivers noticeably ...

VOLLMER will present the machine concept for its innovative VLaser 370 for the first time in spring 2020, originally known as VLaser 270. This will open a new chapter for VOLLMER in the machining ...

Spindle speed: 420, 160, 300 rpm

Power: 24, 36, 12 kW

Double sided fine grinding machines, use fixed abrasive in lieu of loose abrasive for precision finishing. Depending upon the application, fine grinding ...

Specifications: - Lapidary for grinding cylinders or core samples (optionnal kit) - Diamond grinding system - Continuous watering system on the grinding wheel - Closed water circuit ...

Lapidary for grinding cylinders and cubes (optionnal) Diamand grinding system Waterproof continment case entirely made of stainless steel Rigid grinding door with a protection hood Continuous ...

Power: 5.5 kW

Specifications: Lapidary for grinding concrete cylinders samples 2 diamond grinding wheels for grinding SIMULTANEOUSLY the 2 sample faces Continuous water system on the diamonds of ...

... can integrates OD and ID operations in one machine, this reduces machining overhaul times. Different machine configuration are possible depending on the application and customer requirements. The ...

AZ spa

Spindle speed: 500 rpm

Power: 15 kW

Distance between centers: 3,100 mm

AZ Universal grinding machines range has been designed to fulfil the requirements of a wide range of applications that combine external, internal, face and taper grinding of components ...

AZ spa

Grinding wheel diameter : 760 mm

... lenght of external grinding 1550 [mm] Max diameter of grinding wheel 760 [mm] Width of grinding wheel 100 [mm] FEATURES headstock can swivel manually fixed grinding ...

AZ spa

Spindle speed: 0 rpm - 600 rpm

Power: 20 kW

X travel: 400 mm

GP-Rundschleiftechnik GmbH

Spindle speed: 0 rpm - 1,000 rpm

Power: 7.5 kW - 30 kW

X travel: 180 mm - 360 mm

GP-Rundschleiftechnik GmbH

Spindle speed: 0 rpm - 1,000 rpm

Power: 7.5 kW - 30 kW

X travel: 180 mm - 360 mm

GP-Rundschleiftechnik GmbH

... centerless grinding machine, static pressure structure centerless grinding machine, dynamic and static combined centerless grinding machine, ...

Ningbo CCMS Industrial Co., Ltd.

Spindle speed: 1 rpm - 1,350 rpm

Power: 15, 3 kW

Grinding wheel diameter : 455, 255 mm

... centerless grinding machine, static pressure structure centerless grinding machine, dynamic and static combined centerless grinding machine, ...

Ningbo CCMS Industrial Co., Ltd.

Spindle speed: 1 rpm - 1,460 rpm

Power: 15, 3 kW

Grinding wheel diameter : 255 mm

... centerless grinding machine, static pressure structure centerless grinding machine, dynamic and static combined centerless grinding machine, ...

Ningbo CCMS Industrial Co., Ltd.

Spindle speed: 4,400 rpm

Power: 120 W

... THE CUTTING EDGES, THINNING OF THE CORE FOR GREATER PRECISION. POSSIBILITY OF SHARPENING CARBIDE TWIST DRILLS WITH OPTIONAL GRINDING WHEEL.

Spindle speed: 4,400 rpm

Power: 200 W

WITH ER COLLETS, SUITABLE FOR SHARPENING MILLS WITH 2, 3 AND 4 CUTTING EDGES. POSSIBILITY TO SHARPEN HARD METAL MILLIS WITH OPTIONAL GRINDING WHEEL.

Spindle speed: min 1450.0 rpm

Power: 2,200 W

New vibration grinding and finishing machine TB-200B The vibrating grinding and finishing machine uses a vibrating motor as the excitation source to make the working ...

Tongbao Surface Processing Equipment

Vibration Grinding and Finishing Machine with Muffler Cover TB-200BC The vibrating grinding and finishing machine uses a vibrating motor as an excitation source to ...

Tongbao Surface Processing Equipment

Spindle speed: 33 rpm - 50 rpm

Power: 0.8 kW - 7 kW

Roll barrel grinding and polishing machine(Roller batch processing polishing machine) The barrel grinding and polishing machine adopts a horizontal ...

Tongbao Surface Processing Equipment

Transportable valve grinding machine - flat seats The transportable grinding machine is specially designed for machining flat sealing surfaces in valves, ...

APOLLO 13 is an ENDMILL GRINDING MACHINE which is possible to grind φ4.0~φ13.0. They have been sold in many foreign countries and both 100V and 220V - 230V is capable. Specification *Applicable ...

Spindle speed: 3,600 rpm

Power: 559.2 W

Machine weight: 280, 320 kg

Longitudinal travel of table - 230mm Cross travel of saddle - 180mm Vertical Adjustment of Wheel Head - 120mm Rotary angle of wheel head - 360° Rotary angle of up-down spindle - 360° Working Table Area - 620 x 190mm Size of Wheel - 180 ...

Spindle speed: 18,000 rpm

... for BT30/ BT40.50 2. On-site grinding - No teardown, Less downtime. 3. Extend the servcie life of the spindle 4. Improve machingin accuracy & extend the life of cutting tool 5. The precision after grinding: ...

Spindle speed: 4,000 rpm

Power: 7.5 W

GRINDING MACHINE FOR FLAT PLATES BACK GAUGING GRINDING DISC DIA. 300 MM Compact grinder, very light and manoeuvrable machine, designed for back ...

GBC UK

Your suggestions for improvement:

the best suppliers

Subscribe to our newsletter

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining