- Production Machines >

- Other Manufacturing Equipment >

- Hammer mill

Hammer mills

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

... sodium bicarbonate, pigments, metal and polymeric powders, calcium carbonate, graphite, lithium, etc.) are grinded by hammer mills, pin mills, JetMill (with opposing air jets) and separated ...

Final grain size: 6, 8 mm

Motor power: 75, 132 kW

Machine weight: 4,500, 8,200 kg

The ZHM series of hammer mills feature heavy duty rotors ranging from 600 to 800 mm diameter and widths between 800 and 1200 mm directly driven via Vs.-belts. The fixed rotor tools, heavy counter knives ...

Rotational speed: 7,500, 5,550, 12,000 rpm

Output: 5 kg/h - 500 kg/h

Motor power: 3 kW - 15 kW

Tooth claws, movable hammers, hammers, and grinding discs are easy to replace. It is widely used in chemical industry, inorganic salt, medicine, food, pigment, dye, pesticide, battery material, mineral, ...

Rotational speed: 450 rpm

Motor power: 4 kW

The MACSA 300 Overhung Disintegrator Hammer Mill has been designed to satisfy the needs of Laboratories, Research Institutions and Industries requiring size reduction on a semi-production scale. The ...

MACSALAB Hi - Cap Impact Hammermill The range of Macsa Impact Hammer Mills is specifically designed for reduction of medium hard to hard friable materials. The dynamically balanced rotor ...

Rotational speed: 600 rpm - 6,000 rpm

Output: 1,500 kg/h

... the L.B. Bohle Hammer Mill Hammer or turbo mills are suitable for research and development, as well as for batch production or continuous manufacturing. They are ...

NEUE HERBOLD HM series hammer mills offer flexibility in their application range. Through the installation of material oriented rotor milling hammers tools various types ...

The MTS Crusher Mill of PIMECSA, is a hammer mill that rotates at high speed within a chamber with sieve and fulfill the functions of crusher / lump breaker and sieve. ...

... product. The final size of the grain is determined by the setting of the screen hole diameter and the mill speed. The product only leaves the hammer mill when it is smaller than the screen ...

Output: 1 t/h - 100 t/h

Motor power: 3 kW - 160 kW

Machine weight: 750 kg - 7,000 kg

The WJR – WJRU – WF mills, derived from WEIDKNECHT machines, have proved their worth in grinding clays, limestone, chalk, lime, plaster, coal, chemical products and fertilisers, mushroom soil, and in grinding bark, peat, ...

Output: 1 t/h - 75 t/h

Motor power: 4 kW - 250 kW

Machine weight: 450 kg - 16,300 kg

The BME mill’s yoke hammer system has proved its worth in grinding semi-hard and hard materials Hundreds of “BMEs” are used in the refractory product, lime, plaster and agglomerate industries, ...

... to form lumps when extracted from silos or storage hoppers. UNCTIONING The product is crushed by one or more rotating hammer or blade tools. A screening grid below only allows material of the specified particle size ...

Rotational speed: 50 rpm - 6,000 rpm

Hammer grinding / Laboratory mill, dry sample preparation with CH-power cable, hammer grinding attachment, sieve 2.0 mm, tool set, rack for tubes with 12 intercepting tubes (230 V) Analysis ...

Rotational speed: 3,000 rpm - 14,000 rpm

High-speed hammer mills designed for continuous operation in harsh environments at peripheral speeds of up to 100m/s. Applications Production of carbon black Cosmetics and pharmaceutical products ...

Output: 40, 100, 342, 500 t/h

... control and separation. The FAM product range includes impact mills, roller mills, hammer mills, ball mills and rod mills, as well ...

FAM

Output: 1 t/h - 8 t/h

We can supply hammer mills for size reduction tasks that mainly need to be done by means of impact and blows. We build them in sizes from 450 x 600 to 1000 x 2500 mm circle of rotation diameter x working ...

Rotational speed: 1,500, 1,200, 1,800 rpm

Motor power: 55 kW - 450 kW

... all wear elements such as hammers, screen and impact sheets. Hammer mill Granulex® 5 Series The smart modular design increases the flexibility to meet the requirements of any application. ...

Bühler Group

Output: 10 t/h - 70 t/h

The Impact Hammer Mill, series PHPH ''Grizzly®'' was developed for the economical size reduction of residual- and waste wood of any kind. Not only pre-broken waste wood but also non precut, long recycling ...

Pallmann Maschinenfabrik

micronizer air jet mill, with cyclone separator, dust collector and draft fan to constitute a grinding system. Compressed air after being dried is injected into grinding chamber quickly by the injection of valves. At ...

Motor power: 45, 132 kW

Machine weight: 9,000 kg - 13,000 kg

Hammer mills are particularly suitable for metal scrap, electrical and electronic scrap or swarf made of steel, aluminium, but also other materials. And due to the easy adjustability during operation, ...

ERDWICH Zerkleinerungs-Systeme GmbH

... major damage to the rotor and hammers. Sucrose extraction maximized The shredding action of such equipment exposes more fiber particles and ruptures more sucrose bearing cells than knifing alone. This allows the ...

... electric motor / Motor Assistant / Transmission ATF. Of a> 4 Position Control System. The impact plate and interchangeable hammers

Rotational speed: 3,000 rpm

Output: 2,500 kg/h

Motor power: 37, 45, 55 kW

... low options for realization wood chips are usually discarded by selling it to heating plants for a low price. Our MM-2000 hammer mill allows companies to turn wood chips into briquettable sawdust by shredding ...

The new 3100 Laboratory Mill combines efficient milling with a pleasant dust-free and noiseless atmosphere. The 3100 is a hammer mill which crushes the product at ...

It is suitable to crush tomato or fruit which need to be crushed after the sorting process. The product is impacted by the hammer bars, rotating at high speed and thereby crushed and then expelled through a sieve fixed ...

Output: 20 t/h

The Komplet M5000 hammer mill is an electric-powered static crushing machine, it is reliable and provides high-capacity and performance. It features a loading conveyor to feed the hammer ...

Rotational speed: 1,000 rpm

A fleeting glimpse on the 6 m wide feed hopper is enough to find out that the AK 635 SA EcoPower is destined for greater things. But not just in this respect the largest machine of the series stands out – there are numerous other features ...

Your suggestions for improvement:

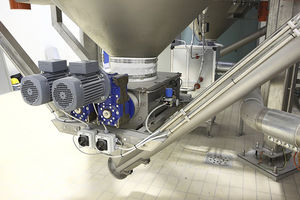

The hammer mill has a strong, thick-walled drum. As product is fed into the machine, hammers mounted on a rotor spin within at high speed, grinding and crushing it against a sieve to produce particles of a desired size.

ApplicationsThe hammer mill is used primarily in industrial settings. It can provide a reduction ratio of as much as 20:1.

TechnologiesDepending on the material to be treated and the desired particle size, the mill's hammers will be of different weights and spin at different speeds.

How to chooseChoice will depend on the type and size of the material to be ground, as well as the desired final particle size.

- Very durable

- Large capacity

- Damaged by very hard or abrasive materials

the best suppliers

Subscribe to our newsletter

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining