- Packing - Handling - Logistics >

- Conveying >

- Handling pneumatic conveying system

Handling pneumatic conveying systems

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

... turnkey pneumatic conveying systems: knowledge of the entire range of conveying techniques, knowledge of processes and products based on millions of hours of system ...

... SeriesTM vacuum receivers for conveying applications in the food, pharmaceutical, chemical, nonwovens and plastics industries - ideal for free-flowing and non-free flowing powders and granular bulk materials. ...

VAC-U-MAX

... , No lifting, No dust •Automatic Feeder Refill •No Compressed Air Required •Vacuum Receiver Sits on Feeder Cover •Packaged Set-in-Place, Hook-up, Operate!

VAC-U-MAX

... innovative mechanical and pneumatic design to produce ingredient handling systems that not only free operators of physical effort but also perform sophisticated pneumatic ...

VAC-U-MAX

... material loader is equipped with its own control, so that it recognizes when material is needed and automatically starts conveying. This keeps machines running and avoids costly downtime while eliminating material wastage, ...

... conveyor • easy product discharging, full bore opening • purely pneumatic powered systems with failsafe controls • electrical Vacuum Pumps upon request • valves, ...

... resistant and/or pressure-shock proof Vacuum Conveyor designs necessary. Pressure resistant Vacuum Conveyors from Volkmann can be operated like “standard” Vacuum Conveyors and run ...

... individually customised Vacuum Conveying systems and complete Vacuum Transfer solutions, that can be used for the conveying and dosing of Pharmaceutical ...

... products over distances up to 300 metres. Gentle handling of product The low velocity of this vacuum dense-phase pneumatic conveying machine ensures minimal product ...

... complete systems for bulk material handling, Coperion & Coperion K-Tron design and manufacture equipment for the pneumatic transport of bulk solids materials for small and large systems. ...

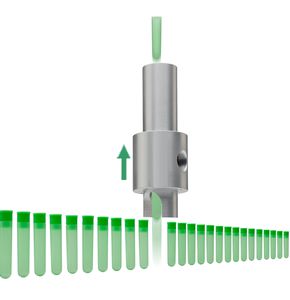

The PTS Powder Transfer System is built with optimized processes and multi-purpose operation. It ensures safe handling when it comes to transferring and dispensing either wet or dry powers and granules. ...

Dec Group

... valves on silos, CEPATIC system on loading, dispersing valves, magnets, pressure switches and sensors. Slide valves to stop the propagation of explosions and flames in the conveying system. ...

... different needs such as material packaging, handling, dosing, product mixing, distribution on different production lines, Mastervac offers compressed air or electrically powered pneumatic ...

... • Slow and gentle conveying with less compressed air and energy consumption • Simple, cost-effective system assembly • Less wear and tear due to low speed • No segregation ...

HOSOKAWA SOLIDS, S.L.

Pneumatic conveying systems from silo to injection molding machine or extruder – The navigation device for your material tracking and handling – QUALITY AND SAFETY The ...

... for pneumatic conveying - Ø of passage : from 4 to 100 mm Features: - In-line venturi with straight duct specialized for pneumatic conveying - Fully static, instant ...

... specifications: - Fluid: compressed air - Optimum pressure: 5.5 bar - Pressure range: 0 to 10 bar - Temperature range: - 50° to + 250°C Further information: Pneumatic conveying ...

Your suggestions for improvement:

the best suppliers

Subscribe to our newsletter

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining