- Industrial machines and equipment >

- Furnace and Heat Treatments >

- Hardening machine

Hardening machines

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

... is suitable for hardening in a protective gas atmosphere followed by quenching of the workpiece in oil. In this way, even larger parts can be annealed under a protective gas and quenched. It consists of a chamber furnace ...

... optimal homogeneity. Electricity: 3 x 400 VAC, 50 Hz. Regulation: Axron Swiss PID temperature controller. Documentation: CE marking and operating instructions in English. Delivered with: Furnace basket.

BIG BEARINGS HARDENING AND TEMPERING INSTALLATION Multi station Induction heat treatment (Hardening and Tempering) for Inner Ring and Outer Ring. The plant is divided into 2 similar and independent ...

Termomacchine S.r.l.

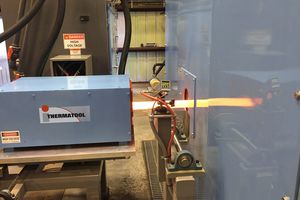

... UP TO 0 °C VERTICAL INDUCTION HARDENING MACHINE, 150 KW Applications: hardening Other possible applications are: Hardening of workpieces (shafts, rods, ...

... EFD Induction’s family of heat treatment systems for surface and through hardening, comprising a complete range of stationary systems for all types of workpieces requiring hardening, tempering and annealing. With ...

EFD Induction Group

The concept The INDUCTOSCAN MOVE is a universal vertical scanning machine with an indexing table module for hardening or tempering a wide variety of workpieces. The machine features ...

Inductoheat Europe GmbH

"For end termination of different electronic chip components previously inserted in to a carrier plate" • DM6 dipping machine with high dipping force makes possible to level the chips during the dipping process perfectly. • ...

... development and the manufacturing of an INDUCTION THROUGH HARDENING MACHINE for the hardening of steel rings. The main advantages of the equipment are: cost-effective induction ...

Just right after the press before the cooling unit there’s a short lead out table with high temperature resistant rollers and this table can move vertically to update to the different highs of the profiles. OMAV can supply different ...

... applications and is especially effective in hardening rolling mill rolls. Rail Hardening Systems have specially designed inductors which are used to heat the head of the rail and control the depth ...

... has revolutionised the heat treat market and surmounted long standing limitations to tubular and bar quenching. Effective hardening and tempering requires the ability to deliver uniformly heated material to achieve optimum ...

... tanks Quenching sprayers Bosio quenching tanks offer controlled cooling for hot loads to achieve surface or core hardening by dipping the load in to a homogeneous liquid, such as: Oil Water Water containing ...

Aichelin Group

... , max.685 mm Workpiece diameter, min.181 mm Workpiece height, max.203 mm Highly Versatile Process controlled quenching machine for gears, bearing races and other flat cylindrical parts up to 685 ...

Machine for the continuous hardening of mozzarella cheese and similar products of any size. Usually this is the last component/equipment of a string cheese (mozzarella, pizza cheese, etc.) production ...

Comat

... freezing in a hardening tunnel limits the growth of ice crystals, therefore conserves optimal ice cream texture. VOJTA Equipment HT tunnels are designed to rapidly freeze flat top cones, family packs, cups, and other ...

The machine is used to automatically immerse the overheated pieces in the oil bath to perform rapid cooling for hardening. This consists of a stainless steel structure to which the following parts ...

Heat treatment (Water Quenching) complete system with a capacity of 12000 kg, for forged pieces made of carbon steel and stainless steel. Diving platform sizes: 4000 x 4000 mm The used fluid is water, with a cooling evaporation ...

Your suggestions for improvement:

the best suppliers

Subscribe to our newsletter

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining