- Industrial machines and equipment >

- Furnace and Heat Treatments >

- Heat treatment oven

Heat treatment ovens

... electric furnace are welded by steel plate and section steel. Soft contact between the trolley and furnace lining can sharply reduce thermal radiation and connective thermal losses so as to guarantee ...

Anhui Xinning Equipment Company

... Increased quenching speed and uniform cooling. Flexible dynamic cooling system with alternating cooling gas flow, giving the furnace high flexibility. Can be adapted to a wide range of materials, geometries and loads. ...

Ipsen International GmbH

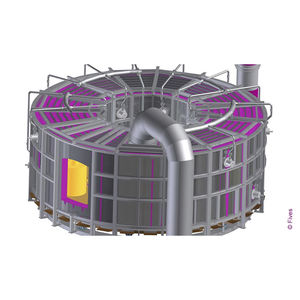

... grade steel ingots for railway wheels; and for heat treatment (annealing, quenching) of wire rod coils. State-of-the-art Stein rotary hearth furnace technology The Stein Helyo® RtH ...

Fives DMS

... curing oven requires as little as six feet of floorspace for cure cycles as long as four hours. Heller Vertical format ovens consume unused air space, not valuable floor space. The Heller 788 in-line, ...

Maximum temperature: 8 °C - 80 °C

The `safety first’ design includes an over-temperature protection system that automatically tracks the set temperature and controls the heater in the event of a fault. The smart system displays error codes indicating a fault has occurred ...

Maximum temperature: 500 °C

Capacity: 7,000 cm³

Furnace for the casting of low-melting metal alloys equipped with insulated lid for a higher energy efficiency. Moreover, it’s provided with a digital thermoregulator, which allows to set the temperature, and a timer ...

NICEM

This machine is designed to improve the cell efficiency by applying a passivation layer on the front side of the silicon wafer after Edge Isolation and PSG removal. Spec High Throughput: 14,400 wafers/hr (2,400 wafers/boat) Cycle ...

Maximum temperature: 100, 140 °C

Width: 1,500, 870 mm

Height: 1,150, 460 mm

The application area of Conveyor Ovens is versatile. Conveyor Ovens are suitable for continuous heating, thermal treatment or clock-controlled dwell times of components. Applicable are ...

Ihne & Tesch GmbH

In a Casthouse, Holding Furnaces are designed to supply casting machines with metal that is at the correct casting specification on a continuously repeatable basis. The furnace design integrates specific ...

Maximum temperature: 1,300 °C

... NEW H1 Nargesa propane forging furnace has been designed to heat irons more efficiently, more safely and respecting the environment. MORE EFFICIENT: Consume up to 75% less gas and reach a higher temperature ...

Maximum temperature: 100 °C - 800 °C

... recovery FLSmidth is a global leader in precious metals extraction equipment and systems. Our activated carbon regeneration kilns have been refined through innovative thinking for over 20 years. We simplify the carbon ...

... market and the thermal field of the furnace is up to 40 inches. Strong compatibility 1600 monocrystal growth furnace is compatible with different size of thermal fields (up to 40 inches) Flexible ...

Wuxi Autowell Technology Company

The FCB Kiln can be supplied with 2 or 3 supports, with a girth gear or a friction drive. The efficiency of the FCB Kiln is improved by the tyres design and the upstream & downstream seals. The FCB ...

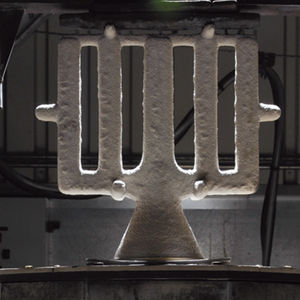

Roll-over melting furnace Ideal for high-precision melting and pouring, and for investment casting applications. High-frequency power sources ensure short melt times (and eliminates oxidation). Mould filling is extremely ...

EFD Induction Group

... is normally from 50 – 400 t/d. HORN also designs furnaces with 635 t/d. DESCRIPTION According to the glass quality, furnace capacity, raw material specifications and the type of glass, each furnace ...

HORN Glass Industries

Inductotherm's coreless induction furnaces offer superior performance and outstanding durability for all your melt shop needs regardless of the size of your molten metal needs. From small capacity, precision casting operations ...

Inductotherm

Maximum temperature: 0 °C - 1,050 °C

... line with new requirements, both in terms of capacity and treatments Particularly suitable for production of parts in medium and small production runs requiring flexibility of heat treatment ...

Codere

Maximum temperature: 2,400 °F

Width: 12 in

Height: 12 in

... Backed by fully stocked spare parts warehouse and the best technical support Full one year warranty The Mentor Vacuum Furnace Hot Zone Hearth: molybdenum support pins and rails Heating Elements: curved, segmented ...

Solar Manufacturing

... shaft furnace and the retort furnace are ideally suited for the heat treatment of slim small parts or for finishing by nitriding, carbonitriding or carburizing, for example. Shaft ...

HOFMANN WÄRMETECHNIK GMBH

Maximum temperature: 1,200 °C

Width: 450 mm

Height: 600 mm

1200℃ manual door industrial furnace is used for quenching, tempering, normalizing, annealing and other heat treatment processes of metal materials, and can also be used for sintering ...

Henan Sante Furnace Technology Co.,Ltd.

... Class A if required lowtemperature-7 Heat Treating Ovens Nutec Bickleys Heat Treating Ovens can be used for treating a variety of metals to harden, soften or cure ...

Nutec Bickley

... the Heat Treatment in real time, associating each detail to be treated with its recipe., In terms of "quantity" of heat and "administration time" of the same All this translates into ...

FARM NEW BRASS s.r.l.

Maximum temperature: 950 °C

Width: 550, 1,400, 1,350, 800 mm

Height: 450, 750, 950, 1,800, 1,700 mm

... special steel plate,shaft,rotary parts,centrifugal fan impeller Car bottom electric resistance type heat treatment furnace is one commonly used heat treatment ...

HENAN TIANLI THERMAL EQUIPMENT CO.,LTD

Maximum temperature: 400 °F - 2,200 °F

... unique and proprietary features of Epcon’s Industrial Heat Treatment Furnace designs include; Precision Programmable Temperature and Atmosphere Controls, Heavy Duty Car Bottom or Insulated ...

Epcon Industrial Systems, LP

... purpose, gas analyzers with infrared, paramagnetic cells etc… are required. Auxiliary equipment for heat treatment furnaces Heat treatment furnaces ...

SABE FORNI

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining