- Production Machines >

- Other Manufacturing Equipment >

- Horizontal mill

Horizontal mills

The KAHL crumbler is characterised by smooth operation and low wear. The advantages of the crumbles clearly lie in the optimum feed conversion by the animal. The crumbler is used in particular for the crushing of pellets and other softer ...

Using the KAHL crushing roller mill, legumes, oilseeds, and feed mixtures can be crushed efficiently and with a considerably lower expenditure of energy compared to the hammer mill. The rollers made of ...

Designed for secondary demolition, the KINSHOFER static pulverisers are available in three different sizes and two versions each: standard or Extreme version. Both can break up reinforced concrete structures and separate steel. All teeth ...

Final grain size: 10,000 µm

Rotational speed: 200 rpm

Output: 0 kg/h - 10,000 kg/h

... deagglomeration of compacted material into smaller particles. The Hanningfield Lump Breaker is designed for the simple deagglomeration of compacted material into smaller particles. Lump breakers can ...

Output: 5 t/h - 500 t/h

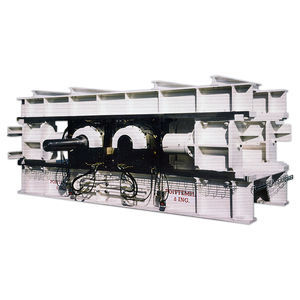

DESCRIPTION The Cylinder mill, commonly known as the Roller Press works by crushing the material between two cylinders kept under pressure by a hydraulic system (2 to 10 T/linear cm). This mill uses ...

POITTEMILL / FORPLEX

Output: 1 kg/h - 50,000 kg/h

... FNG is easy. The Universal mill is equipped with air insufflation at bearing level to eliminate all risk of cross-contamination in the case of multi-product use. The extensive FNG range starts with the FNG 00 laboratory ...

POITTEMILL / FORPLEX

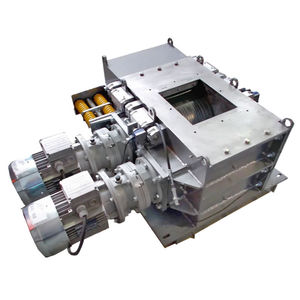

The BRF dual-rotor universal mill is an evolution of the FNG universal mill. The BRF’s design is based on FORPLEX impact crushers (such as the FNG or FPX models) but is engineered with two oppositely ...

POITTEMILL / FORPLEX

Motor power: 1.5 kW - 45 kW

Machine weight: 1,200 kg - 11,000 kg

Fluted smooth teeth : Mineral processing : Limestone Gypsum, Lime, Chalk, Cement, etc. Fuel processing : Coal, petroleum coke, etc. Coal, petroleum coke, etc. : Cullet, glass, concrete, bottom ash, etc. Chemical ...

... With less than 5% Less than 3.15 mm DIFFERENT TYPES OF MILLS FOR SPECIFIC APPLICATIONS Jaw crusher Roller Mill Ball mill Hammer mill ...

Motor power: 15 kW - 250 kW

Machine width: 300 mm - 2,000 mm

Machine weight: 1,500 kg - 20,000 kg

The TH, TFH and TSH hammer mills are suitable for shredding tough, fibrous materials that are slightly damp. Frame : Electro-welded structure in thick ribbed sheet metal. It is made up of two articulated housings ...

Output: 300 kg/h - 6,000 kg/h

•Average output 50micron with 90% <100micron. •Custom configuration with storage of different capacities. •Complies with ATEX. APPLICATIONS Grinding granular sugar into powdered sugar for use as an ingredient or as a finished product. ...

... The drum and balls can be sterilized in water. For using the ball mill, a drive support is needed, which is optionally available in a lengthened version for the simultaneous use of two mills of the same size.

... requirements. • Colloid Mill Chamber Versatility – The Bematek mill chamber can be easily rotated 360° to accommodate different piping arrangements in a process plant, further supporting multiple product ...

... to contact the stator. • Easy Mill Chamber Maintenance – This sanitary tri-clamp design allows quick and easy access to the mill chamber internal parts for inspection, cleaning, and mill ...

Motor power: 200 W

Machine length: 40 cm

Machine width: 26 cm

The MPC mill is ideal for fine trituration and homogenization of ointments, creams, pastes, gels and suspensions: it reduces particles to the optimal size for absorption into the body. The mill features ...

Rotational speed: 220, 330 rpm

Output: 200 kg/h - 600 kg/h

The machine is used separately or coupled with a crusher BLIK to ensure a perfect finition of material for a maximum valorization

Rotational speed: 220, 330 rpm

Output: 800 kg/h - 1,200 kg/h

The machine is used separately or coupled with a crusher BLIK to ensure a perfect finition of material for a maximum valorization

Demolition pulverizer Rotar Demolition Pulverizer Incredible crushing power combined with tremendous cutting power makes the Rotar Demolition Pulverizer the perfect pulverizer ...

Rotar

Output: 40 kg/h - 3,200 kg/h

Motor power: 4, 8, 15 kW

... Comex jet mill construction allows a precise nozzle position control which is of critical importance for efficient grinding. Capacity increases have been experienced when old jet mills have been replaced ...

Final grain size: 3 µm - 300 µm

Motor power: 370 W

Dry grinding systems, which include ball mills, are usually very complex and complicated. They require ball mills working in the closed circuit with an air classifier and a complete circuit has to operate ...

Final grain size: 200 µm

Rotational speed: 50 rpm - 3,000 rpm

Machine width: 270 mm

A compact benchtop grinding mill with powerful and shear crushing capabilities IQ MILL-2070 makes the sample grinding process into a simple pre-treatment operation. By using a special high elastic belt ...

The LiSEC float glass breakout system automatically breaks the trim cut at the front, the remnants at the trailing edge, as well as the X and Y sub-plates continuously, quickly and with consistently high breaking edge quality. Thanks ...

Output: 1,500, 3,000 kg/h

... for the needs of the food industry. • Fine impact mill with pin discs - integrated in a pressure-shock resistant stainless steel vessel • Easy-to-clean thanks to the wide opening of the mill ...

HOSOKAWA ALPINE

... level sensor for regrind bin. Link to the IMM's doors with On/Off function of the granulator's screw. Remote control box to operate the granulator from the opposite side of placement.

Rotational speed: 2,760 rpm

Output: 300 g/min

Machine length: 517 mm

... 4 • - Stepless adjustment of milling gap/degree of fineness • - Reproducible milling at the desired degree of fineness • - Minimal grist heating • - Reduced loss of moisture during milling • ...

... Versatile applications AG milling extends itself to many applications due to the range of mill sizes available. AG mills can accomplish the same size reduction work as two or three ...

Metso Corporation

Rotational speed: 420 rpm

Output: 400, 600, 750 kg/h

Motor power: 22 kW

The SPEEDGRINDER is a so-called "skeleton grinder" which grinds the residual skeleton which is produced in the thermoforming process after the packaging has been cut out. The crushed smallest parts can then be fed back into the extrusion ...

Motor power: 1, 2 kW

Machine weight: 120, 100, 200, 300, 500 kg

... energy-saving The unit is used for crushing and milling of bulk materials with a tendency to form agglomerates, clods and lumps. Bulk materials containing agglomerates, clods or lumps, are fed into the AZO lump breaker ...

Motor power: 6, 30 kW

The SML 16 models are a series of particularly wide machines with smaller rotor diameters for the processing of thin-walled panels and skeleton waste, directly in the deep drawing line. The very low design of the granulator makes it suitable ...

HERBOLD Meckesheim

In addition to sand mill, the grinding system also includes dispersion tank, homogenization pump, coarse grinding tank, fine grinding tank, diaphragm pump, heat exchanger, material conveying pipeline, ...

ONGOAL TECHNOLOGY CO., LTD.

The largest tub grinder on the market, the Morbark 1600 Tub Grinder is able to power through and reduce materials from large land clearing or organic/wood waste programs. With an 11’2″ tub diameter, 15′ tub opening and a capacity of 20 ...

Morbark, Inc.

Output: 23, 30 t/h

... control and separation. The FAM product range includes impact mills, roller mills, hammer mills, ball mills and rod mills, as well as appropriate roller screens.

FAM

The MCP-IT fixed Pulveriser is the ideal attachment for secondary demolition or rather for the work of reduction and fragmentation of the demolished material making disposal and recycling easier by separating the reinforced iron from ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining