- Production Machines >

- Other Manufacturing Equipment >

- Horizontal mill

Horizontal mills

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Rotational speed: 100 rpm - 1,100 rpm

FRITSCH Planetary Ball Mills – high-performance all-rounder in routine laboratory work The Planetary Micro Mill PULVERISETTE 7 premium line with 2 grinding stations is designed for a broad range of ...

Fritsch GmbH - Milling and Sizing

Rotational speed: 50 rpm - 400 rpm

Ideal for large quantities The Planetary Mill PULVERISETTE 5 classic line with 4 working stations delivers fast and reliable, due to the particularly high-energy effect of the grinding balls, loss-free grinding results ...

Fritsch GmbH - Milling and Sizing

Rotational speed: 400 rpm

Ideal for comminution with 2 working stations The Planetary Mill PULVERISETTE 5 classic line, with two working stations delivers fast and reliable, due to the particularly high-energy effect of the grinding balls, ...

Fritsch GmbH - Milling and Sizing

Machine weight: 9 kg - 40 kg

The Lump Breaking Feeder Valve enables safe and smooth segregation of bulk materials that tend to pack and form lumps during production and/or storage. Its design favours gentle crushing even with hardened material under a medium-high ...

Motor power: 2, 3, 4, 6 kW

Machine weight: 250, 340 kg

The DLP Lump Breaker is an efficient, economic machine specially designed for breaking up friable lumps in bulk materials discharged from silos, bins or hoppers. The DLP Lump Breaker consists of a ...

The PM 300 is a planetary ball mill with 2 grinding station. The maximum batch size is 2 x 220 ml. Planetary ball mills comminute by impact and friction and achieve grind sizes down to 1 micron, in colloidal ...

Retsch GmbH

Rotational speed: 10 rpm - 50 rpm

PRODUCT ADVANTAGES PULVERIZATION OF LARGE SAMPLE VOLUMES The Drum Mill TM 500 is a laboratory ball mill designed to grind large sample volumes up to 35 l. It accepts initial feed sizes of up to 20 mm ...

Retsch GmbH

Rotational speed: 10,000, 12,000, 14,000 rpm

The cyclone mill TWISTER is designed for sample homogenization of food- and feedstuff for subsequent NIR analysis. The form of rotor and grinding chamber has been optimized to generate an air jet which transports the ...

Retsch GmbH

Rotational speed: 2,760 rpm

Output: 300 g/min

Machine length: 517 mm

... 4 • - Stepless adjustment of milling gap/degree of fineness • - Reproducible milling at the desired degree of fineness • - Minimal grist heating • - Reduced loss of moisture during milling • ...

Rotational speed: 1,410 rpm

Output: 100 g/min

Machine length: 515 mm

Quadrumat Junior: New roller mill for user-friendly lab flour preparation What is it used for? The Brabender Quadrumat Junior is a universal laboratory roller mill with integrated separation and aspiration ...

Machine weight: 300 kg

The Brabender Quadrumat Senior is a universal laboratory test mill with versatile applications: Production of test flours identical to those used in practice, determination of the milling properties ...

Rotational speed: 25,000 rpm

... redesigned batch mill grinds hard, brittle, soft and fibrous materials for volumes up to 50 ml. Because samples may be embrittled directly in the grinding chamber; tough, oily and aqueous samples can also be grinded. The ...

Rotational speed: 20,000 rpm

Machine width: 170 mm

Machine height: 350 mm

Batch mill suitable for dry grinding of hard and brittle substances up to 250 ml with a fixed speed of 20.000 rpm. • Double-walled grinding chamber can be cooled with water through two hose adapters • Removable grinding ...

Final grain size: 5 mm

Rotational speed: 150 rpm

Output: 50 kg/h - 200 kg/h

• Direct driven staggered rotor • Special knife design makes adjustment unnecessary • Easy access for maintenance and cleaning • Slow rotor speed creates less noise and dust • Easily customizable to suit different applications The ...

Final grain size: 6, 8 mm

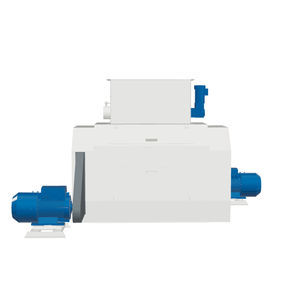

Motor power: 75, 132 kW

Machine weight: 4,500, 8,200 kg

The ZHM series of hammer mills feature heavy duty rotors ranging from 600 to 800 mm diameter and widths between 800 and 1200 mm directly driven via Vs.-belts. The fixed rotor tools, heavy counter knives and several rows ...

Output: 30 t/h - 7,400 t/h

Motor power: 45 kW - 7,000 kW

In recent years, with the continuous consumption of high-grade ores, the characteristics of poor, fine and miscellaneous minerals have become prominent, and the sorting and processing of low-grade and refractory ores has become the main ...

Rotational speed: 428, 360, 348, 270 rpm

Motor power: 1 kW

Machine length: 762, 660, 610, 1,676, 927 mm

... adequately dispersed in conventional high shear mixers. Benefits of Choosing a ROSS Three Roll Mill What does a ROSS Three Roll Mill do? A Three Roll Mill is composed of three ...

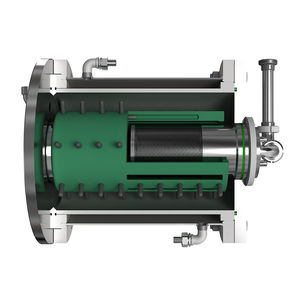

... demanding customer requirements. We are the only company to offer basket, pin, circulation and passage mills. We have been building horizontal disc mills for more than 40 years, and ...

NETZSCH Grinding & Dispersing

... diameter. The closed horizontal agitator bead mill is designed for the highest product throughput rates and has a peg grinding system with extremely high grinding intensity. Easy and ...

NETZSCH Grinding & Dispersing

The high-speed mill system Zeta® with improved peg grinding system optimizes your production capacity, energy demand and quality. Designed for circulation operation and multi-pass operation, you achieve ...

NETZSCH Grinding & Dispersing

Output: 6 t/h

Motor power: 60 kW

Tailored flakes: The SCHULE flaking roller mill rolls each flake to the desired thickness. Flaking Oats, Rice, Spelt, Buckwheat, Wheat, Rye, Barley, Quinoa, Peas, Lentils The product is fed to the two flaking rolls ...

... services in grain milling operations. Rugged high-capacity grinding system with high throughput capacity. •The innovative design allows throughput capacities as high as 1000 metric tons per day to ...

Bühler Group

Flaking Mill DOQB As a manufacturer of food processing machinery, Bühler is also a leading supplier of oilseed processing equipment used in oilseed preparation and handling. The Bühler flaking mill ...

Bühler Group

Flaking Mill DOZC As a manufacturer of food processing machinery, Bühler is also a leading supplier of oilseed processing equipment used in oilseed preparation and handling. Bühler's proven flaking mill ...

Bühler Group

Motor power: 75, 40, 15 ch

Machine weight: 450, 1,000, 2,100 lb

... . The Admix MayoMill is an inline milling device designed to eliminate the common issues with conventional, colloid mills popular throughout the industry. Features/Benefits - MayoMill vs. colloid mills Wet ...

Final grain size: 2 µm - 16 µm

Output: 400 kg/h - 10,000 kg/h

... rate. High energy utilization rate, low operating cost, grinding particle size range D50: 0.5-10μm. The revolution of dry milling technology, the milled particle size can reach sub-micron or nanometer level, which greatly ...

... designed, manufactured, and installed more than 8,000 ball/pebble mills, all over the world. Both the ball and pebble mills utilize a tumbling media, ball mills with steel balls, and ...

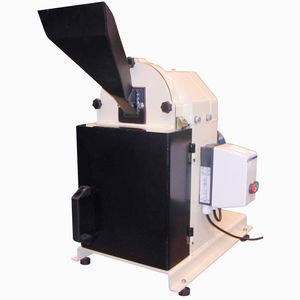

Rotational speed: 6,000 rpm

Motor power: 2 kW

Machine weight: 68 kg

... The 200 Lab Mill is used for crushing: Bricks Chemicals Coal Concrete Grain Ores & Minerals Soil Spices and many more materials in the medium hard range. Once the material is fed into the feed chute, it quickly ...

... of Macsa Impact Hammer Mills is specifically designed for reduction of medium hard to hard friable materials. The dynamically balanced rotor comprises of six replaceable hard faced swing beaters mounted on swinger plates. ...

Rotational speed: 42 rpm - 69 rpm

... Ball Mills are Rubber coated and manufactured in Double and Triple Roll models. The Rolls are 120 mm diameter x 1200 mm long and powered by a 0.37 KW 220 Volt Motor with a variable speed controller. Ball/Rod mill ...

Rotational speed: 600 rpm - 6,000 rpm

Output: 1,500 kg/h

Hammer Mill for the Pharmaceutical Industry Hammer Mill – BTM Mills are used for milling solids. This milling fulfils two purposes: First, it enlarges the particle ...

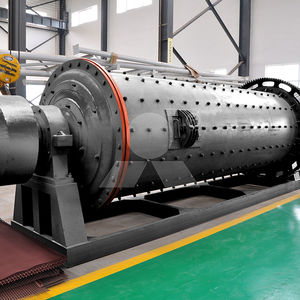

Final grain size: 74 µm - 400 µm

Rotational speed: 21 rpm

Output: 16 t/h - 50 t/h

Ball mill is suitable to grind various mineral and other materials, which is widely used in various industries such as benefication, construction materials, chemical industry, etc, it has two ore grinding ways: dry way ...

Final grain size: 74 µm - 400 µm

Rotational speed: 21 rpm

Output: 16 t/h - 50 t/h

... metallurgy, chemical industry, non-metallic mineral, construction material, ceramics. Working Principle The ball mill is a horizontal rotating device transmitted by the outer gear. The materials are ...

Final grain size: 74 µm - 400 µm

Rotational speed: 21 rpm

Output: 10 t/h - 20 t/h

Ball mill is common used grinding plant in the industry, and it is key equipment used for milling after materials are crushed. This machine can be can grind all kinds of ores and other materials, which is widely used ...

Volkmann‘s Lump breakers for agglomerates and lumps can easily be added to bag unloading and material pick up stations (e.g. RNT, BBU, RNT-CON). They allow vacuum transport in a closed system free of emissions. They are ...

Output: 50 kg/h - 1,500 kg/h

LM series granulators are equipped with rotor and stator knives in a crossed manner for scissor like exact cutting action. This machine helps in finer and identical cutting and keeps the heat formation stable. This type of cutting also ...

NEUE HERBOLD Maschinen-u. Anlagenbau GmbH

Output: 150 kg/h - 8,000 kg/h

These granulators are designed by Neue-herbold. The bearings of the rotor shaft are mounted within solid steel housings which offers more reliable service and eliminate any chance for the housings to crack or break under heavy shock loads. ...

NEUE HERBOLD Maschinen-u. Anlagenbau GmbH

Output: 150 kg/h - 8,000 kg/h

The modern SM1000 series granulator from NEUE HERBOLD features a 1000m rotor diameter in numerous widths. It is ideal for applications that need a huge throughput ability, and where voluminous and generous sized materials need to be ...

NEUE HERBOLD Maschinen-u. Anlagenbau GmbH

Output: 300 kg/h - 1,400 kg/h

Motor power: 7,500, 30,000 W

The grinders of this series are intended for small to medium capacities and are individually designed for the respective product, from pre-crushing for instant coffee production to fine grinding for the espresso and capsule sector. Design ...

NEUHAUS NEOTEC

Output: 750 kg/h - 2,500 kg/h

Most advanced grinder for medium capacities and demanding specialty grinds. The newly designed coffee grinder NEOGRIND has been developed specifically for the high demands of filter coffee, pad/pod production (coffee capsules) and fine ...

NEUHAUS NEOTEC

Output: 0 kg/h - 500 kg/h

Motor power: 2,200 W

When it comes to applications with high demands on the particle size distribution, the laboratory grinder LWM 100 is the optimum machine. The fast roll change resulting from the special roll suspension and the precise control via a PLC ...

NEUHAUS NEOTEC

Designed as an effective sewage grinder and to replace high speed macerators, the SB Muncher can save up to 85% of the energy requirements of a centrifugal force system. Typically it has a cutting tip speed 90% less than a high speed ...

Do you experience frequent ragging and blocking issues in your pumping process? Mono has the solution to this disruptive time-consuming and costly problem with our easy-fit, de-ragging Muncher package. The Muncher is mounted directly ...

... integration with units and systems from key microniser equipment suppliers. As a result, Telstar ACE produces the finest quality milling containment systems that are meticulously tailored to your own facility, operators ...

... rings of segments mounted on carrier discs then air conveyed to a screening machine. The coarse material is recycled to the pulverizer for further size reduction. The desired powder is diverted to fill bags or containers ...

Final grain size: 200 µm

Rotational speed: 80 rpm

Output: 100 kg/h

The PRO100 mill is an eco-designed mill, made in France from recyclable materials. PERFORMANCE Totally autonomous, it will produce 80 to 120 kg of various flours per hour. Suitable for all types ...

Final grain size: 1 cm - 3 cm

... feeding of raw rubber bale into the processing line. It may include mechanisms for weighing, metal decting. Rubber Extruding Chopper Machine: This screw etruding rubber bales to die and cut by rotary knives and the ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining