- Metrology - Laboratory >

- Inspection and Monitoring >

- In-line inspection system

In-line inspection systems

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

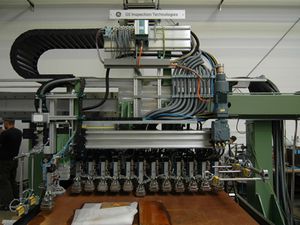

ERW Solutions: In-Line ERW High-Temperature Inspection System Fully Automated ERW Tube Process-Control The In-Line ERW High-Temperature Inspection System integrates into the production line between the weld cooling and annealing, where ...

The bar inspection system (BIS) is a turnkey solution that uses phased array probes integrated into a fully automated testing system to meet stringent quality control standards while maintaining productivity. Key benefits include: In-line ...

In-line ultrasonic heavy plate inspection system Steel plates are the base material further processed into pipes, wind generator towers, ship hulls and a variety of other finished goods. Ensuring this base material is defect free before ...

An ultrasonic strip test system used to inspect coil material prior to forming of Spiral Submerged Arc Welded (SAW) or Electrical Resistance Welded (ERW) pipes. Available as a stand-alone test system or can be integrated into the structure ...

Steel and Aluminum Plate Testing Forging and casting testing for raw materials Waygate Technologies’ line of automated, in-line ultrasonic plate testers span applications from steel used in SAW Pipe to heavy plates used in wind towers ...

VT-X750 is designed with the philosophy to achieve Zero Defect process lines. Traditional X-ray technologies are limited to inspect components like BGAs, LGAs or THT. VT-X750’s design overcomes these traditional shortfalls by incorporating ...

Turnkey Solution for In-Line Inspection of Complex Electromechanical Assemblies. The INSPECT.assembly solution is a fully-integrated inspection station that utilizes a Radiant Vision Systems ProMetric® Y-series imaging system, bright ...

RAYCON EX 1 is a solution that offers maximum performance and ease of use at a moderate price. For all food manufacturers and processors who value a balanced relationship between price, performance and quality. • - Has a 0.8 mm detector ...

The dsound® Tap Check-System detects damaged and defective glass containers and enables a subsequent sorting out. The system is set up on the line and inspects each individual container. With a capacity of 28,000 containers per hour, ...

After GlueChek™ finds a problem with the glue lines, or FoldChek™ identifies manufacturer's joint gap issues by analyzing pictures taken of every box at full production speed, BundleChek™ receives a signal and quickly diverts the bundle ...

Precision and flexibility with AI-enhanced Vision The nLine inspection system analyzes a wide variety of products to determine their quality during ongoing production or individual inspection. Three high-speed cameras continuously ...

Precision and flexibility with AI-enhanced Vision The nLine inspection system analyzes a wide variety of products to determine their quality during ongoing production or individual inspection. Three high-speed cameras continuously ...

ERO-BR verifies that every braille code is correct and conforms to a previous referenced sample. In case a faulty box is detected by the system, the image can be displayed by pressing the appropriate key. Up to 200 images can be saved ...

The Standard Machine for End of Line (EOL) testing, developed by Selmatron, integrates an ESD framework and an efficient barcode reader, representing the ideal solution for performing final tests at your facilities. This equipment ...

SXS2-2154HC1D/SXS2-3474HC1D “Jamming”, “Foreign objects”, “Relative mass”, and “Shape” can be inspected simultaneously with high sensitivity! Hybrid inspection of X-ray and optical system By compositing two images shot with the ...

SE-CT4000 High-Precision Robust Dual X-ray Tube CT System is an advanced device designed for scanning parts to detect defects. Its exceptional high-precision imaging capability renders it an exceptional tool for quality control. SE-CT4000 ...

SE-PCT01 Offline PCB X-ray Inspection Microfocal CT System takes advantage of the characteristics of high-resolution pulse emission and high brightness of carbon nanotube CT tube. A quality monitoring method for finding hidden defects ...

SE-PCT02 Industrial High-Precision CT Tomography Inspection System. A cutting-edge 3D X-ray inspection solution designed for the PCBA and IGBT fields. Utilizing advanced computer tomography (CT) scanning modes and reconstruction algorithms. ...

The inspection system ColourBrain® DrillCheck 4.0 is the technological leader in the inspection of drill hole patterns for furniture components. Deviations in the pattern and grooves are reliably detected, visualized and alarmed. The ...

The IX-EN range of X-ray inspection systems offer you a high-quality entry point into advanced foreign body detection in food products. It is easy to set up and integrate into your full production line. The IX-EN delivers accurate ...

A range of tunnel solutions for any logistics application Cognex Modular Vision Tunnels elevate the speed and efficiency of sortation, inbound receiving, and outbound logistics operations. These flexible scan tunnels offer 1–6-sided ...

Surface Defect Inspector – Single View The single-camera surface defect inspector (SI1100) captures, analyzes, and judges the surface of welds or flat products such as bars, tape, or profiles. The SI series is the most thorough method ...

Finding leaks and closure faults: leakage check for plastic bottles. Tracking down minute leaks reliably: the HEUFT squeezer QS ensures the microbiological purity of sensitive drinks by identifying leaking PET bottles in-line and removing ...

HEUFT SYSTEMTECHNIK

ultrasonic inspection systemDELAMINATIONCONTROL F

The ultrasonic measuring system GreCon DELAMINATIONCONTROL F detects inhomogeneities in panel-shaped materials, such as wood based panels, inline. Size and location of defective areas are recorded and visualised. Thus, defective panels ...

Fagus-GreCon

100% inspection systems are becoming ever more important due to the high requirements in the labeling market. The consequence of the challenging requirements is that, in many areas, goods may not reach the ultimate consignee without a ...

Erhardt + Leimer

3D In-line Paste Inspection System The unique 3D process for the acquisition and measurement of screen printed volume guarantees reliability and repeatability of high quality. The choice of resolution for the purpose or not standards ...

OMRON EUROPE BV Omron AOI Business Europe

Seal-Inspect is an out-of-the-box solution designed to identify sealing faults of packaging in real-time in manufacturing lines. The solution includes thermal camera and VIDIA innovative software algorithm for visual inspection and can ...

CALIPRI C11 and CALIPRI C15 are hand-guided gap & flush measuring system for taking continuous inline measurements . The systems are designed for extremely simple operation and most accurate results. Choosing CALIPRI means you can ...

NEXTSENSE GmbH

The solder joint inspection system ViproColour Inline is designed for high volume and inline productions. However, different methods of programming allow an easy and fast setup of test programs for different sizes of batches. For ...

The systems are used in cable, pipe and hose production as well as in the control / inspection / testing / sorting of individual parts such as sleeves, bolts, pins or rods. Also for endless products The most important features of the ...

PREFORM INSPECTION MACHINE Ideal to ensure the quality of the final product and reduce both the number of jams along the line and rejects produced during the blow molding phase due to defective preforms. The inspection system comes ...

FT SYSTEM

Your suggestions for improvement:

the best suppliers

Subscribe to our newsletter

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining