- Industrial machines and equipment >

- Furnace and Heat Treatments >

- Induction oven

Induction ovens

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

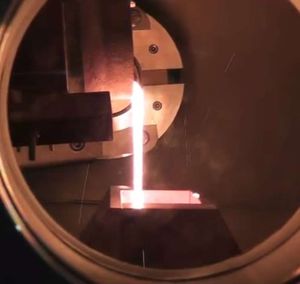

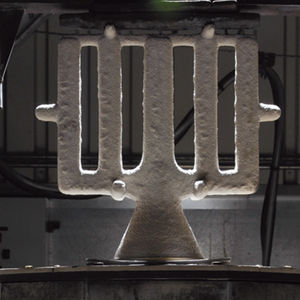

Vacuum Induction Melting furnace for production of directionally solidified or single crystal castings. JetCaster VIM DS/SC DGCC is used for production of high quality precision turbine blades castings ...

VACUUM MELTING FURNACE SYSTEMS Vacuum melting technologies and equipment Vacuum metallurgical equipment is manufactured in our facilities in the United States, Poland and China, which are the regions with the highest ...

... the first single-crystal turbine blades and continues to provide high-yield furnaces with low operating costs. Retech Cold Wall Induction (CWI) furnaces, also called Induction Skull ...

Maximum temperature: 1,200 °C

TIP furnaces are designed to manufacture any size of ingots, from 100 g to kilo-bar either in gold or silver. Ingots are obtained by melting pre-weighted grains in a graphite mould placed inside the vacuum chamber and ...

Topcast Srl

Maximum temperature: 1,250, 1,600 °C

Capacity: 500 cm³ - 7,000 cm³

Vacuum Casting Machine for Sheets and Rods This family of furnaces are used to produce high quality semi-finished product, like sheets or rods, starting by raw materials melted by induction heating ...

Topcast Srl

... examples of TVM typical usage. Description TVM furnace is conceptually divided into 4 sub-systems: 1. Vacuum Melting Chamber with optional alloy feeding chamber 2. Induction Generator 3. Tilting ...

Topcast Srl

Maximum temperature: 1,450 °C

... crucible is cleaned and new refilled with glass. MSE designs and manufactures up to 1450°C in different nozzle diameters and induction heated glass fiber production systems without sacrificing safety and quality upon ...

Maximum temperature: 1,450 °C

... CAPACITY 5 KG AU/750 POWER 5 KW MAX TEMPERATURE 1450° STATIC INDUCTION FURNACES CRUCIBLE CAPACITY 11 KG AU/750 POWER 10 KW MAX TEMPERATURE 1450° STATIC INDUCTION FURNACES CRUCIBLE ...

Maximum temperature: 1,450 °C

CRUCIBLE CAPACITY 40 KG AU/750 POWER 20 KW MAX TEMPERATURE 1450° TILTING INDUCTION FURNACES CRUCIBLE CAPACITY 70 KG AU/750 POWER 40 KW MAX TEMPERATURE 1450°

Maximum temperature: 0 °C - 100 °C

... Nordson® induction side-seam pre-cure system can increase curing capacity and line speeds by as much as 20 percent, without increasing the capacity of an existing oven. The compact unit preheats the weld ...

Maximum temperature: 1,800 °C

... treatment of bulk materials (powder, granules, fiber, waste) Resistance heated with FeCrAl-, APM-, MoSi2-heating elements Induction-heated Microwave-heated Hybrid heating (microwave/ resistance heating, resistance/ ...

Linn High Therm

Maximum temperature: 1,600 °C - 2,200 °C

Capacity: 34 l - 338 l

... heat treatment furnaces with high operating temperatures specially for the manufacture of hard materials. Standardized components for a broad application spectrum and useful space volumes from 34 to 338 litres. Applications: IOV ...

PVA TePla Group

... products incorporates a Stein reheat furnace with CELES high-flux inductors for sizable cost & energy savings and improved product quality. Fives has developed a new hybrid solution combining a gas-fired Stein reheating ...

Capacity: 0.3 l - 3 l

The heating system of GW series of intermediate-frequency coreless induction melting furnace produced and manufactured by our company, is designed and developed with a combination of absorbing the latest ...

The induction heating systems SOUCURE LI consist of the following components: Modular machine frame Magnetic textile conveyor belts Induction elements, no water cooling requested Central diameter adjustment Prepared ...

Roll-over melting furnace Ideal for high-precision melting and pouring, and for investment casting applications. High-frequency power sources ensure short melt times (and eliminates oxidation). Mould filling is extremely ...

EFD Induction Group

... 's coreless induction furnaces offer superior performance and outstanding durability for all your melt shop needs regardless of the size of your molten metal needs. From small capacity, precision casting ...

Inductotherm

... coreless melting furnaces provide superior performance and outstanding durability for all your melt shop needs, regardless of the size of your foundry. Inductotherm Group companies offer a range of furnace ...

Maximum temperature: 0 °C - 1,500 °C

Induction melting furnaces are a modern and economical alternative to electric resistance, gas and oil furnaces. New technological solutions give wide possibilities to the user. An indispensable advantage ...

Argenta

... efficiency...: coreless induction furnace or HIC have been replacing cupola furnaces in most iron foundries. When subjected to a rapid rise in temperature, the lining must respond ...

INSERTEC INDUSTRIAL FURNACES INSERTEC, S.L.U.

Maximum temperature: 1,150, 1,100 °C

... complete range of sampling furnaces for scrap metal. These small, low-investment furnaces allow you to quickly melt all types of scrap metal and then extract the chemical composition and metallurgical ...

HORMESA CONTICAST HORNOS Y METALES S.A.

Maximum temperature: 0 °C - 1,350 °C

Made with Fossati certified High Refractory material and protected by AISI Metallic Carpentry.

OTTO JUNKER MF induction furnaces are proven and versatile solutions refined over many years. Designed for melting, holding and pouring any type of metal, these high-performance systems embody state-of-the-art ...

OTTO JUNKER GMBH

Constructed to meet the user’s needs, sizes equipment etc. Easy to deploy. Forced air induction for better circulation. For over-sized items like drums, pallets or trays: Can be supplied with rails for loading cars, ...

... uniform precision and solid-state induction to braze conductive materials with in a tightly controlled atmosphere. The unique relationship balance of time, temperature, and atmosphere in a Control Atmosphere Brazing (CAB) ...

The Furnace 6 by Aseg Galloni Spa is a melting furnace which is just easy to use because of its use-friendly controls. For this specific unit, it comes with a high melting speed that can melt a 6 kg ...

ASEG GALLONI SPA

This oven has been designed for heating brass bars with an integrated shear cutting system. The INDUCTION heating system guarantees effective heating of the entire bar and the burr-free cutting system ...

FARM NEW BRASS s.r.l.

Maximum temperature: 1,600 °C

... electric furnace rated capacity:13000kVA,3000KVar rated power:2×6000kW,8000~12000KW Induction Melting Furnace,Medium Frequency Power Supply,Power Transformer 1.GENERAL The melting induction ...

Shanghai Electric Heavy Machinery Co., Ltd.

Maximum temperature: 900 °C - 1,800 °C

500KG Induction Furnace for Melting Scrap Steel, Iron, Copper, Aluminium The induction furnace body mainly includes: Open furnace body, furnace ...

Tangshan Juntong Technology Co., Ltd.

Consarc offers Induction Skull Melting (ISM) furnaces which is a method of melting metals in a segmented water-cooled copper vessel while under vacuum or controlled atmosphere using an induction ...

CONSARC

Your suggestions for improvement:

An induction furnace is an electric apparatus used to melt metals, and whose heat is produced by induction. Electromagnetic induction provides non-contact heating of conducting materials. This phenomenon occurs when a conductive object is placed in an electromagnetic field created by a solenoid. The current generated within the material generates heat.

Induction heating is a clean technology which produces less pollution and dust than combustion or arc furnaces, or other foundry processes. Such furnaces are used to melt precious metals, aluminum, copper, cast iron and steel. Their capacity ranges from one kilogram to a hundred tons.

These furnaces are used in numerous domains, from jewelry making to iron and steel mills.

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining