- Industrial machines and equipment >

- Surface Treatment >

- Industrial galvanizing

Industrial galvanizing

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

This Multifunctional Washer is made of high-quality iron and its surface is galvanized to enhance its corrosion resistance. The galvanized layer not only improves the durability of the washer, but also gives it a smooth appearance, suitable ...

Turning Parts, Metal Parts Manufacturer, Custom CNC machining parts. According to customer requirements, galvanized surface treatment of product raw materials •Material: Steel, Brass, Aluminum, Stainless Steel •Surface Treatment/Finishing: ...

BIEBER Industrie has been able to grow a 21,000 m2 industrial site, in Drulingen, Alsace France. The reworking of the workshop, providing an adjustable workplace for soldering, assembly and finishing touches, allows ...

The highest corrosion protection for your steel. Hot-dip galvanising guarantees perfect all-round protection of your components. In hot-dip galvanising, the pretreated steel parts are immersed in a molten zinc liquid that is heated ...

Hot-Dip Galvanizing or HDG is a process in which zinc bonds to steel at the molecular level to produce a four-layer corrosion-resistant finish. The first three layers are zinc-iron alloy layers that are actually harder ...

SUTOR TECHNOLOGY CO., LTD

... can also be reliably protected. In the area of hot-dip galvanizing, we offer a unique, self-developed coating process using the rack process. The parts – such as screws for the wind power industry – ...

... production lines are: The first large galvanizing pot is 13.5 meters × 2.5 meters × 3.8 meters; The second medium-sized galvanizing pot is 7.5 meters × 1.8 meters × 2.2 meters; The third small ...

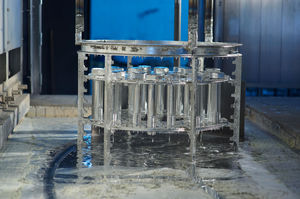

Electrogalvanizing of rack objects For all kinds of machine components and technical items electrogalvanizing with varied chromating is still the most frequently-employed protection against corrosion. This process is ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining