- Production Machines >

- Plastics Processing >

- Injection molding for the automotive industry

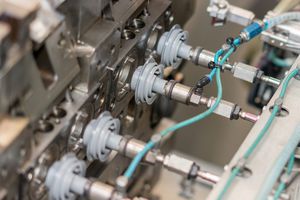

Injection molding for the automotive industry

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

... offer the manufacture of your molded silicone parts and seals in ISO 7 clean room in injection molding, and in an industrial environment in compression molding as injection. The ...

Injection Moulding The classic manufacturing process for thermoplastic products. By designing the injection tools based on the specific product requirements and by defining the correct ...

Helvoet Rubber & Plastic Technologies B.V.

Injection Moulding The classic manufacturing process for thermoplastic products. By designing the injection tools based on the specific product requirements and by defining the correct ...

Helvoet Rubber & Plastic Technologies B.V.

Injection Moulding The classic manufacturing process for thermoplastic products. By designing the injection tools based on the specific product requirements and by defining the correct ...

Helvoet Rubber & Plastic Technologies B.V.

Our Industry Business Unit develops and produces high-performance global solutions for our partners in the mobility, construction and equipment sectors. Our ambition is to support them in their digital and ecological ...

... TECHNOLOGIES Mono-material injection Component overmoulding Bi- and Tri-injection Co-injection Heat and cool (Roctool) Gas injection Injection ...

Adopts plasticizing and injection completely separated, first-in-first-out (FIFO) method. Precise injection volume,minimum injection runner length, and floating-type nozzle ensures excellent ...

Injection is a mastered technical field, mature, subject to strong international competition. Dedienne MULTIPLASTURGY® Group mobilizes its Research and Development teams to offer its customers differentiating technologies, ...

... critical parts. 3P works for all kind of industries: aeronautic, automotive, energy, medical, houseware...

3P Produits Plastiques Performants

... materials, injection moulded parts can have custom finishing, polishes, or surface textures. Xometry offers both high-precision tool manufacturing and injection moulding services. Xometry Injection ...

Xometry Europe

Full process and cost management Our competence, employee commitment, process flexibility, top quality equipment maintained at a high level of availability, mould expertise, structured organisation and ...

... plastic injection parts rather invariably leads to high investment in tooling which may impact your project viability from the start. That is why we offer very low tooling costs to our customers, while keeping high competitiveness ...

Injection Capabilities and Facilities KJI's injection plant is ISO-9002 certified. Along with efficient management, we have injection machines that range from 180 tons to 1360 tons, ...

... specialises in designing tools and has a machinery fleet of 100 automated vertical and horizontal injection presses (pressure of 22 to 500 T – injection of 1 to 150 grammes) divided ...

Mold Type - Plastic injection mold, overmolding, Interchangeable Mold, insert molding, compression mold, stamping, die casting mold, etc Design software - UG, ProE, AutoCAD, Solidworks, etc Main services ...

ERBIWA MOULD INDUSTRIAL CO.,LTD.

NingBo ChenTe electronics Technologies Co.,Ltd

... Automotive Injection Mold Here are three major features of using automotive injection molding for manufacturing injection moulding car ...

... The semi-finished product with a dough-like consistency can be processed using compression, injection molding, transfer molding and injection compression molding ...

... technical/special item with any shape and any compound and to have a complete internal production process. The manufacturing process is carried out in compliance with high quality and certified standards and it is based ...

Mould-Precision Stamping Mould Mould Material: <300℃ Zinc AlloyCr12, Cr12MoV, S-136, SLD, NAK80, GCr15, T8, T10 300~500℃ Aluminum Alloy, Copper Alloy 5CrMnMo, 3Cr2W8, 9CrSi, W18Cr4V, 5CrNiMo, W6Mo5Cr4V2, M2, 500~800℃ Aluminum Alloy, ...

... into the mold cavity. The mold remains relatively cold so the plastic solidifies almost as soon as the mold is filled. This process has six stages: Vacuum mold closure. Inject the material, forcing it to ...

Emergency switch for the disabled, which can be used in hospitals and nursing home etc.

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining