- Production Machines >

- Other Manufacturing Equipment >

- Ion beam-assisted deposition machine

Ion beam-assisted deposition machines

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

... in the past 3 years and successfully designed and fabricated high efficiency, commercialized and standardized sputtering deposition systems. We firmly believe that this technology will disrupt the vehicles industry. ...

Shanghai Royal Technology Inc.

PECVD & Magnetron Optical Films Deposition System Polyhedron Structure Vacuum Coating Machine The Multi950 machine is a customized multiple functions vacuum deposition ...

Shanghai Royal Technology Inc.

RTEP1616-SPDC Vacuum Metalizing Machine is specially designed for EMI shielding thin film deposition, which is widely used in telecommunication devices, computers, notebooks, consumer electronics, home ...

Shanghai Royal Technology Inc.

Chrome plating is a film surface treatment, which has been commonly used in many industrial sectors, to provide excellent shiny decoration, which prevented corrosion and abrasion. However, the hexavalent Chrome electroplating (Cr6+) ...

Shanghai Royal Technology Inc.

... Sputtering System with the PECVD (Plasma Enhanced Chemical Vapor Deposition) Technology to deposit high uniformity, strong adhesion SiC thin films. The Hydrogen fuel cell sputtering machine contains ...

Shanghai Royal Technology Inc.

... products etc. Rose Gold Arc Ion Plating Machine has features of: fast deposition, strong adhesion, bright colors, easy operate and low power consumption for a beneficial coating ...

Shanghai Royal Technology Inc.

... manufacturers etc. Features: 1. This machine is equipped with E-beam gun, crucibles, tungsten boats. In the entire evaporation process the film surface is flat and evaporation distribution is even. 2. ...

Shanghai Royal Technology Inc.

... Vacuum Metalizer The glass lighting reflector thermal evaporation coating machine hight features are: 1. Top coating for a high uniformity of film deposition; 2. Ion source ...

Shanghai Royal Technology Inc.

... multi-pressure zones to accommodate various deposition sources. B. Multi-Source simultaneous deposition capabilities in one web pass, for multi-layer coating. C. Reversible web winding direction enables ...

Shanghai Royal Technology Inc.

... films deposition. The high uniformity film's deposition system have been serving several industries like Electronics parts, medical instruments components which require high film uniformity, multiple ...

Shanghai Royal Technology Inc.

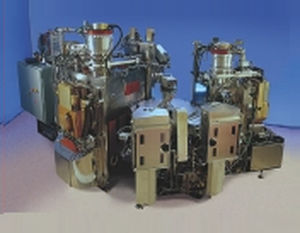

... is a PVD deposition machine that is assisted with an ion beam. It is capable of achieving optimum levels of productivity by providing maximum through-put ...

VEECO

SPECTOR Loadlock Ion Beam Sputtering System for Optical Coating Superior Throughput and Repeatability for a Wide Range of Applications Veeco's SPECTOR® Loadlock Ion Beam ...

VEECO

This IBAD ion beam assisted PVD deposition machine is developed by VEECO. It is specifically designed to cater applications that include ...

VEECO

... even a high-end productive solution for standard and ion-assisted coating processes for mid-sized production batches. Sustainable solution due to modular design Upgrades related to the electron-beam ...

Bühler Leybold Optics

... delivers outstanding performance The BOXER series features a high-powered electron-beam gun positioned in the center of a coating chamber, assuring uniform deposition of the coating materials onto the ...

Bühler Leybold Optics

... meet future demands and will continue to set quality benchmarks. Different machine types and sizes provide high productivity By offering different chamber sizes, SYRUS machines can be adapted for individual ...

Bühler Leybold Optics

... short and long pass), UV–IR cut filters, notch filters and narrow band-pass filters, dichroic color filters and polarization beam splitters, AR and HR coatings for lasers and many more. Every SYRUSpro is equipped to the ...

Bühler Leybold Optics

... coating equipment, through cathodic arc, high-power intermediate frequency sputtering and DC sputtering, auxiliary high-voltage ion bombardment and pulse bias, the coating is denser, and the adhesion and gloss are increased. ...

Powertech

Scientific research coating equipment Experimental vacuum coating equipment has the characteristics of beautiful appearance, compact structure, diverse performance, simple and reliable operation, and low power consumption. It can realize ...

Powertech

... preparation of anticorrosive coatings on the surface of magnetic materials, through magnetron sputtering, evaporation, electric arc, ion bombardment, etc., rapid plating of aluminum/alloy, titanium, chromium and other ...

Powertech

Can be integrated in existing MBRAUN gloveboxes (through antechamber) • For substrates up to 50 x 50 mm wafers • Compact design • Economic solution • Short delivery time • Fast and easy installation • Easy retrofit in existing gloveboxes • ...

Mbraun

... cost-effective solution • Easy configuration design • Co-deposition • Uniformity up to +/-3 % (with specific geometry design up to +/1 %) • Two standard-sizes: PROvap 4G and PROvap 5G • Up to 8 deposition ...

Mbraun

... solution • Easy configuration design • Co-deposition is possible • Uniformity up to +/-3 % (with specific geometry design up to +/1 %) • Two standard-sizes: UNIvap 4S and UNIvap 5S • Up to 8 deposition ...

Mbraun

• Flexible, modular system • Stand-alone (S) or glovebox integrated (G) • Building block for cluster tool • Multi-substrate & multi-mask processes • Standard uniformity: +/- 3 % (with specific geometry design up to +/1 %) • Substrate ...

Mbraun

Mini PVD Chamber 100% dedicated to Perovskites • Can be integrated in existing MBRAUN gloveboxes (through antechamber) • Compact design • For substrates up to 50x50 mm • Up to 4 sources • Layer uniformity < +/-5 % • Economic solution • ...

Mbraun

... efficient R&D • Special system design • Special precursor source • High stability at low temperature • Stable and defined deposition process • High vacuum conditions • Low cross-talk • High repeatability • Material ...

Mbraun

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining