- Production Machines >

- Other Manufacturing Equipment >

- Large series forging

Large series forging

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

... we are qualified with IATF16949&ISO13485, which is the higher quality management system. • Material: Brass • Process: Stamping • Application: Electrical switches •Requirements: No Burrs, Scratches, Dents, Pits •Packing: ...

HLC METAL PARTS LTD

This Aluminum Plate is crafted from high-quality aluminum and finished with a clear anodized surface that enhances durability, corrosion resistance, and a sleek appearance. Designed with precision, it offers a tolerance of ±0.1mm, ensuring ...

HLC METAL PARTS LTD

20+ years experience in metal parts field manufacturing,we are qualified with IATF16949, which is higher quality managerment system. The accessories we produced are widely used in the fields of electronics, electric device, communication ...

HLC METAL PARTS LTD

In close collaboration with the customer, solution-oriented process stages are developed and optimally adapted to the customer's individual requirements. By this process, the HEICO group is able to replace castings and turned parts with ...

Hot die forging consists in shaping blanks, after prior heating, by pressing them between two blocks (the dies) with moulds of the preliminary or the near-net shape of the product to be manufactured. The hot forging ...

Groupe SIFCOR

Nine production lines with presses between 500 and 2,500 tons, fed by four cold shearing lines: this system is active on two shifts, capable of punctually and flexibly meeting the most diverse range of needs. All lines are equipped with ...

FACEM

Matson Metal is a supplier of OEM valve castings with machining service in China. With 20 years' experiences in this industry, we focus on and have advantages in the following aspects: engineering - Review and evaluate your drawings ...

Hebei Matson Metal Tech Co., Ltd.

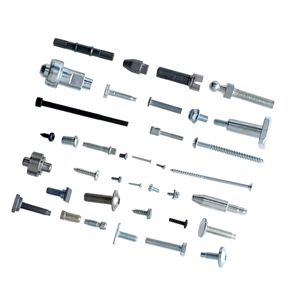

For the manufacture of metal parts, screws and rivets, ETMA has the capacity to work wires with a diameter between 1.5mm and 12mm in double blow and multi slide horizontal presses and in a variety of materials. We can finish the forged ...

ETMA METAL PARTS

CLOSE-DIE FORGING AND HOT EXTRUSION Manoir Industries is one of the european leaders in forging with heavy stamping and hot extrusion, specialising in the production of complex forged ...

... only some of them. Stamping consists on compressing a specific metal between two moulds. There are two types of stamping: the progressive stamping and printing by percussion. In progressive type, compression ...

GESTION DE COMPRAS

... control system. The technical performance levels associated with fitting and assembly enable the completion of medium to very large production runs (tens of thousands or even millions of parts). LEMAN Industrie’s policy ...

LEMAN INDUSTRIE

... 1030, C45 • Alloy steel: 18CrNiMo7, 40Cr, 42CrMo • Stainless steel: SS316, SS304 • Aluminum alloy Process: • Open die forging + machining + • heat treatment Size: • Medium: 100kg to 1ton • Big: more than ...

ZS Industries Co., Ltd

WE ARE FORMING METAL The challenges of our customers rise on a daily base. Therefore it's vitally important to coordinate ail aspects of the manufacturing technologies. Stamping, bending, clinching and threading are the techniques we ...

WINFRIED KEINE METALLVERARBEITUNGSGES. mbH

The Sheet Metal Forming Dpt. for Shearing and Deep-drawing is equipped with presses ranging from 15 Tonnes to 400 Tonnes, fitted out for automatic machining with conveyor belt feed lines. Sheared and Deep-drawn components are produced ...

Pump shafts for volute casing pumps in various diameters and lengths, from forging production, including heat treatment. Pre-processing according to customer drawing. Raw material available from stock. Approval according ...

... of mechanical and automatic presses, Filame can assist you with your need for cut and/or drawn parts in small, medium or large series. Our tooling workshop is used to develop solutions to meet the volume ...

Filame

Stamping tools: Progressive Stamping Single Hit Stamping Transfer Stamping The thickness of the molded material is in the range of 0.5 – 2.0 mm. The material ...

Your suggestions for improvement:

the best suppliers

Subscribe to our newsletter

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining