- Production Machines >

- Textile machinery >

- Liner production line

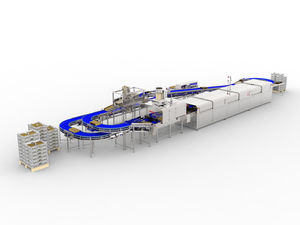

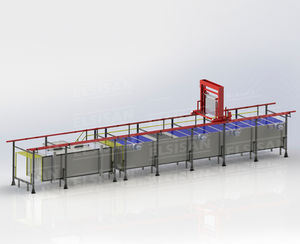

Liner production lines

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

... YONGKE offers four sizes of wet out liner machine and all come with the our many years experiences and know-how. UV-CIPP liner production line includes dry liner ...

... years! UV-CIPP Liner is constructed with a puncture-resistant, removable inner foil, high quality, corrosion-resistant fiberglass, and advanced UV resins - proven to be one of the strongest products on the market. UV ...

... YONGKE offers four sizes of wet out liner machine and all come with the our many years experiences and know-how. UV CIPP liner production line includes dry liner ...

Covering machine, for the production of fancy yarns for the trimming industry, shoes industry and for the production of special yarns. Possibility to work from any kind of yarns, including metallic ...

In-line physical coating equipment for Transparent Conductive Oxide (TCO) coating on wafer,glass plate or flexible substrate. • Magnetron Sputter (PVD). • Reactive Plasma Deposition (RPD). • Multiple cathode ...

Roll Coater Type SC-CCP120, Ceramic Transfer Paper Coating Drying Line SC-CCP120 ceramic transfer paper coater is a newly developed coating machine. It is mainly used for roll coating on ceramic transfer paper, kraft ...

Guangdong Shanzhang Industry Co., Ltd.

The SSM GIUDICI NOVA-CS conventional single covering machine is designed for the production of high quality elastic covered yarns ranging from fine to medium final counts. The key features are: Inverter driven motors ...

SSM

Working width from 1.6 meters up to 5 meters Available configurations: Knife – Model TR Kiss roller – Model TRI Knife + Kiss roller combined -Model TRC Knife over air or knife over roll coating options Application of paste or foamed ...

... reduce the investment scale under the premise of ensuring quality, make the spraying line rank advanced in the same industry, and products meet international The coating line is energy-saving, environmentally ...

guangdong chuangzhi machinery equipment co..ltd

Features: Batch size: 112 lenses (up to 90 diameter) Per Hour: 1,120 (lenses) x2 Robotic Transporter Systems Three ultrasonic cleaning (detergent) plus three stages plus ultrasonic rinsing. All clean and rinse stages are fitted with ...

Optimal Technologies

... the first mixer is transferred to a second liquid-cooled mixer which allows to complete the coating process in an optimal way lowering the production time.

Non-grain-oriented strip is annealed in a radiant tube furnace using a continuous process after cold rolling to ensure recrystallization and controlled grain growth. Top-quality steel requires strip temperatures ...

LOI Thermprocess - Tenova Metals Division

... manual spraying to automatic spraying, line 01 is the right choice. It is the most cost-effective solution in ways of saving paint, saving labor and increasing productivity. The automatic spray coating line ...

Guangdong Richfruits Coating Technology Co.,Ltd

- Modular Design - Cleanroom class ISO 8 or higher - Line automation system - Wide product range - Fully automated plasma coating process - High resolution roughness measurement (0.1 µm) ...

PVC Coating Line For Welded Wire Mesh In Rolls 1.preheating furnace Making the welded wire mesh into the preheating furnace warming.Adjust the temperature to 300-480 Degree as the wire diameter .Then it will be keep ...

Roll-to-Roll plant close to production scale The Linecoater is a robust pilot coater that makes it possible to run roll-to-roll coating processes on a near manufacturing scale. The standard 3,000 mm ...

... flexible, small-batch production. Its strict modular design enables it to meet rigorous requirements in both development and production. ROENERT has developed the compact LABCO for effective product ...

... plates which is done by the centrifugal force due to high speed rotation. It is a highly useful equipment in plate making process and are essential to make a high quality plate. As the coating is done by centrifugal rotation, ...

Optional machine widths ; 1800mm – 2000mm – 2200mm – 2400mm – 2600mm • 2 different blade working style • The blade is movable on the machine • Under cylinder covered with hard chromium • On the cylinder and on the air coating style • ...

Semi-automatic or/and automatic cheese surface coating line consists of a conveyor belt set, painting tunnel with special sprayers, cheese flipper and a tunnel for drying the external surface.

Tumbler Coating with Liquid Nitrogen High quality and easy preparation of meals, especially ready-to-serve meals, are increasingly important criteria which the consumer expects from the manufacturers. To cater for this demand a system ...

... pretreatment should be made properly. Therefore, the pretreatment line comprising degreasing and zinc-phosphate tanks is required before the cataphoresis application. These pretreatment lines can be with ...

... strong growth in single serve PET bottle formats, which represent big challenges when it comes to long-term beverage quality, production cost, efficiency and reliability. Nearly 30 Actis systems have been introduced ...

... surface coating also protects the cheese fromfungal attack and from drying out during ripening.Designed for small to medium production rates, this semi-automatic cheesecolouring unit provides full surface coating regardless ...

Mass coating of small parts using the hot drum process Coating with the Rotamat is the economical solution for the surface finishing of mass-produced small parts made of elastomers, metal or wood - for example, O-rings, ...

... is equipped with haul-offs which pull the pipe at the same speed as the extrusion line. The pipe is covered in material in a continuous mode. The welding is also continuous and is performed ...

Summary Coating method: Wide and high-speed double-surface coating, front and back coating heads work at the same time, once coated on both sides, coating speed can reach 80m/min, mechanical speed 100m/min. Coating die: adopts Domestic ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining