- Metrology - Laboratory >

- Inspection and Monitoring >

- Lubrication monitoring system

Lubrication monitoring systems

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

... Grease Caddy is designed to optimize time-based lubrication. The Ultraprobe 201 allows an operator to simultaneously lubricate and monitor ultrasound levels in bearings, keeping you from over lubricating ...

... Caddy removes the guesswork of lubrication by allowing you to monitor the friction in your bearings, ensuring you are applying the right amount of lubrication. By moving from time-based monitoring ...

... when friction levels increase, guides you during re-lubrication, and prevents over and under lubrication. LUBExpert is an ultrasound solution that helps you Grease Bearings Right. Use the right lubricant ...

SDT Ultrasound Solutions

... applications in your plant: - Mechanical Condition Monitoring Identify early-stage bearing defects to prevent unplanned failures. - Bearing Lubrication Monitoring Verify optimum ...

SDT Ultrasound Solutions

... applications in your plant: - Mechanical Condition Monitoring Identify early-stage bearing defects to prevent unplanned failures. - Bearing Lubrication Monitoring The right amount ...

SDT Ultrasound Solutions

The A4910 Lubri is a maintenance tool used for monitoring and control of the lubrication process. The A4910 Lubri measures the actual bearing lubrication status and informs ...

... critical point) - continuos control & monitoring of con-rod bearing and oil temperature by Wireless & Batteryless Sensing Node with Energy Harvesting System, and transferring all ...

RAEM1 system is a complete full function IIoT-AE system designed for remote unattended acoustic wave (acoustic emission) long term non-destructive testing and condition monitoring applications. ...

... bridge structure health monitoring, storage tank corrosion monitoring and other applications to predict and alarm early fault detection and maintenance. Features: • Standalone system, ...

RAEM2 is an all-in-one condition monitoring system, combining acoustic emission (AE) sensor, battery, data acquisition and process module and communication modules in a small aluminium alloy cylinder. ...

... Application • Vibration monitoring in time or frequency domain • Monitoring of vibration velocity (severity) of rotating machinery to ISO 20816-1 (formerly ISO 10816-1) and reciprocating engines to ...

Metra Mess- und Frequenztechnik in Radebeul e.K.

... accurately. Your systems can now run at normal and even improved vacuum levels to improve power turbine efficiency. Costs The cost of a high end ultrasound detector is 3 to 5 times less than the ...

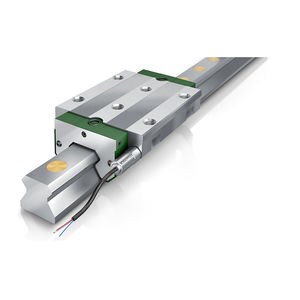

... security DuraSense monitors lubrication conditions in linear guidance systems and triggers the signal for a relubricating impulse from a relubrication unit when, for example, insufficient lubrication ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining